A screen printing device and method for kitchen electric glass surface

A screen printing device and glass surface technology, applied in screen printing machines, printing devices, printing, etc., can solve the problems of uneven distribution, inconsistent pattern or frosted pattern, etc., achieve good sealing effect, increase area, The effect of ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

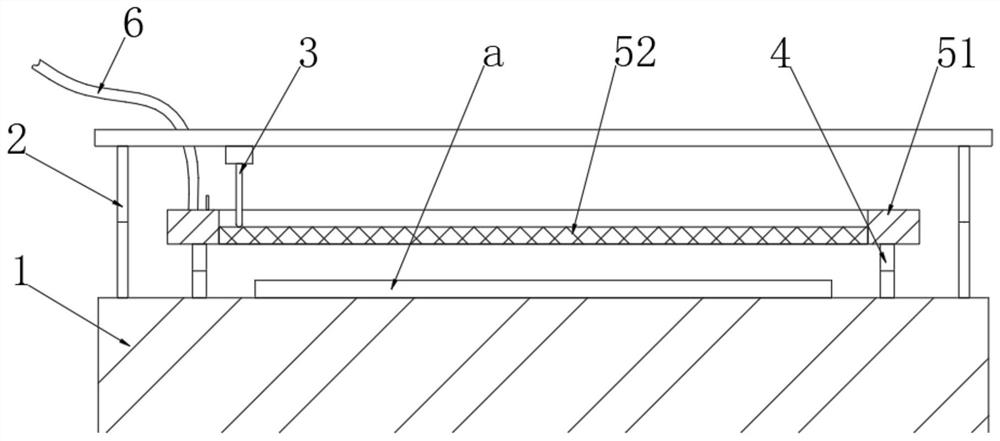

[0046] see figure 1 , a in the figure represents the kitchen electric glass to be printed, a screen printing device and method for the kitchen electric glass surface, including a printing table 1, the upper end of the printing table 1 is fixedly connected with a support frame 2 with an electric push rod, and the support frame 2 is connected with a scraper 3 through an electric sliding table, and the upper end of the printing table 1 is fixedly connected with a plurality of cylinders 4, and the upper end of the cylinder 4 is fixedly connected with a frame 51, and the inside of the frame 51 is fixedly connected with a screen plate 52, and the lower end of the scraper 3 is connected with the The silk screen panel 52 matches.

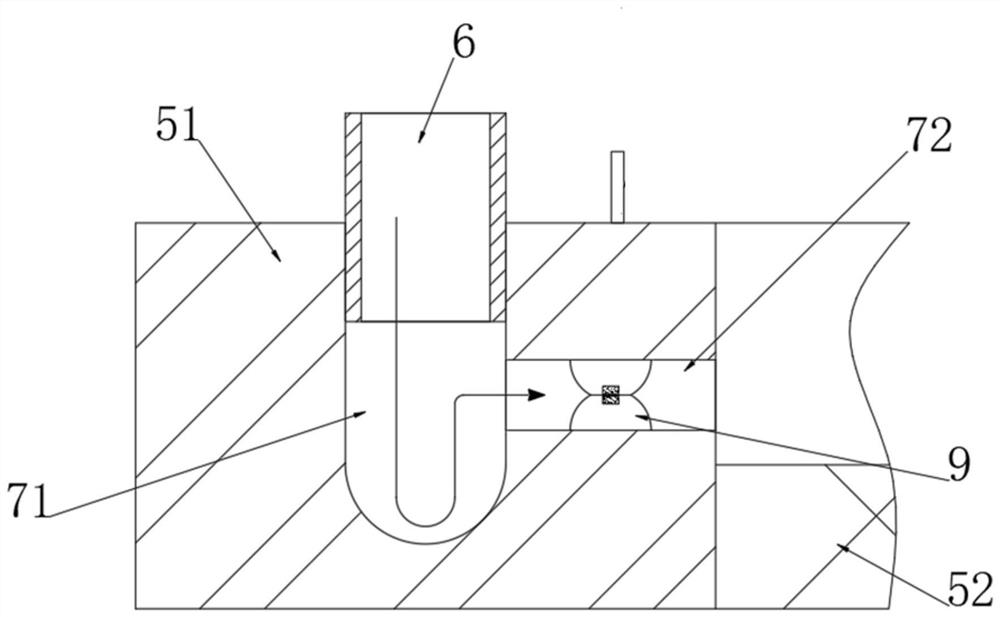

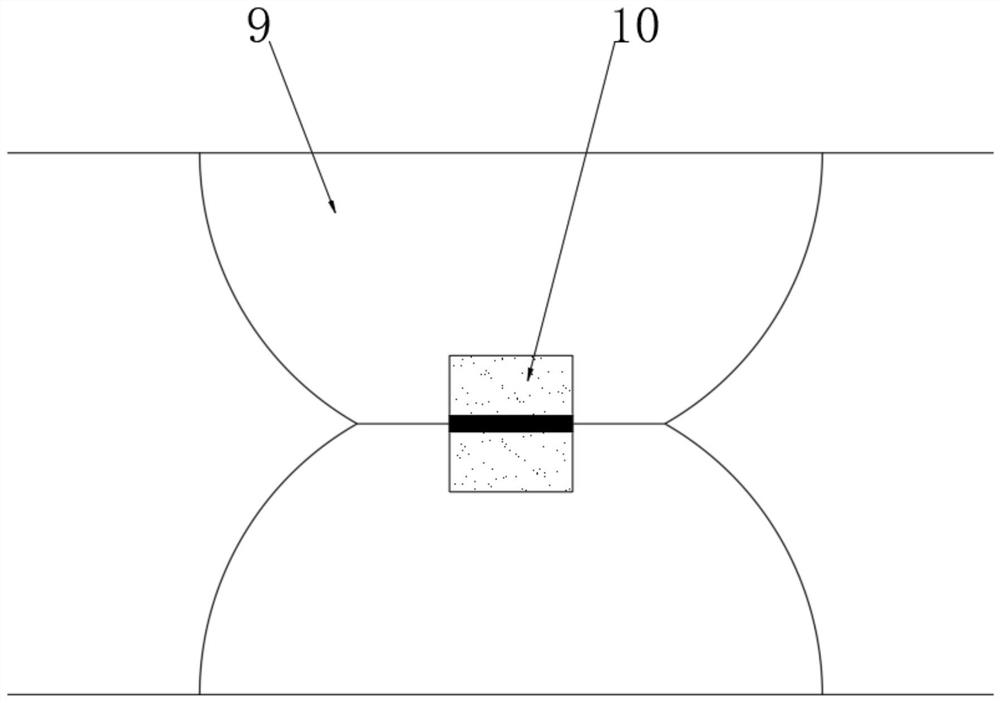

[0047] see Figure 2-3 , a T-shaped hole is dug in the frame 51, and the upper end of the T-shaped hole is fixedly connected with the feed pipe 6. The T-shaped hole includes a longitudinal groove 71 and a transverse groove 72 communicating with the longitu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com