A solvent selection method for preparing carbon materials

A carbon material and solvent technology, which is applied in the field of solvent selection for the preparation of carbon materials, can solve the problems of inability to quickly and accurately select high-quality solvents and less solvents, and achieve the effect of unique shape, simple method and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Choice of one-component solvent systems:

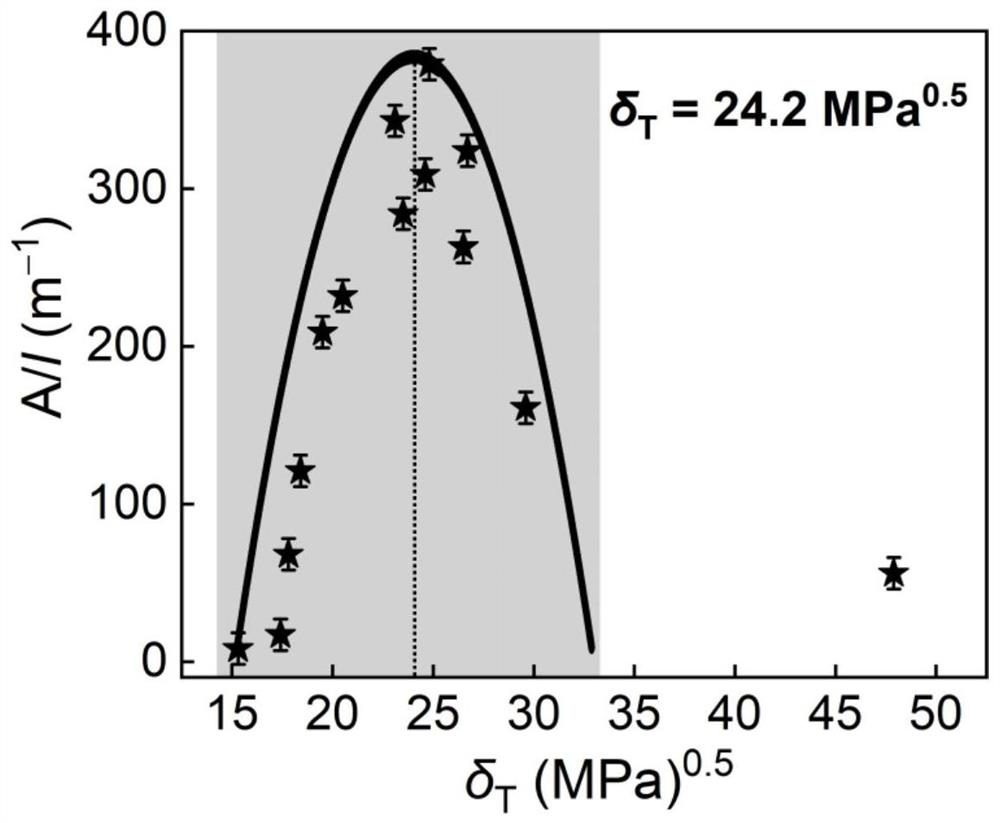

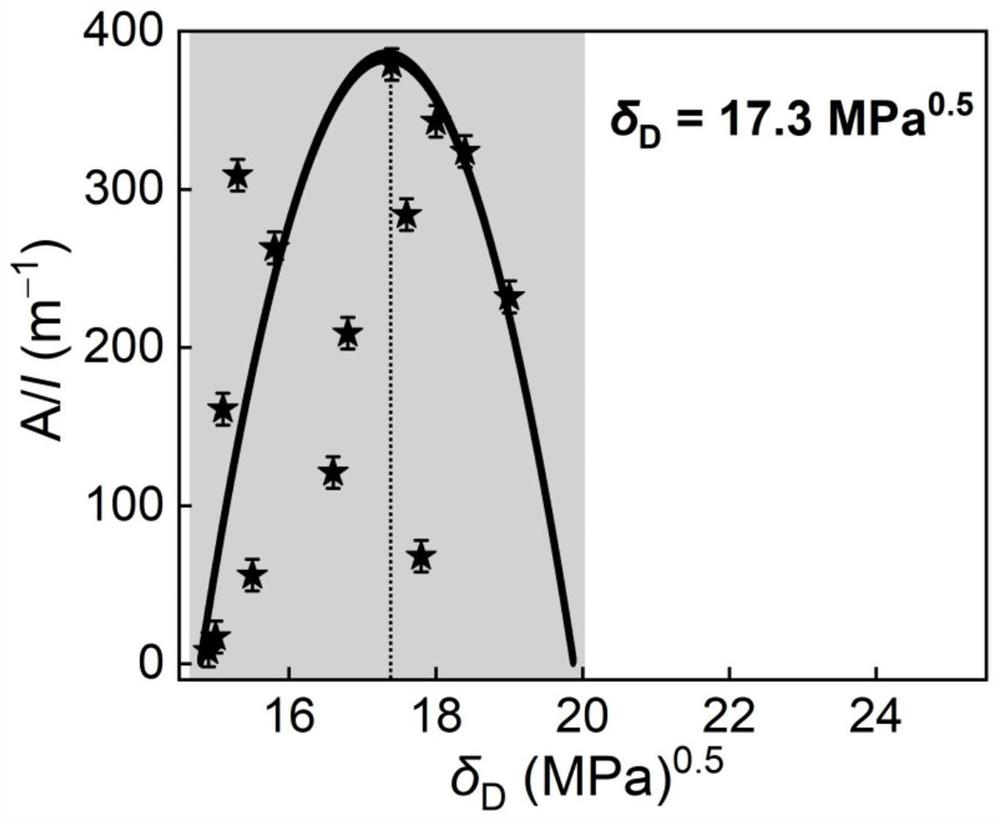

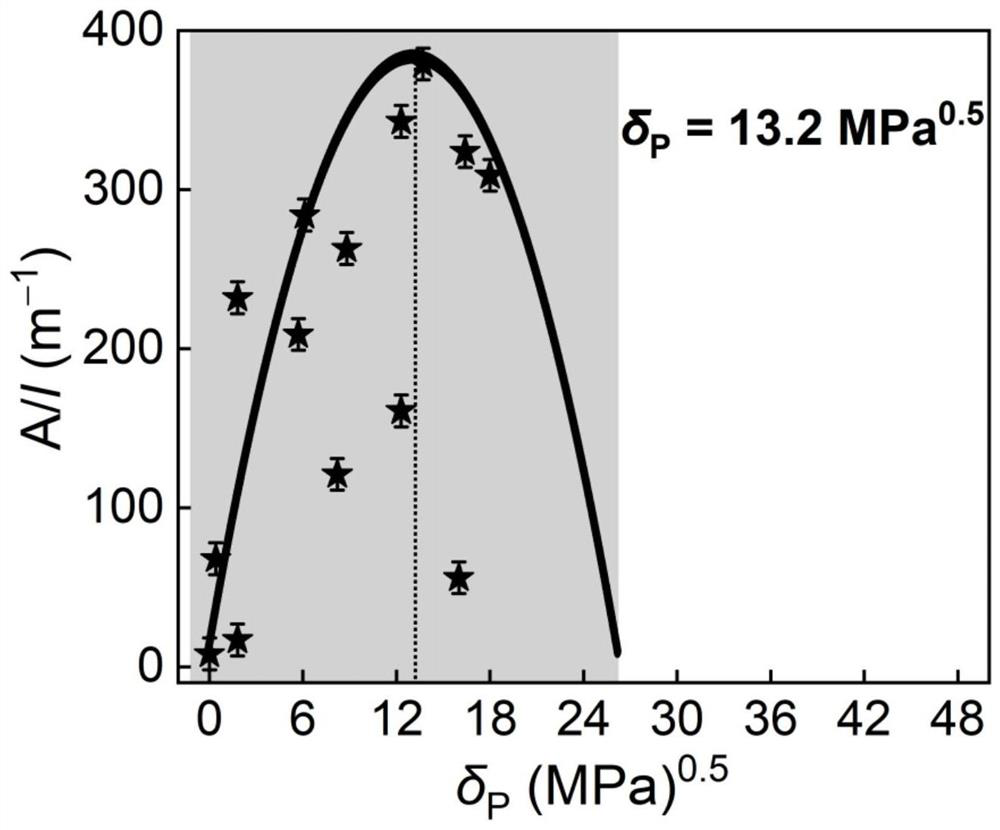

[0042] First, the Hansen solubility parameter of the polyimide precursor was determined. Take 12 parts of polyimide of equal mass (0.1 g per part) and uniformly disperse them in 12 parts (10 ml per part) of different solvents by ultrasonic wave respectively to obtain 12 kinds of dispersion liquids. Solvents include N,N-dimethylformamide, N-methylpyrrolidone, dimethylsulfoxide, acetonitrile, ethanol, isopropanol, mesitylene, methanol, dioxane, n-hexane, dichloroethane and in the tetrahydrofuran system (the δ of the 12 one-component solvents used T,溶剂 ,δ D,溶剂 ,δ P,溶剂 and δ H,溶剂 value, which can be