Belt breakage prevention chain belt breakage grabbing conveyor for implementing belt breakage prevention chain belt breakage grabbing method

A broken belt and chain belt technology, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of large space occupation, difficult installation, large space occupied by belt conveyor overlaps, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

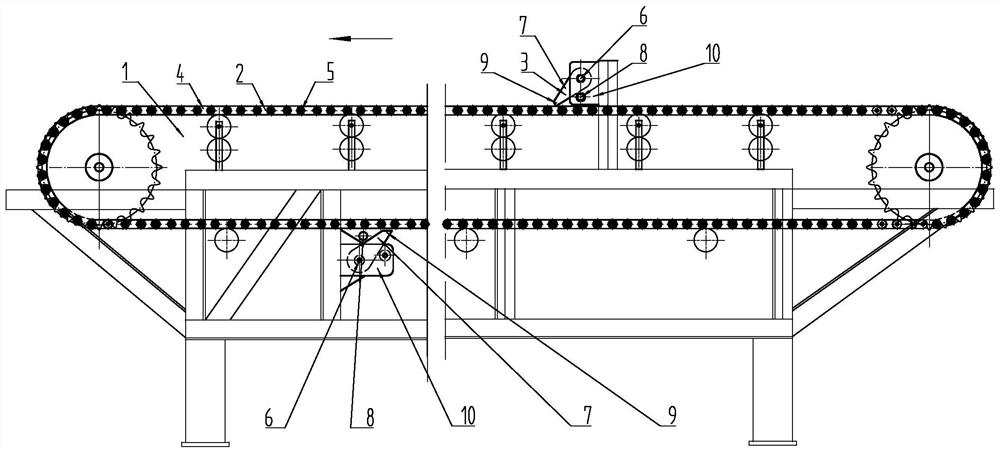

[0180] Such as figure 1 As shown, the anti-breakage belt grab chain belt broken belt conveyor 1 includes a transport chain belt 2 and a chain belt breaker 3, and the transport chain belt 2 includes a conveyor belt 4 and a conveyor belt chain 5, and the conveyor belt chain 5 is arranged on the conveyor belt 4 On both sides, the chain belt breaker 3 includes a belt breaker shaft 6 and a belt breaker 7, the belt breaker 7 is movably buckled with the belt breaker shaft 6, and the belt breaker 7 includes a belt stopper The tooth reversing part 8 and the belt breaker tooth 9 are blocked and the belt tooth reversing part 8 is prevented from catching the belt breaker tooth 9 from reverse rotation. The device bracket 10, the chain belt breaking device 3 is arranged on the chain belt breaking device support 10, when the belt breaking device 7 is movably buckled with the belt breaking device shaft 6 and the belt tooth reversing part 8 is used to stop When grabbing the belt device tooth ...

