Blocky sludge drying system

A drying system and sludge technology, which is applied in dehydration/drying/concentrated sludge treatment, energy wastewater treatment, etc., can solve the problems of heavy manual work, health hazards of workers, and harm to workers' health. The work load is small, the effect of reducing dust to protect the environment and workers' health, and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

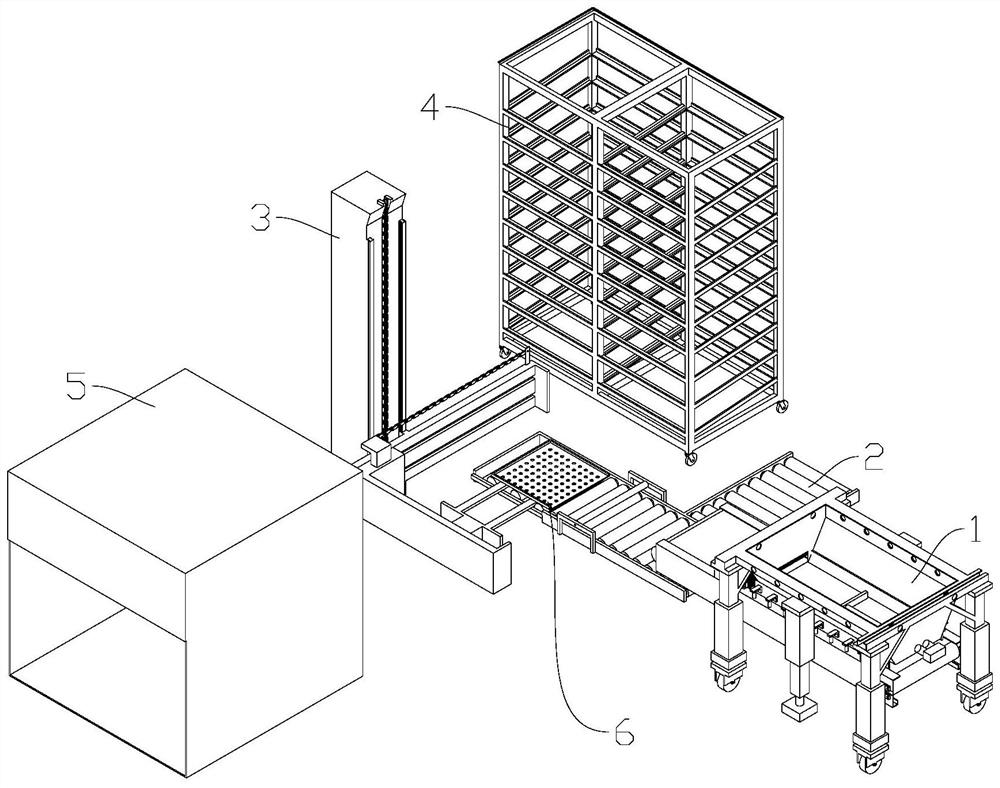

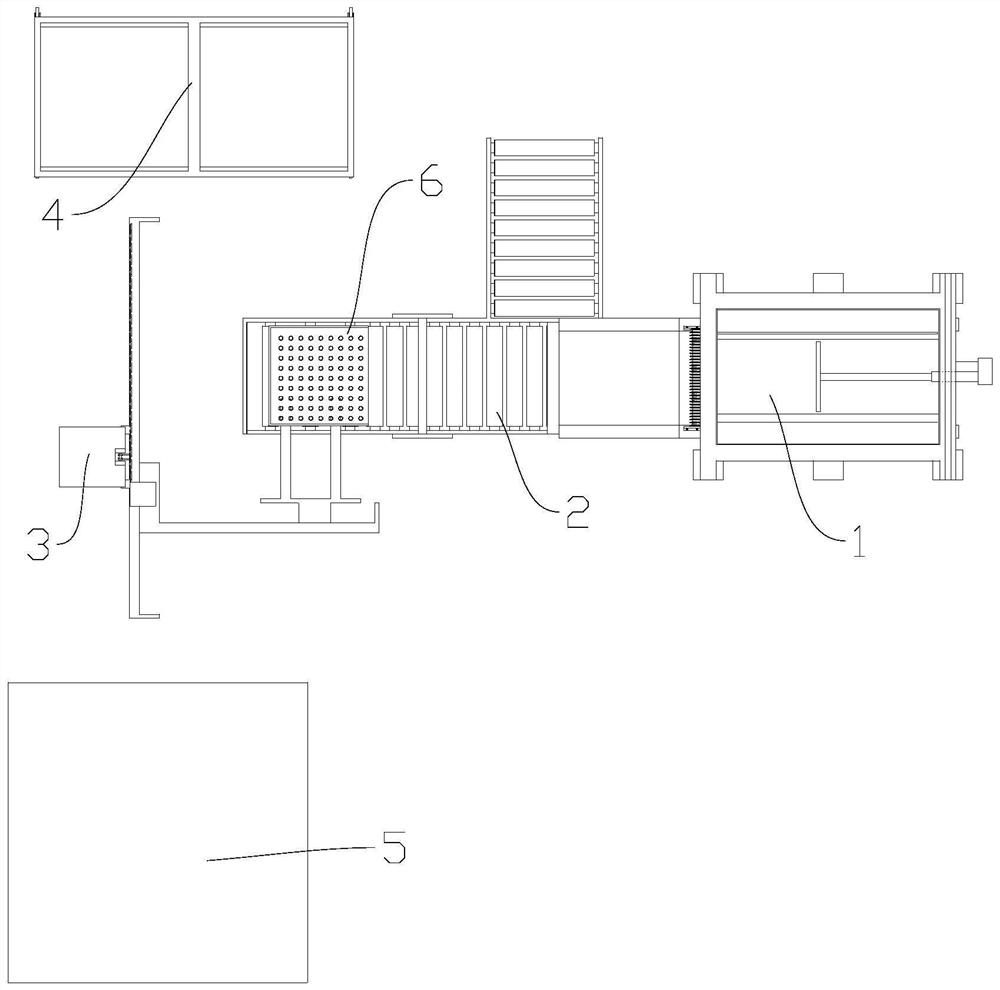

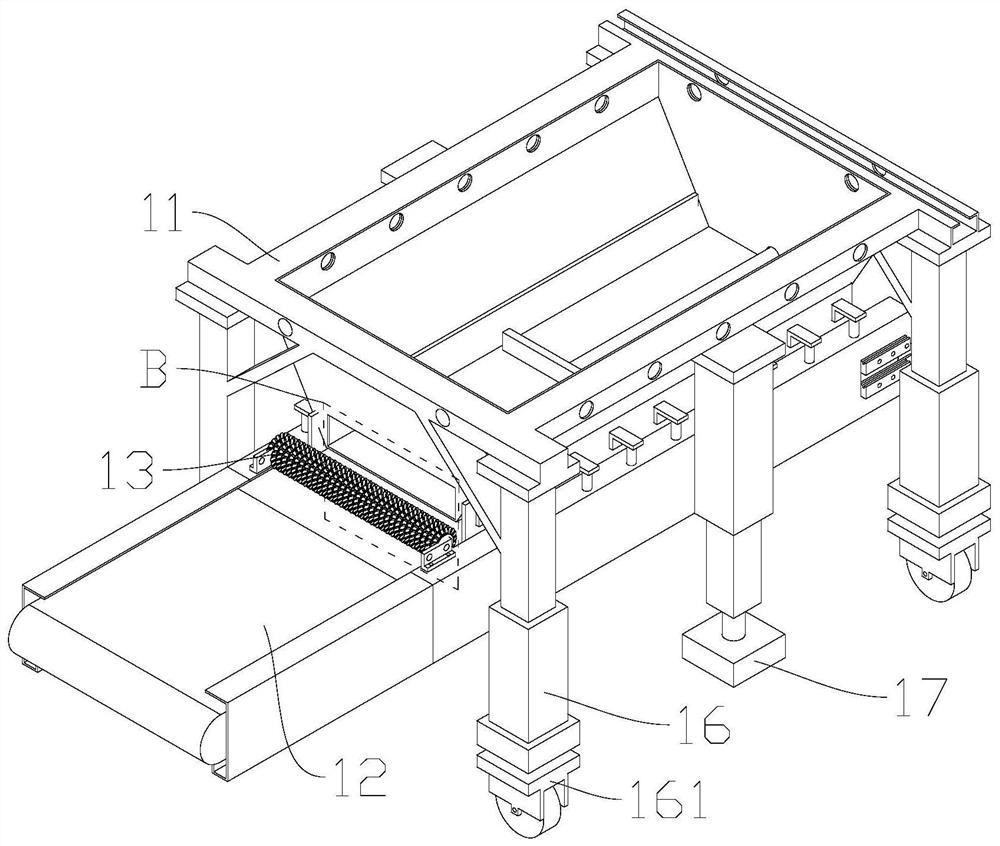

[0042] Example. The bulk sludge drying system is composed of Figure 1-11 As shown, it includes a receiving device 1, a conveying platform 2 for transporting sludge arranged under the front end of the receiving device 1, a tray 6 arranged on the conveying platform 2 for carrying sludge, and arranged in front of the conveying platform 2 The three-dimensional transfer device 3 that can drive the tray 6 to move three-dimensionally, the two sides of the three-dimensional transfer device 3 and the conveying platform 2 are respectively provided with a drying rack 4 and a discharge box 5; the receiving device 1 includes a receiving rack 11, The feeding crawler belt 12 that is located at the material receiving rack 11 below, is located at the blade roller 13 that is positioned at the material receiving rac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com