Post-weld heat treatment method for high-temperature alloy

A post-weld heat treatment and high-temperature alloy technology, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve problems such as overaging, aging cracks, and inability to effectively eliminate welding residual stress, and achieve the effect of restoring mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

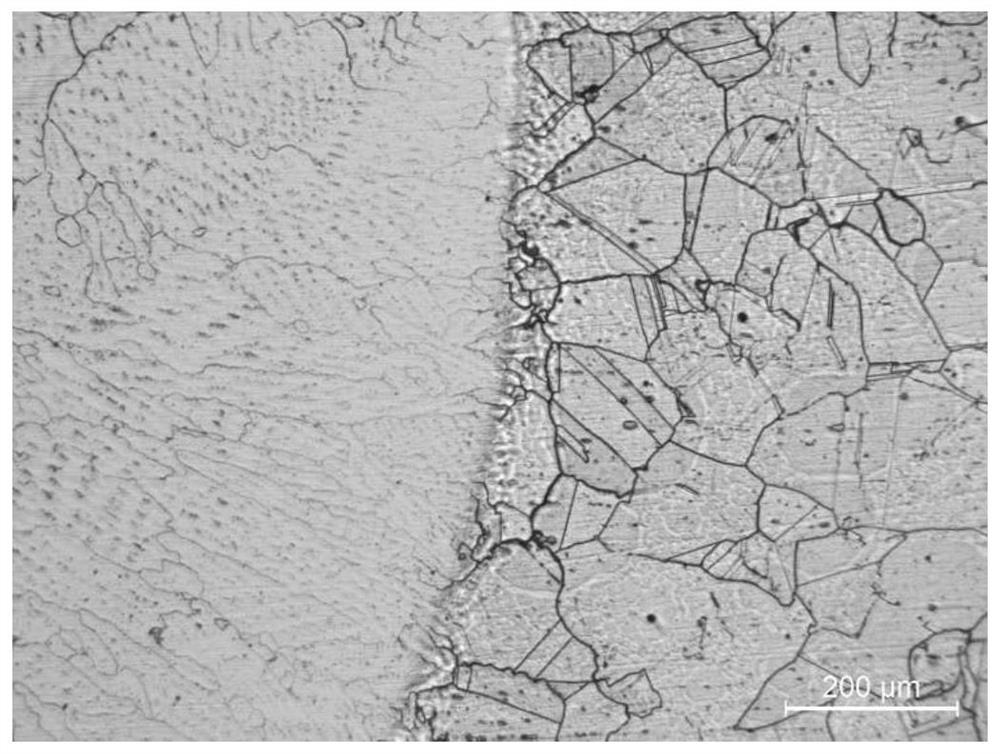

[0022] See Table 1 and figure 1 According to thermodynamic calculations, the recrystallization temperature of Inconel740H is 995°C, and the γ' phase precipitation temperature is 976°C. Post-weld heat treatment for Inconel740H welded joints: 1025°C / 1h low temperature solid solution + 800°C / 5h / air cooling aging treatment , no defects such as welding cracks, HAZ hardness is 290HV, base metal hardness is 295HV.

Embodiment 2

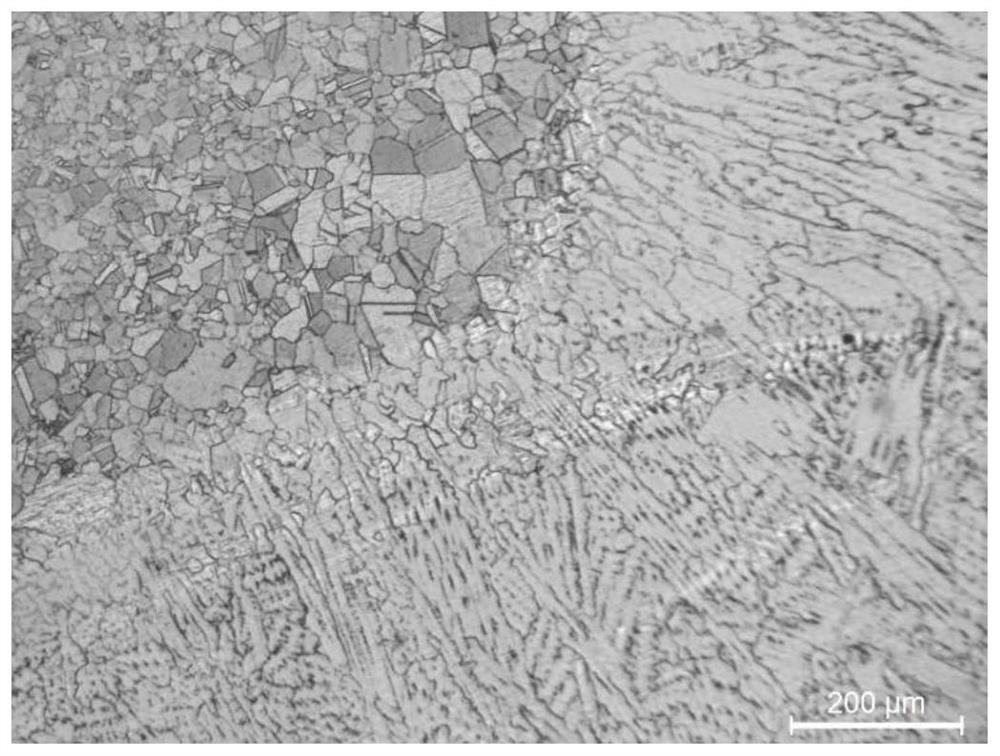

[0024] See Table 1 and figure 2 According to thermodynamic calculations, the recrystallization temperature of Haynes282 alloy is 988°C, and the γ' phase precipitation temperature is 989°C. Post-weld heat treatment for Haynes282 welded joints: 1010°C / 2h low temperature solid solution + 788°C / 8h / air cooling aging After treatment, no defects such as welding cracks occur, the hardness of the HAZ is 290HV, and the hardness of the base metal is 310HV.

[0025] Table 1 embodiment welding wire and base metal measured chemical composition (mass fraction %)

[0026] chemical composition C Fe Cr co Al Ti mn Mo Nb Si B Ni Inconel 740H 0.03 1.0 25.0 20.0 1.4 1.4 0.3 0.5 1.5 0.2 0.001 Remain Haynes 282 0.04 1.0 19.5 10.0 1.5 2.1 0.3 8.5 - 0.1 0.003 Remain

PUM

| Property | Measurement | Unit |

|---|---|---|

| recrystallization temperature | aaaaa | aaaaa |

| recrystallization temperature | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com