A kind of preparation technology of penicillin preparation

A preparation process, penicillin technology, applied in the direction of packaging automatic control, packaging, sorting, etc., can solve the problems of inability to realize real-time monitoring, inability to achieve comprehensive detection, waste of raw materials, etc., achieve short measurement time, reduce production efficiency, The effect of reducing the defective rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

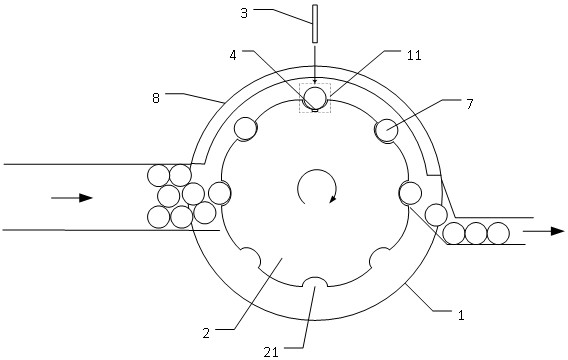

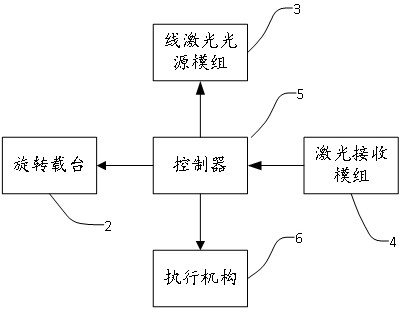

[0065] In the entire preparation process of penicillin preparations, the most likely cause of defective products is that the deviation between the filling dose and the standard dose exceeds the specified value. Through long-term production practice, it has been found that more than 90% of the defective products with different weights are caused by insufficient filling dosage caused by the failure of packaging equipment, and the situation of defective products caused by excessive filling dosage is relatively low. few.

[0066] The current weight inspection is by manual sampling, and the proportion of random inspection is low, usually only about 1%. The filling dose of a certain batch is judged by the results of random inspection. This method is less comprehensive and has a lag.

[0067] Based on this, in this embodiment, the following detection process is added to the penicillin preparation preparation process, specifically including the following steps:

[0068] S401. Determ...

Embodiment 1

[0098] Embodiment 1: the preparation technology of penicillin sodium for injection

[0099] Remove the outer packaging of the 7ml molded vials and place them on the bottle unscrambling table. After rejecting unqualified bottles, the undamaged vials are neatly arranged and pushed to the bottle delivery mesh belt to be washed, and then sent to the bottle turntable by the conveyor belt, and then sent to the ultrasonic wave. Bottle washing machine. After ultrasonic cleaning, purified water and water for injection rinse, the cleaned bottles are blown with nitrogen and sent to the mouth of the tunnel oven through a conveyor belt under A-level laminar flow protection, and pushed into the tunnel oven by a bottle pusher for high-temperature sterilization and drying. Among them, the water pressure of purified water is ≥0.2MPa, the water pressure of injection water is ≥0.2MPa, and the pressure of high-pressure nitrogen gas is ≥0.2Mpa.

[0100] Use KSZ1200 / 180 tunnel type sterilization a...

Embodiment 2

[0116] The penicillin sodium of embodiment 1 is replaced by azlocillin sodium, amosodium, ampicillin sodium, oxacillin sodium, furobuta sodium, cloxacillin sodium, mezacillin sodium, piperacillin sodium, and other technological processes are not changed. Change. The results show that the penicillin preparation preparation process of the present invention has an accurate subpackage volume and meets preset requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com