obtained from a look-up table in the Hansen Solubility Parameters: A User's Handbook). Subsequently, 12 parts of the dispersion were centrifuged, and 12 parts of the supernatant were collected as samples to be tested. The maximum absorbance (A) of 12 solutions at a wavelength of 200 nm was tested respectively by ultraviolet absorp...

Embodiment 2

[0057] Two-component solvent system: first based on formula Five candidate two-component solvents were calculated (mesitylene / N,N-dimethylformamide, dioxane / N,N-dimethylformamide, methanol / N-methylpyrrolidone, isopropanol / Hansen solubility parameter (δ) of acetonitrile, N-methylpyrrolidone / dimethyl sulfoxide) T,混合溶剂 ,δ D,混合溶剂 ,δ P,混合溶剂 and δ H,混合溶剂 value), and the calculation results are shown in Table 2.

[0058] Table 2 Compatibility analysis between different candidate two-component solvent systems and polyimide

[0059]

[0060]

[0061] The specific calculation process takes mesitylene / N,N-dimethylformamide mixed solvent as an example. When mesitylene:N,N-dimethylformamide=50:50, mesitylene / N,N- Dimethylformamide mixed solvent:

[0062]

[0063]

[0064]

[0065]

[0066] According to the Hansen solubility parameter of polyimide determined in Example 1:

