Dyeing process of polyester fabric

A fabric and polyester technology, which is applied in the dyeing process of polyester fabrics, can solve problems such as poor flame retardant effect, and achieve the effect of improving emulsion instability and excellent flame retardant performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

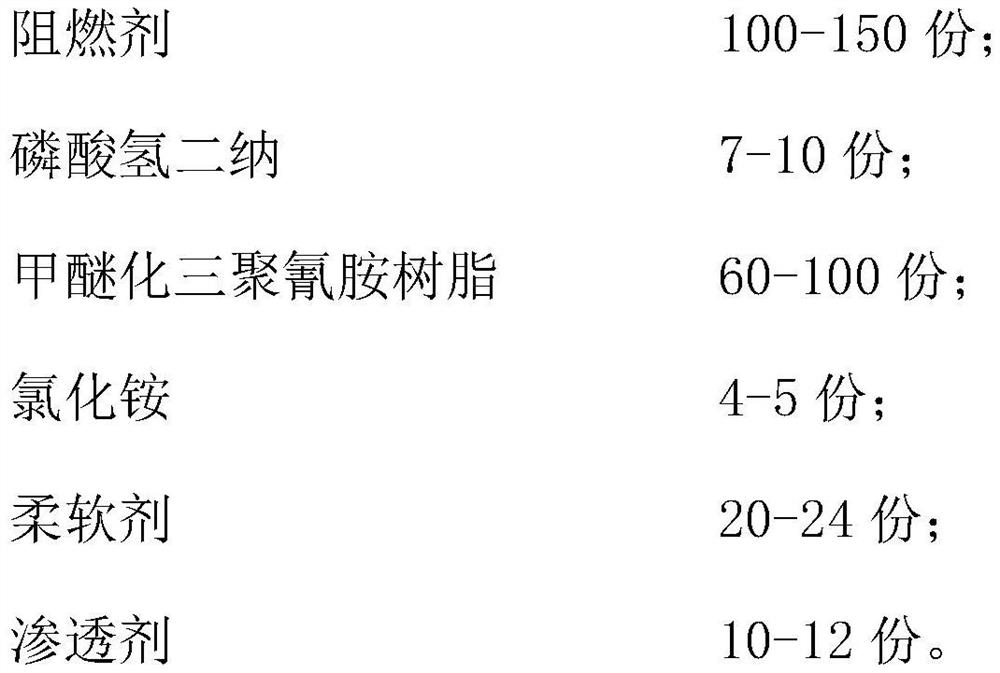

Method used

Image

Examples

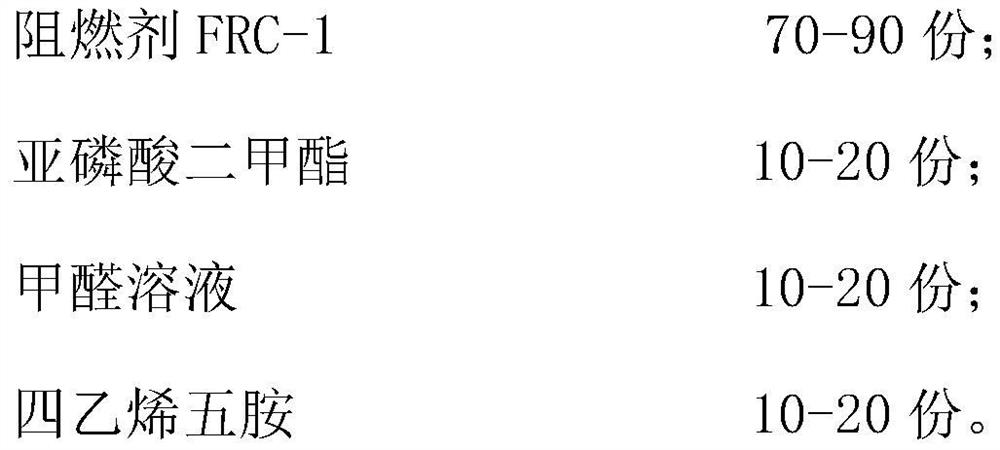

preparation example 1

[0050] A flame retardant, made of the following raw materials by weight: 70kg flame retardant FRC-1; 10kg dimethyl phosphite; 10kg formaldehyde solution; 10kg tetraethylenepentamine;

[0051] A preparation process of a flame retardant specifically comprises the following process steps:

[0052] Step 1, add tetraethylenepentamine into the reaction kettle in proportion, heat and stir the reaction kettle, control the temperature of the system in the reaction kettle to be constant at 35°C, control the stirring speed at 100r / min, add the formaldehyde solution dropwise in proportion Enter the reaction kettle, keep the system temperature in the reaction kettle constant at 35°C during the dropwise addition, and cool the system temperature in the reaction kettle to room temperature for 30 minutes after the dropwise addition is completed.

[0053] Step 2: Heat and stir the reactor, control the system temperature in the reactor to be constant at 35°C, control the stirring speed to 100r / m...

preparation example 2-5

[0055] The differences between the parts by weight of the raw materials and the process parameters of the preparation examples 2-5 and the preparation example 1 are listed in Table 2, and the rest are the same as the preparation example 1.

[0056] Parts by weight and process parameters of raw materials in table 2 preparation example 2-5 flame retardant

[0057]

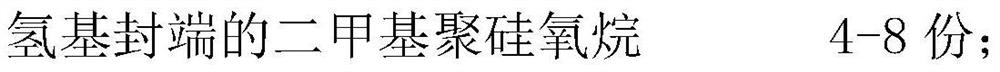

preparation example 6

[0059] A softener, made of the following raw materials in parts by weight: 4kg of hydrogen-terminated dimethyl polysiloxane, the molecular weight of which is about 3100; 8kg of glycidyl methacrylate; 3kg of diethylenetriamine; 5kg of iso propanol;

[0060] A kind of preparation technology of softening agent specifically comprises the following processing steps:

[0061] Step 1, add 0.1kg of chloroplatinic acid into 5kg of isopropanol, stir the isopropanol, control the stirring speed to 100r / min, and stir for 5min to obtain a mixed solution, put the mixed solution into a 50°C water bath for ultrasonic oscillation Treat in the container for 25min to obtain the catalyst solution.

[0062] Step 2, add 4kg of hydrogen-terminated dimethyl polysiloxane and 8kg of glycidyl methacrylate into the reactor in proportion, heat and stir the reactor, and control the stirring speed to 200r / min. After the internal system temperature reached 85°C, the catalyst solution was added into the reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com