Two-way stretching equipment for PTFE ultra-fine filtering membrane production

A technology of biaxial stretching and fine filtration, used in thin material processing, flat products, other household appliances, etc., can solve the problems of wasting manpower, high temperature of the expander chain, unqualified products, etc., and achieve the effect of improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

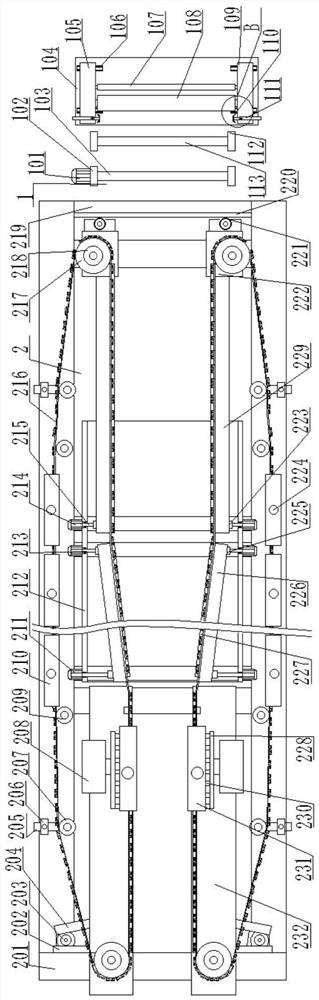

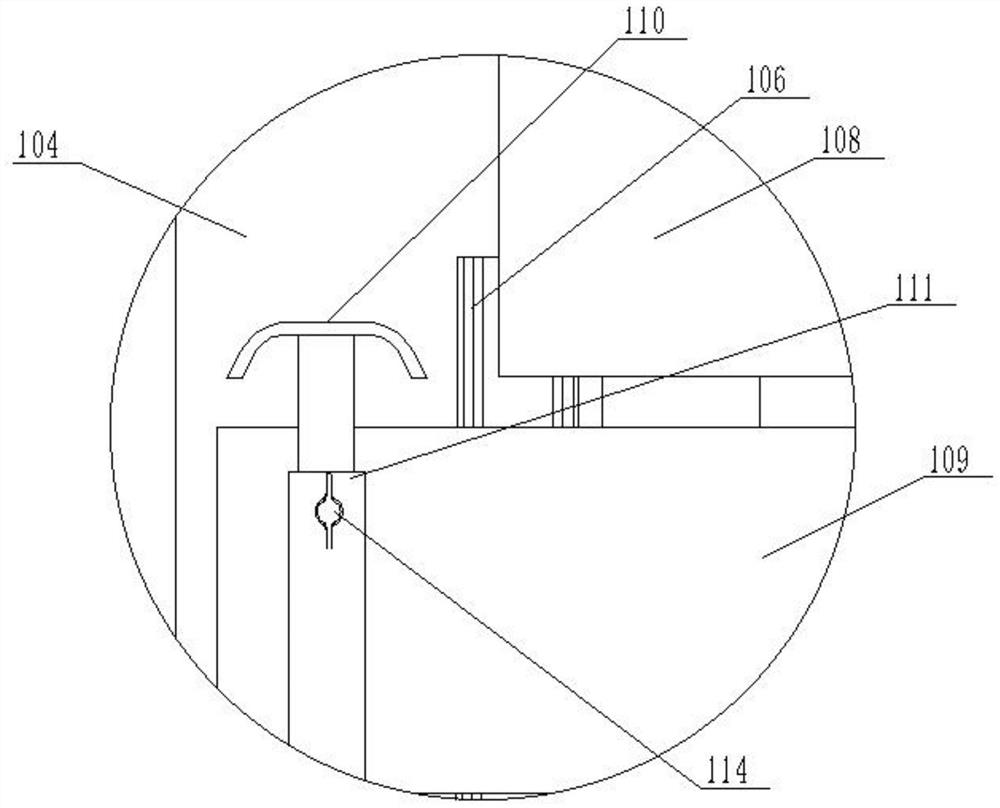

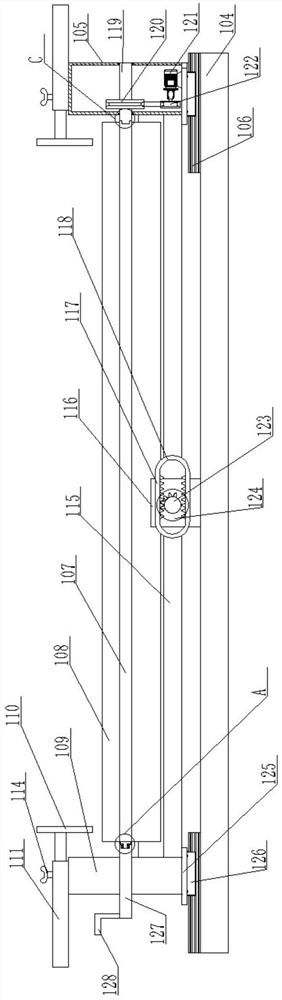

[0028] The specific implementation manners of the present invention will be described in further detail below with reference to the accompanying drawings.

[0029] Such as Figures 1 to 11 Shown, the present invention is the bidirectional stretching equipment that PTFE superfine filter membrane is produced, comprise expander 2 and be arranged on the winding mechanism 1 of its discharge end, expander 2 comprises frame and oven 212, is provided with a The conveyor chain 216 that clamps the both sides of the film and passes through the oven 212 is characterized in that: the return end of the conveyor chain 216 is outside the oven 212, and the outside of the return end of the conveyor chain 216 is provided with a multi-stage cooling box 210, and each section of the cooling box 210 Both are connected with suction pipe 224, the suction pipe 224 is connected with cooling fan 246, the outside of the process end of the conveyor chain 216 at the front end of the oven 212 is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com