Mold taking manipulator for injection molding

A technology of manipulators and support seats, which is applied in the field of injection molding manipulators, can solve problems such as mold burns, easy clamping inaccuracies, and injection molding machine failures, and achieve the effect of accelerating cooling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

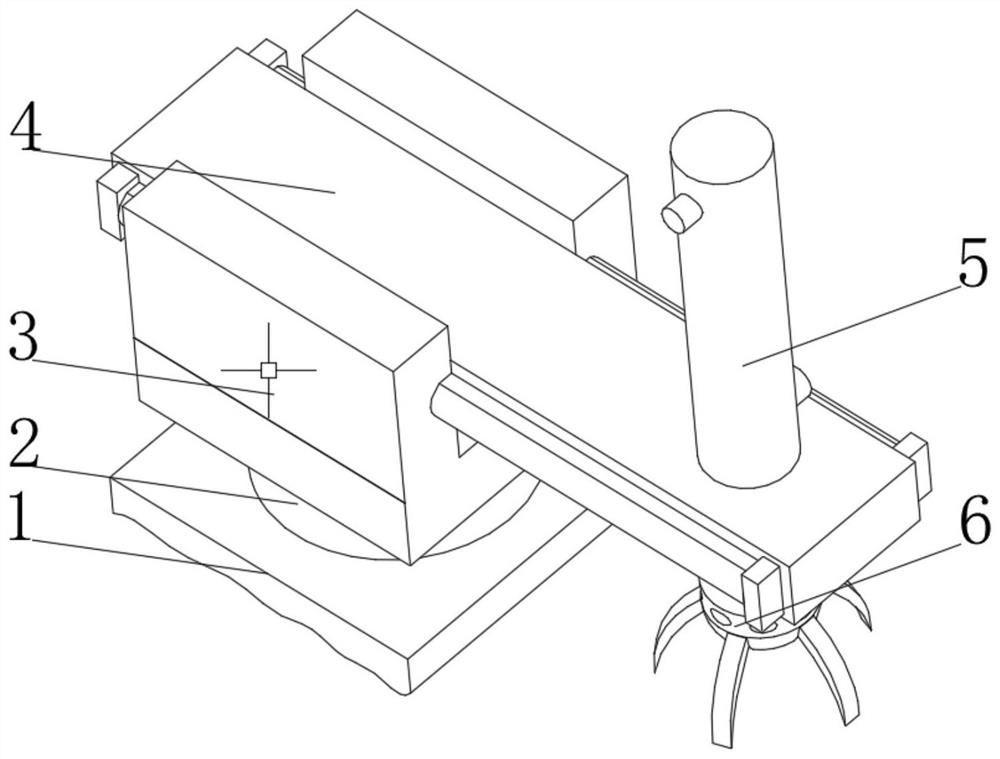

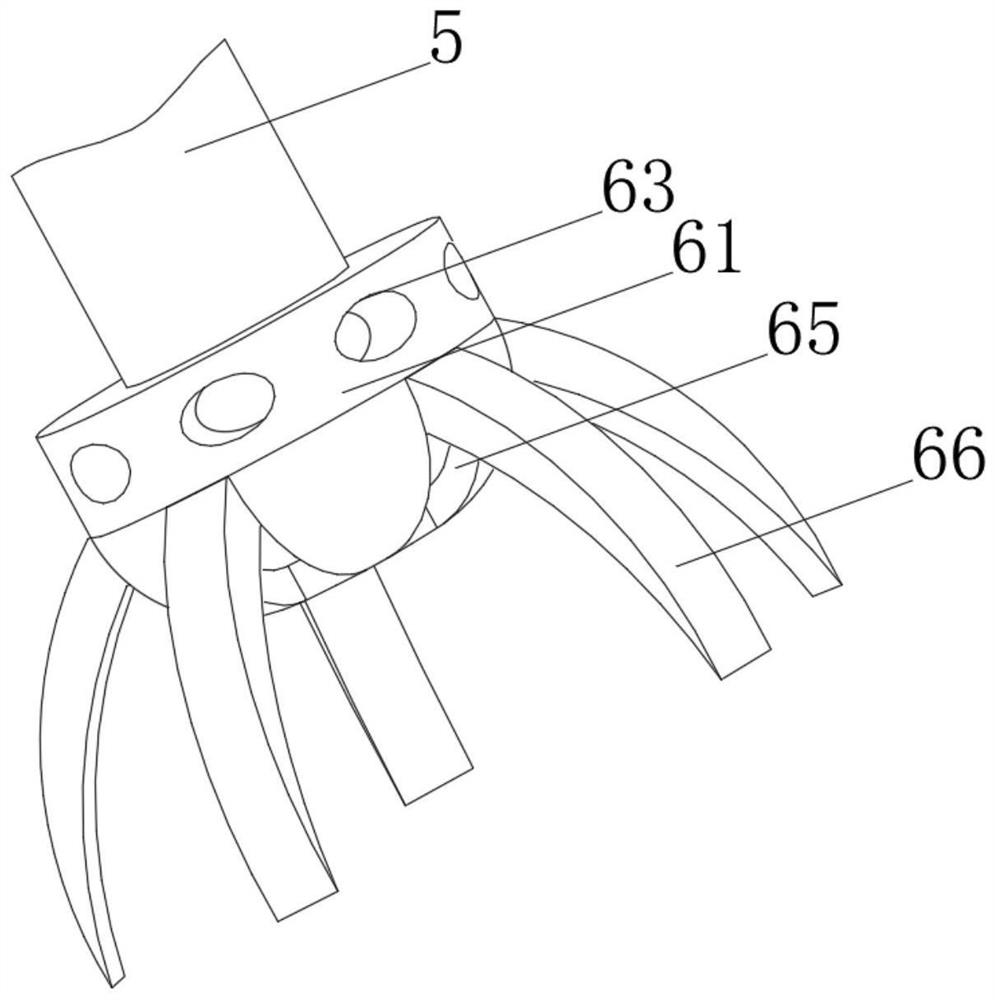

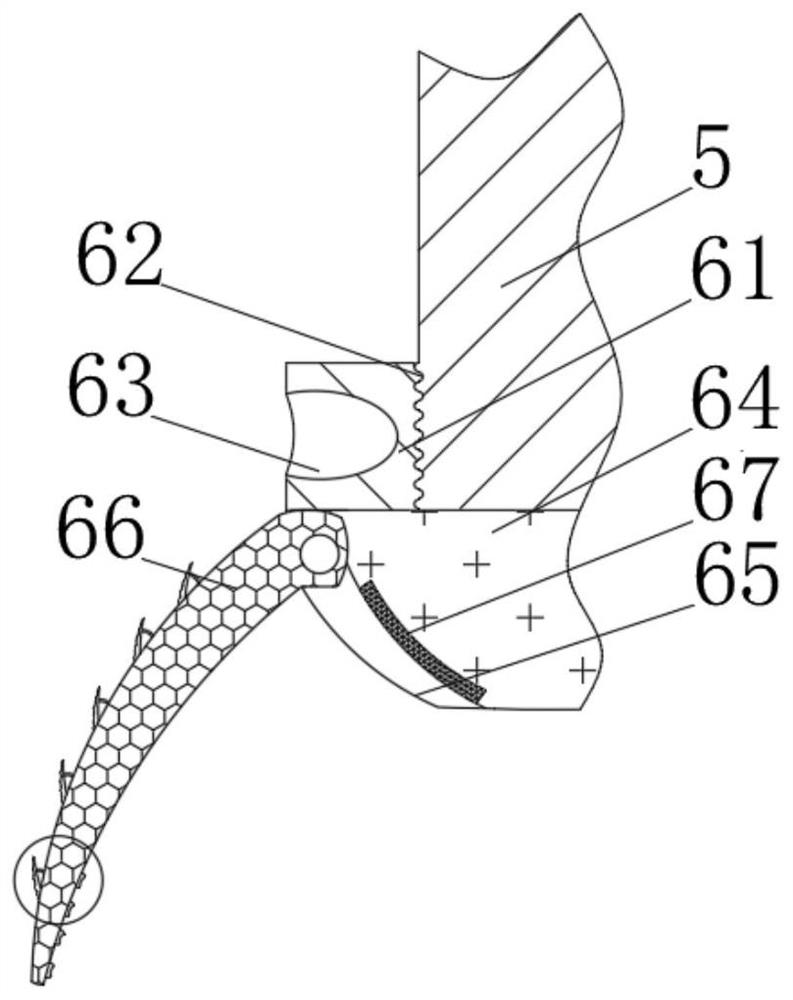

[0035] see Figure 1-4 , the present invention provides a technical solution: an injection mold taking manipulator, comprising a support base 1, the top of the support base 1 is rotatably connected to a rotation shaft 2, and the end of the rotation shaft 2 away from the support base 1 is fixedly connected to a fixed slider 3, The side of the inner wall of the fixed slider 3 is connected with a moving rod 4 through a motor, and the top of the end of the moving rod 4 away from the fixed slider 3 is provided with a pneumatic lifting device 5, and one end of the pneumatic lifting device 5 runs through the moving rod 4 and is threaded with a mold taking robot 6 The model taking manipulator 6 includes a connection block 61, the top of the connection block 61 is provided with a threaded hole 62, the side of the connection block 61 is provided with a lock groove 63, the bottom of the connection block 61 is fixedly connected with a manipulator 64, and the side of the manipulator 64 is p...

Embodiment 2

[0038] see Figure 3-6, the present invention provides a technical solution on the basis of Embodiment 1: an injection molding manipulator, the inner diameter gripping device 665 includes a moving support rod a1, one end of the moving support rod a1 is rotatably connected