Manufacturing method of thin-walled stainless steel composite pipe

A production method and stainless steel technology, applied in the field of pipes, can solve the problems of insufficient performance and high cost of stainless steel drainage pipes, and achieve the effects of improving mechanical strength, satisfying mechanical properties, and increasing waist strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] 1) Make the inner circular pipe 1 with a metal tire mold 6 that can be reduced in diameter:

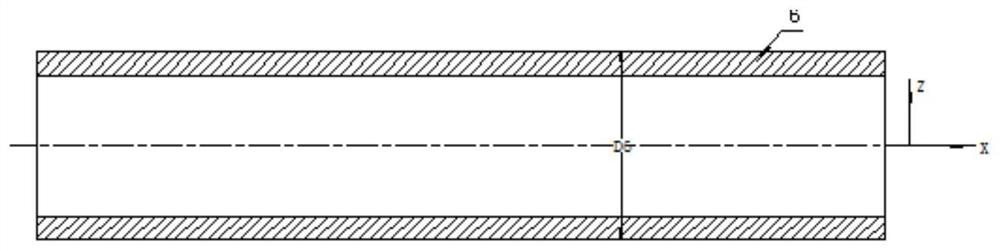

[0031] ① see figure 1 , The retractable metal tire mold 6 is cylindrical. It mainly refers to the tire mold manufactured by the German carat company as a model, and other tire models that can be reduced in diameter are all manufactured in imitation of the German carat company. This is a well-known product that is stereotyped. The structure will not be described in detail here.

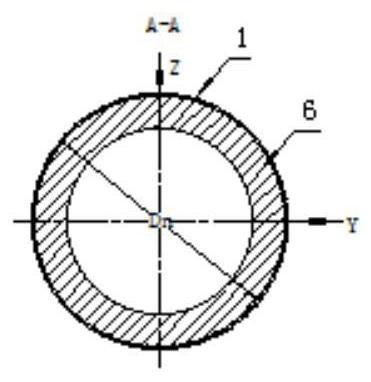

[0032] ② see figure 2 , image 3 , according to this embodiment, the thin-walled inner circular tube of the compound tube 1 has an inner diameter Dn=1600mm, a tube length L1=6000mm, and a wall thickness t 1 = 3mm, select tire mold 6 specifications: outer diameter D6 = Dn = 1600mm. (D6 see Figure 1).

[0033] ③Calculation of thin-walled inner circular pipe corrosion-resistant material thin-walled stainless steel plate materials are: stainless steel plate type 304L, plate thickness t1=3mm, each pl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com