Foundation pile for building

A technology for construction and foundation piles, which is applied in construction, sheet pile walls, foundation structure engineering, etc., can solve the problems of pile heads being fragile, and achieve the effect of increasing lateral stability, increasing stability, and increasing load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

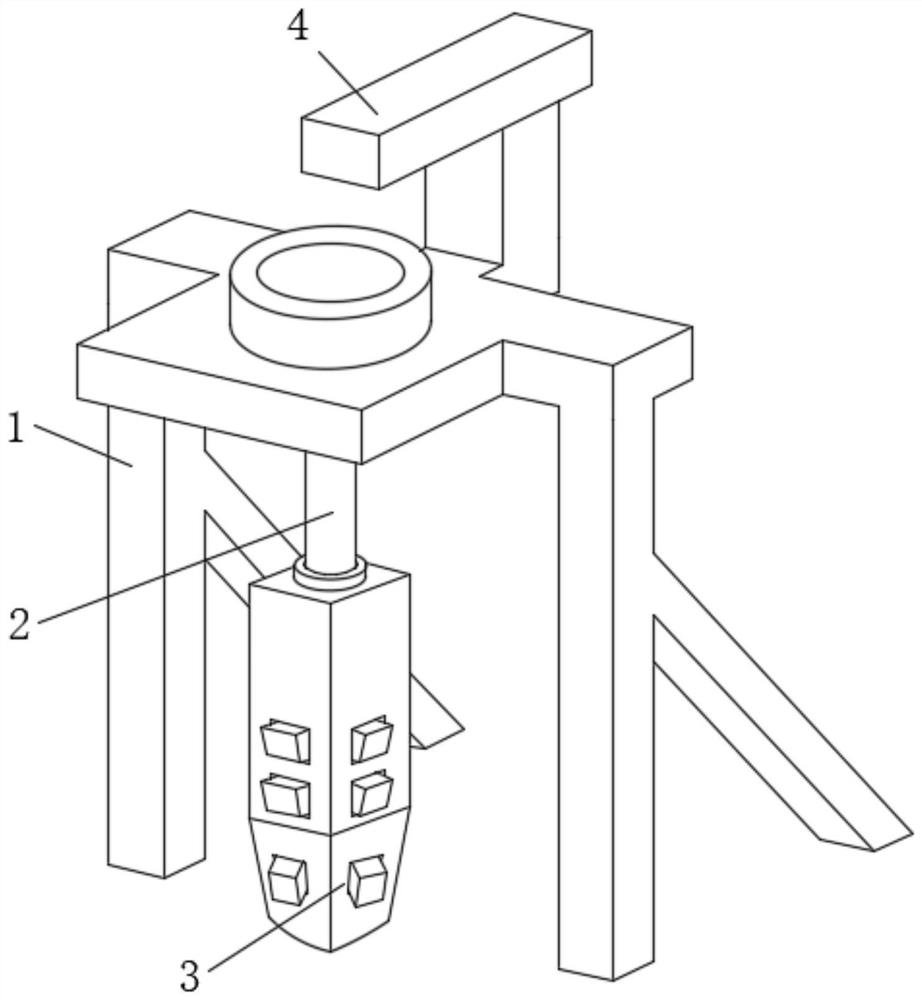

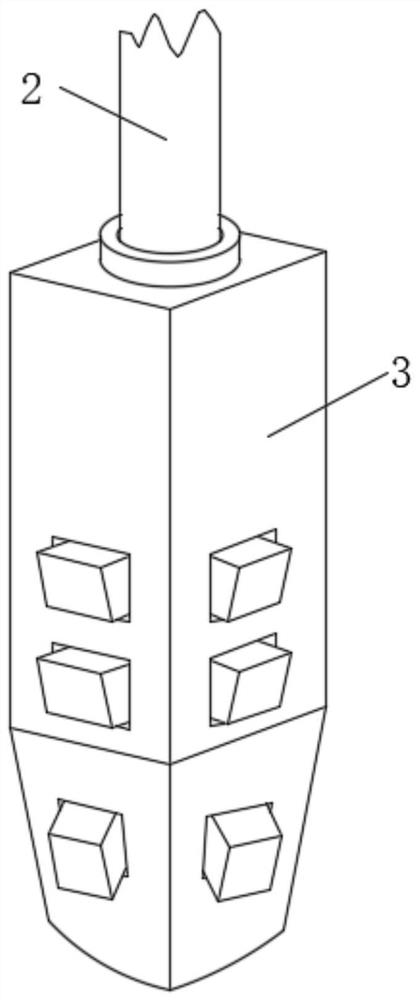

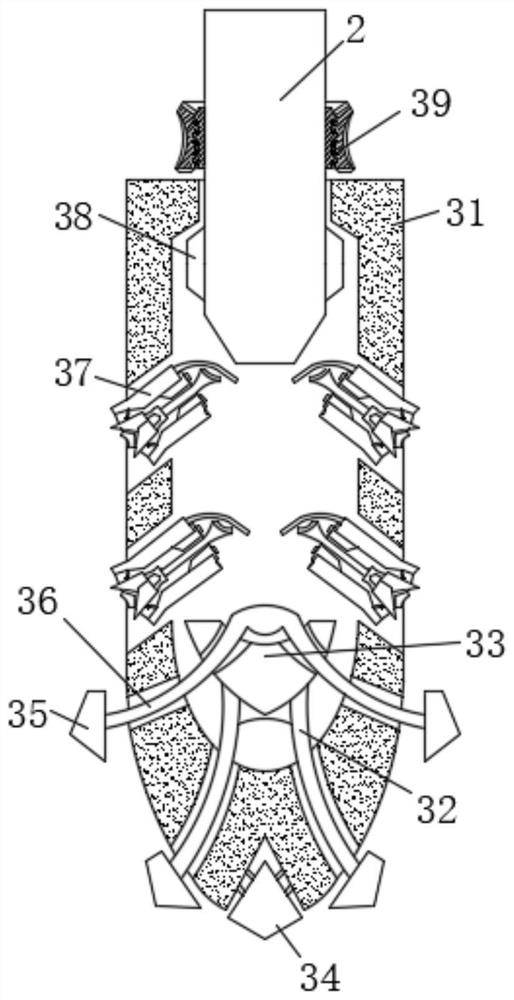

[0033] like Figure 1-4 As shown, the present invention provides a technical solution: a foundation pile for construction, including a pile driving frame 1, a tamper 4 is fixedly connected to the top of the pile driving frame 1, and a pile body is sleeved on the upper surface of the pile driving frame 1 2. The bottom of the pile body 2 is movably connected with a pile head device 3, and the pile head device 3 includes a shifting block 38 and a chuck device 39, and the outer surface of the bottom of the pile body 2 is sleeved with a pile head shell 31, The outer surface of the pile body 2 is fixedly connected with a chuck device 39 and a shifting block 38 respectively, and the shifting block 38 is arranged at the inner chamber of the pile head case 31 and is adapted thereto, and the opening of the pile head case 31 inner wall A lateral pressure device 37 is sleeved at the center of the pile, a protective block 34 is fixedly connected to the bottom of the pile head shell 31 , an...

Embodiment 2

[0037] like Figure 5-7 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: the side pressure device 37 includes a side pressure shell 371, and the outer surface of the side pressure shell 371 is sleeved on the outer surface of the pile head shell 31. At the opening, the top of the left side of the side pressure shell 371 is fixedly connected with a pressure plate 372, and the inner wall of the right side of the side pressure shell 371 is fixedly connected with an anti-seepage ring 374, and the inside of the anti-seepage ring 374 is sleeved with Pressing rod 373 , the top of the pressing rod 373 fits with the pressing plate 372 .

[0038] The bottom of the pressure rod 373 is fixedly connected with a bifurcated rod 375, and the end of the bifurcated rod 375 away from the pressure rod 373 is fixedly connected with a catch device 376, and the bottom of the inner wall of the side pressure shell 371 is fixedly connected with an anti-seepage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com