A stable circular cutting mechanism

A cutting mechanism, circular technology, used in metal processing machinery parts, metal processing equipment, maintenance and safety accessories, etc., can solve the problems of unstable cutting fluid outflow, affecting the cutting effect of the cutter, and ensure cutting stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

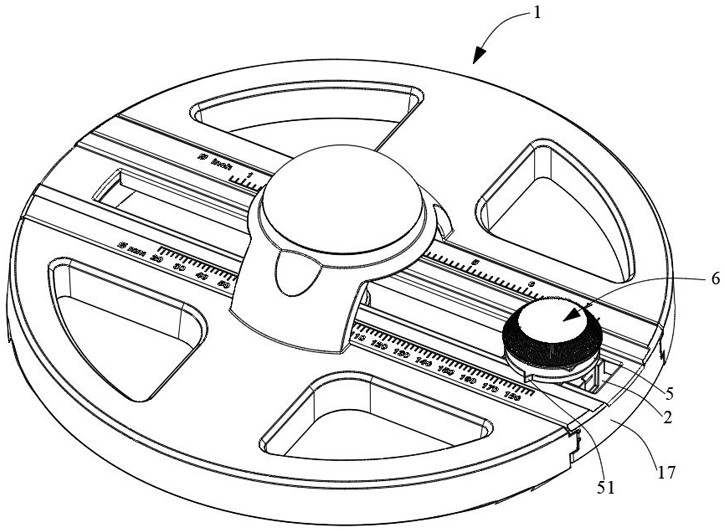

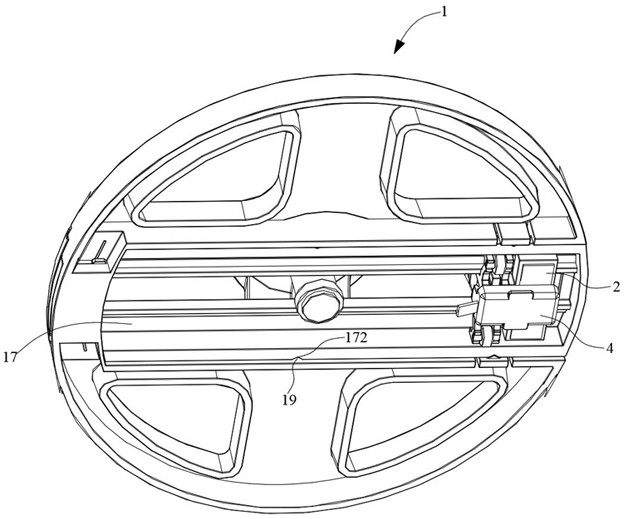

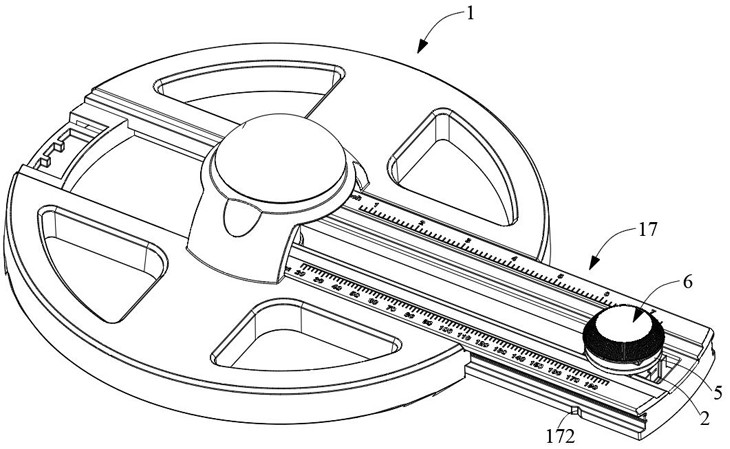

[0036] like Figure 1 to Figure 11 As shown, the existing circular cutting mechanism includes: a base 1, the base 1 is circular, and the center of the base 1 is provided with a rotating shaft 11, the specific installation method of the rotating shaft 11 is as follows: set up at the center of the upper end surface of the base 1 An arched top frame 12, the rotating shaft 11 passes through the top frame 12 and is rotatably connected with the top frame 12, the rotating shaft 11 passes through the base 1 downwards and protrudes from the lower end surface of the base 1, and a supporting sleeve is provided outside the lower half rotating shaft 11 13. The rotating shaft 11 is rotatably connected with the supporting sleeve 13. The supporting sleeve 13 is used to support on the cutting plane. A rotating knob 14 is fixed on the top of the rotating shaft 11. The rotating knob 14 is a quarter sphere. By rotating The top frame 12 realizes the rotation of the base 1. In order to ensure the s...

Embodiment 2

[0067] On the basis of the first embodiment, the second embodiment also provides a method for using a stable circular cutting mechanism, wherein a stable circular cutting mechanism is the same as the first embodiment, and will not be repeated here.

[0068] Further, remove the knife cover 4, and insert the insertion slot 25 through the plug block 42, so that the knife cover 4 is hung on the side wall of the sliding seat 2; push the sliding seat 2 to slide, and push the blocking block 46 to the stopper through the top block 26. The plate 47 is separated from the inner side wall of the receiving groove 43, so that the cutting fluid in the receiving groove 43 flows back into the liquid storage chamber 21; the cutting fluid is added to the liquid storage chamber 21 through the liquid inlet 49; the sliding seat is reversely pushed 2 Slide to make the pointer 51 point to the preset position; turn the finger ring 5 until the through hole 271 is opposite to the liquid outlet channel 22...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com