Electrical automatic machining device

An electrical automation and mechanical processing technology, applied in metal processing equipment, manufacturing tools, welding equipment, etc., can solve the problems of entering the inside of the machine body, damage to the laser cutting head, and reduced cleanliness inside the machine body, so as to ensure cleanliness and normal operation. Enables, enhances the effect of flexibility of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

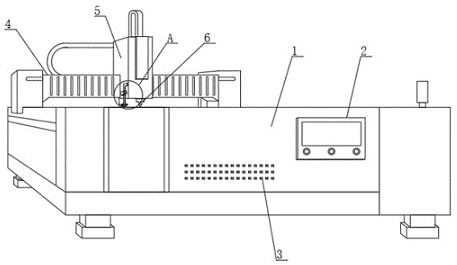

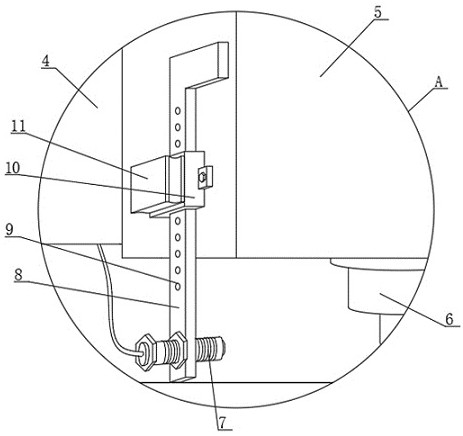

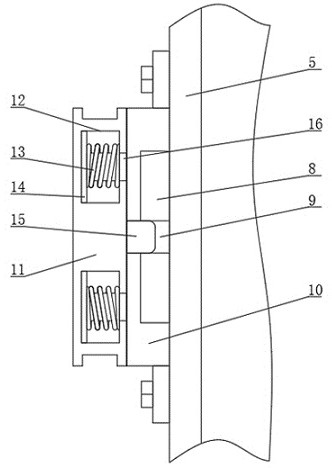

[0027] see Figure 1 to Figure 5 , the present invention provides a technical solution: an electrical automatic machining device, comprising a machine body 1 and a moving beam 4 arranged on the top of the machine body 1, and a cutting machine base 5 is slidably installed on the moving beam 4, and the bottom of the cutting machine base 5 A laser cutting head 6 is arranged at the end, and a temperature control mechanism is arranged on the cutting machine base 5. The temperature control mechanism includes a central control unit, a temperature control module, a display module and a temperature sensor 7. The temperature control module is connected with the central control unit, and the display module passes The data line is connected to the temperature control module, and the display module is also connected to the display screen 2 through the connection line for displaying temperature information. The temperature sensor 7 is connected to the data receiving module through the connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com