Mounting structure and method for container building peripheral guard plate

A technology for installing structures and enclosure boards, applied in building components, building structures, buildings, etc., can solve the problems of troublesome replacement, affecting the use effect, easy to deform, etc. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

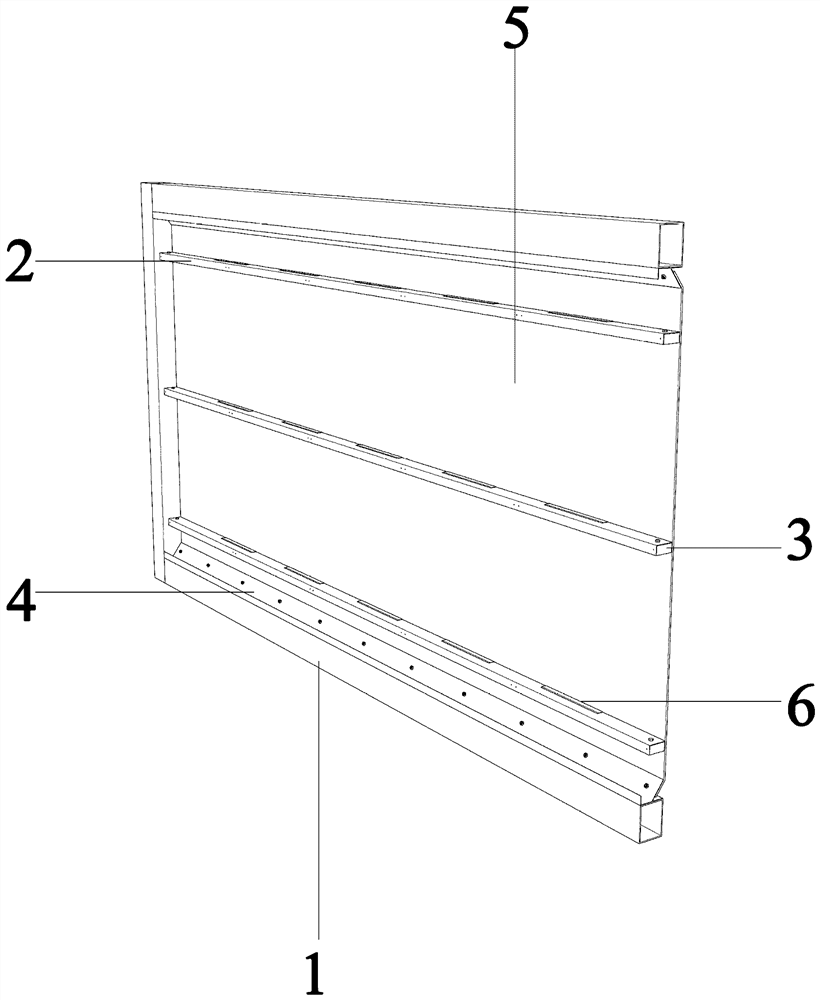

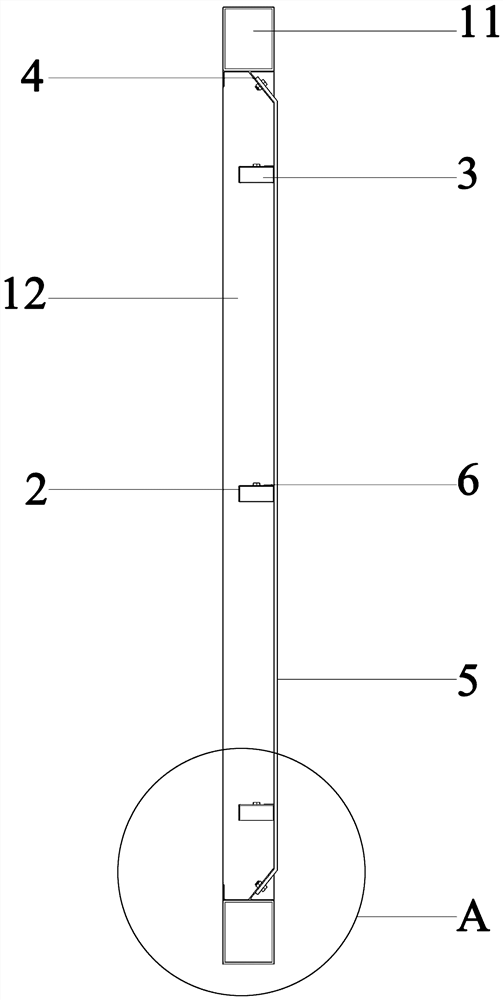

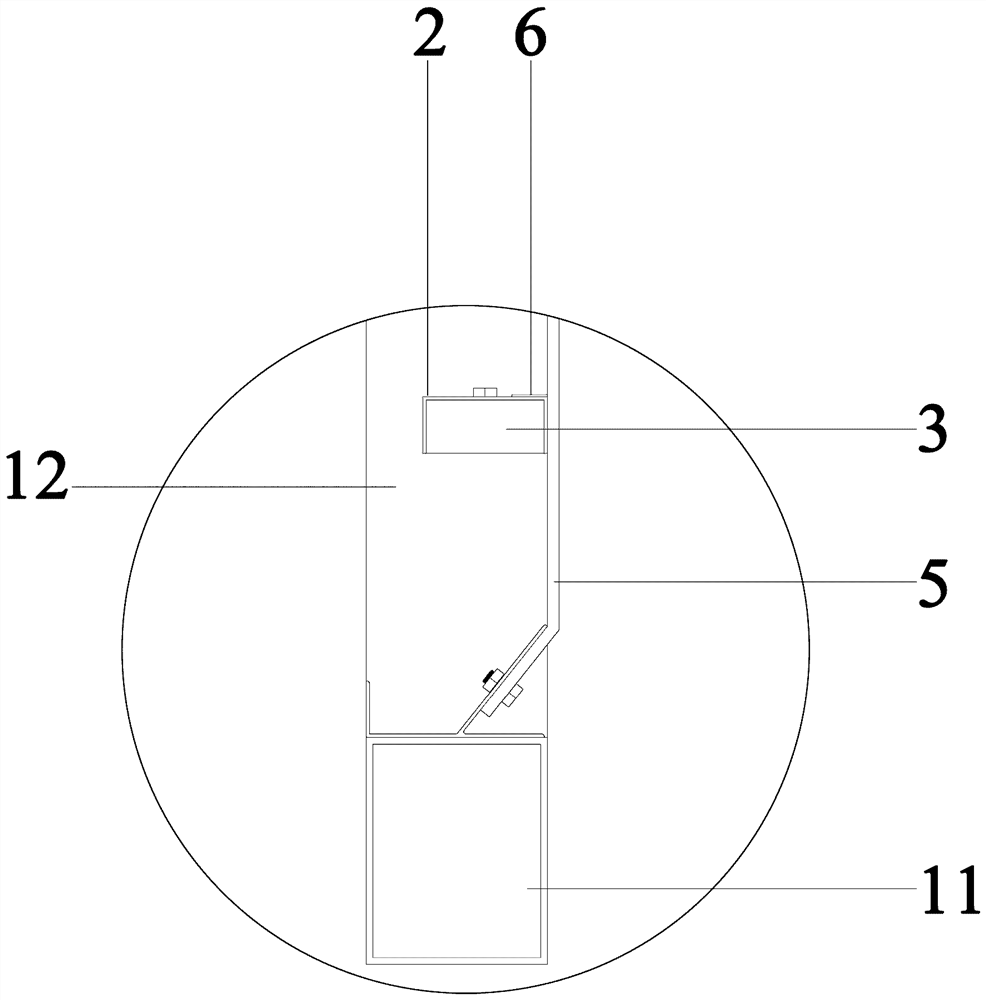

[0039] See Figure 1 to 8 The mounting structure of a container building peripheral strobe provided in the embodiment of the present invention includes a structural frame 1, a structural frame 1 comprising two up and down intervals provided with two vertical frame beams 11 and two vertical welding The frame column 12 on both ends of the frame beam 11 is provided with a plurality of support beams 2, and both ends of the support beam 2 are connected by the L-shaped angle member 3 and the frame column 12 on both sides; the connecting strip 4, which is The "knife" word type metal line, the connection strip 4 symmetrically welded the inner side of the two frame beams 11; the enclosure 5 includes a rectangular envelope body 51, and the two long sides of the enclosure body 51 respectively Extended, the first mounting plate 52 is formed, and a circular first mounting hole 521 arranged in a plurality of specifications is opened on the first mounting plate 52.

[0040] The mounting structure...

Embodiment 2