Embodiment 2

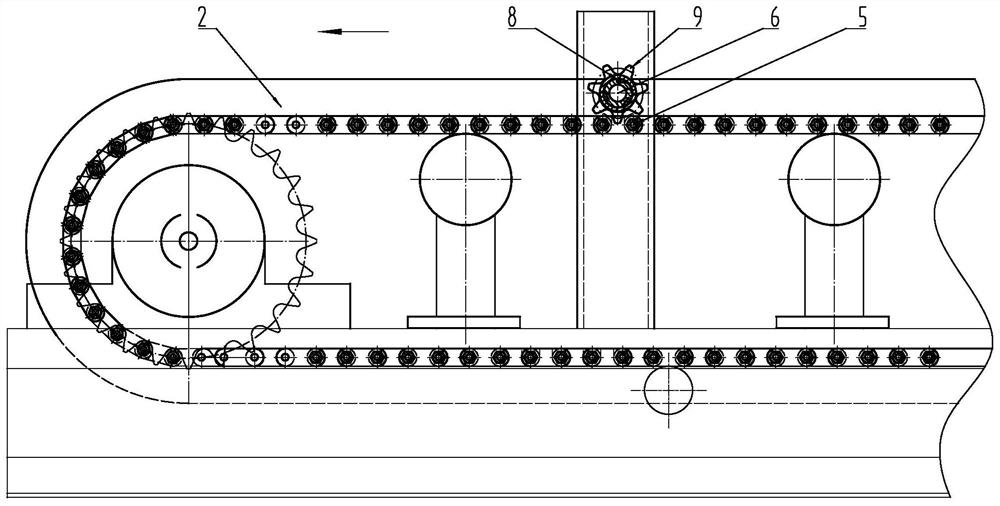

[0188] Such as figure 2 As shown, when using the grabber tooth 9 to mesh with the conveyor belt chain 5, the catcher tooth reversing member 8 is set between the grabber shaft 6 and the grabber tooth 9, and the conveyor chain belt 2. When transporting materials in the forward direction, the conveyor belt chain 5 drives the belt catcher teeth 9 to rotate around the belt breaker shaft 6, so that the conveyor chain belt 2 runs smoothly in the forward direction. Tooth reversing part 8 prevents from catching and breaking belt device tooth 9 and moves reversely around catching and breaking belt device shaft 6, and grabs and breaks belt device tooth 9 and prevents conveyor belt chain 5 from running in reverse.

[0189] Others are with embodiment 1.

Embodiment 3

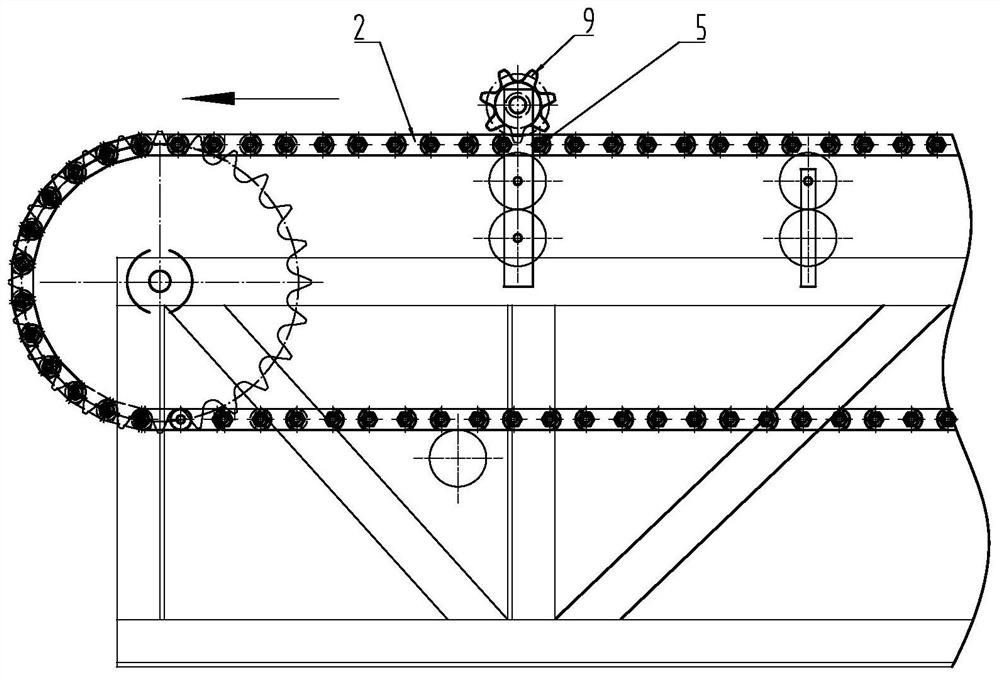

[0191] Such as image 3 As shown, when using the catcher tooth 9 to mesh with the conveyor belt chain 5, the catcher tooth 9 rotates around the grabber shaft 6, and when the conveyor chain belt 2 is forwardly running and feeding, the grabber Teeth 9 buckle the conveyor belt chain 5 and rotate, and when the conveyor chain belt 2 breaks, the belt device teeth 9 are caught to stop the conveyor belt chain 5 from coming off and swinging.

[0192] Others are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com