[0067] δ T,聚酰亚胺 =24.2(Mpa) 0.5 ,

[0068] δ D,聚酰亚胺 =17.3(Mpa) 0.5 ,

[0069] δ P,聚酰亚...

Embodiment 3

[0080] Multicomponent solvent systems: first based on the formula Calculate 5 candidate 3-component solvents (mesitylene / N-methylpyrrolidone / dimethylsulfoxide, N-methylpyrrolidone / N,N-dimethylformamide / dimethylsulfoxide, dioxane Cyclo / N,N-dimethylformamide / methanol, mesitylene / N-methylpyrrolidone / N,N-dimethylformamide, N-methylpyrrolidone / dimethylsulfoxide / methanol) Sen solubility parameter (δ T,混合溶剂 ,δ D,混合溶剂 ,δ P,混合溶剂 and δ H,混合溶剂 value), and the calculation results are shown in Table 3.

[0081] Table 3 Compatibility analysis between different candidate three-component solvent systems and polyimide.

[0082]

[0083]

[0084] The specific calculation process takes mesitylene / N-methylpyrrolidone / dimethyl sulfoxide mixed solvent as an example. When mesitylene:N-methylpyrrolidone:dimethylsulfoxide=1:2:7:

[0085]

[0086]

[0087]

[0088]

[0089] According to the Hansen solubility parameter of the polyimide precursor determined in Example 1:

[0090...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com