[0047] See Figure 1 to 8 The mounting structure of a container building peripheral strobe provided by the second embodiment of the present invention is shown, and the present embodiment further makes the following as an improved technical solution based on the above embodiments: support The beam 2 includes a rectangular beam body 21, and the two long side of the beam body 21 is opposed to the first flange 22 and a second flange 23; the first flange 22 is opened with a number of circles for fixing the decorative wall panel. Wire hole; the beam body 21 is opened on a plurality of specifications arranged, and the top of the beam body 21 has a circular first bolt hole 212; the angle member 3 includes a first fixing plate 31, first One end of the fixing plate 31 extends vertically to form a second fixing plate 32, and the first fixing plate 31 is opened with a second bolt hole 311 that matches the first bolt hole 212. Through the arrangement of the above structure, the support beam 2 i...

Embodiment 3

[0049] See Figure 1 to 8The mounting structure of a container building peripheral strobe provided in the first embodiment of the present invention is shown. The present embodiment further has further made the following as an improved technical solution based on the above embodiments: connection The strip 4 includes a connecting plate 41, a constraper 42 that is perpendicular to the connecting plate 41 and a second mounting plate 43 that is obliquely connected to the top of the connecting plate 41; there are several and in the second mounting plate 43; The first mounting hole 521 matches the second mounting hole 431. Through the arrangement of the above structure, the enclosure 5 is connected to the structural frame bolt, which is convenient for on-site construction, and later removable and re-restructure, saving construction costs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com