Module walking type multi-point pushing equipment for bridge pushing

A kind of jacking equipment and walking technology, applied in bridge construction, bridges, erection/assembly of bridges, etc., can solve the problems of affecting jacking, accelerated wear of rotating shaft, increased friction coefficient between rotating shaft and crawler, etc. , The effect of improving the degree of fit and reducing the coefficient of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] as attached figure 1 to attach Figure 5 Shown:

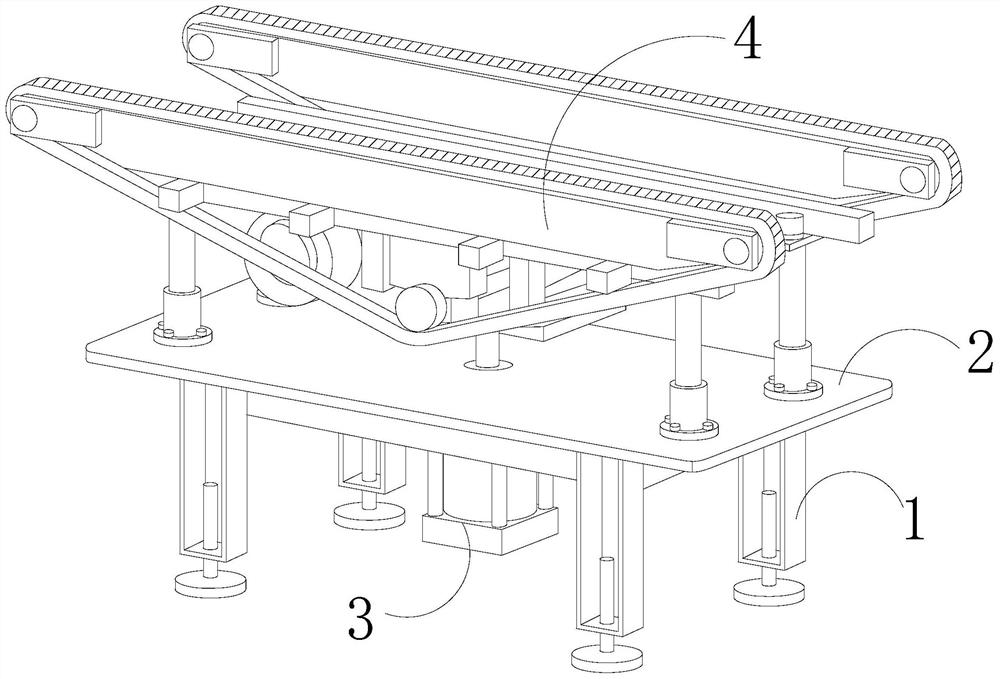

[0028] The present invention provides a modular walking multi-point pushing equipment for bridge pushing. Its structure includes a bracket 1, a support plate 2, a hydraulic cylinder 3, and a pushing device 4. The support plate 2 is horizontally fixed on the top of the support 1. , the hydraulic cylinder 3 is installed vertically at the center of the bottom of the support plate 2 , and the pushing device 4 is arranged on the top of the support plate 2 and cooperates with the hydraulic cylinder 3 movably.

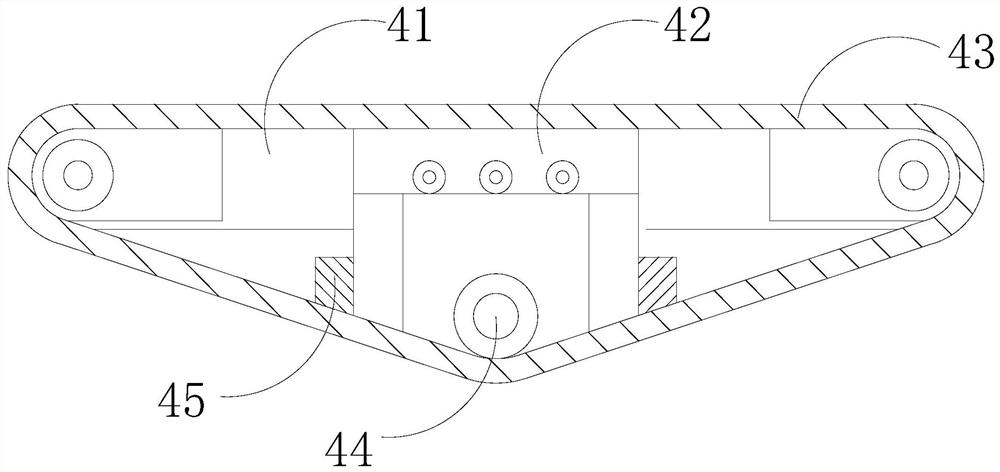

[0029] The pushing device 4 is provided with a matching plate 41, a motor 42, a crawler belt 43, a rotating shaft 44, and a clearing mechanism 45. The matching plate 41 is located above the pushing device 4, and the motor 42 is installed at the front center of the matching plate 41. , the rotating shaft 44 is movably matched with the middle and lower positions of the front of the motor 42 , the crawler belt 43 surroun...