to the installation and fixing groove 663, and the moving support One side of the rod a1 is rotatably connected to an arc-shaped connecting rod a2 through a rotating seat, and the end of the arc-shaped connecting rod a2 away from the moving pole a1 is fixedly connected to a rotating plate a3, and both ends of the rotating plate a3 are fixedly connected to the first airbag a4 , the bottom of the rotating plate a3 is rotatably connected to the support rod a5 through the rotating seat, the end of the first air bag a4 and the support rod a5 away from the rotating plate a3 is fixedly connected to the fixed plate a6, and the end of the rotating plate a3 away from the arc-shaped connecting rod a2 is set There is an ...

Embodiment 3

[0041] see Figure 3-7 , the present invention provides a technical solution on the basis of Embodiment 1: an injection molding manipulator, the outer diameter gripping device 666 includes a placing plate b1, and one side of the placing plate b1 is respectively provided with a vent hole b2 and a chute b3, the side of the inner wall of the chute b3 is slidably connected with the fixed block b4, one end of the fixed block b4 is fixedly connected with the third airbag b5, and the end of the third airbag b5 away from the fixed block b4 is fixedly connected with the outer diameter clamping shell b6, the fixed block The material on the side of b4 away from the third airbag b5 is a material with elasticity and heat resistance;

[0042] When in use, when the size of the injection molded part is relatively small, the outer diameter clamping device 666 is moved to the outer wall of the injection molded part by clamping the mold taking manipulator, and the fixed block b4 is moved to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com