Embodiment 2

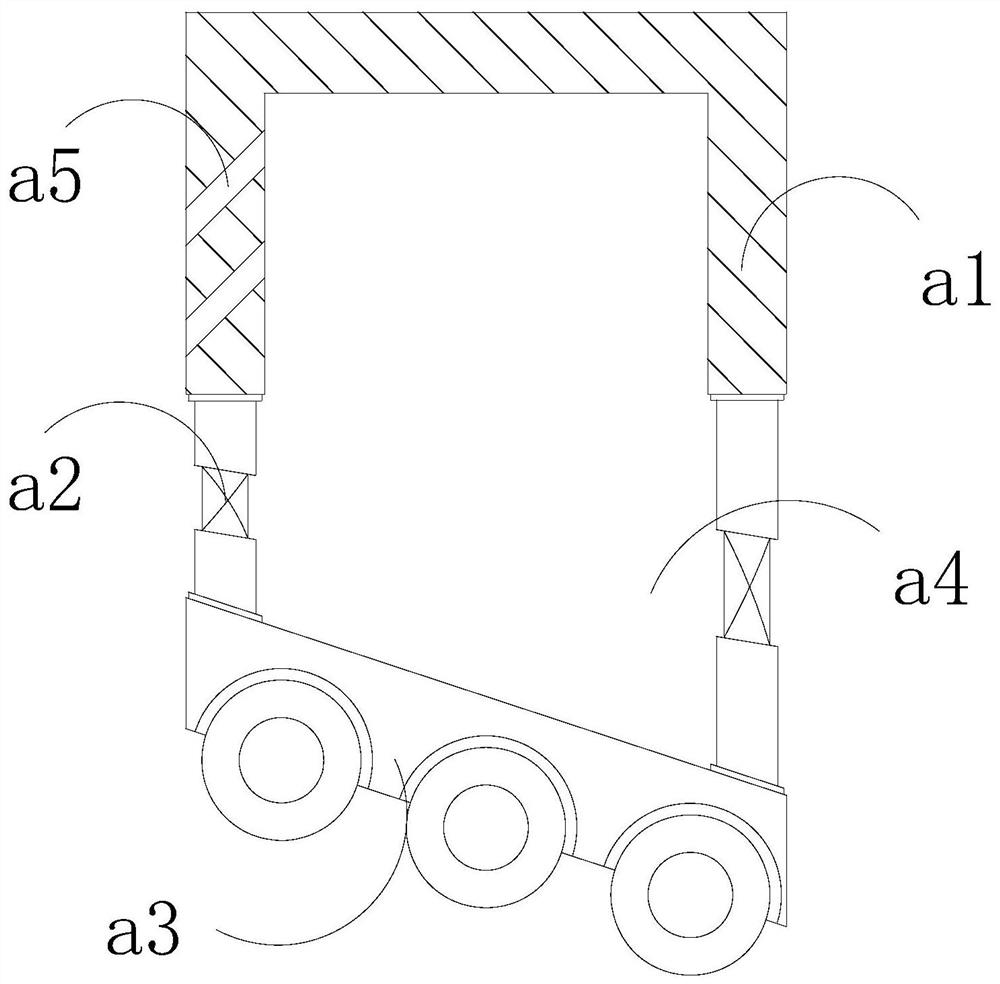

[0036] as attached Figure 6 to attach Figure 8 Shown:

[0037] Wherein, the opening s2 is provided with a supporting rod e1, an connecting shaft e2, and a diffusion ring e3, the supporting rod e1 is horizontally fixed on the inner wall of the bottom end of the opening s2, and the diffusion ring e3 is connected and installed in the center of the supporting rod e1 through the connecting shaft e2 position, the support rod e1 is in the shape of a flat plate, which is just set on the inner wall of the opening s2, which is beneficial to block the material and reduce the back suction force of the material from the airflow to enter along the opening s2, which is conducive to keeping the opening s2 unblocked and speeding up the airflow along the opening s2 The speed of diffusion.

[0038] Wherein, the diffusion ring e3 is provided with a drainage port r1, a push rod r2, and a clip r3, the drainage port r1 runs through between the outer wall and the interior of the diffusion ring e3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com