Garbage treatment equipment for building construction

A technology for waste treatment equipment and construction, applied in the field of waste treatment equipment for construction, can solve the problems of poor filtering effect, inability to achieve crushing effect, lack of auxiliary filtering by filter plates, etc., and achieve the effect of improving crushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

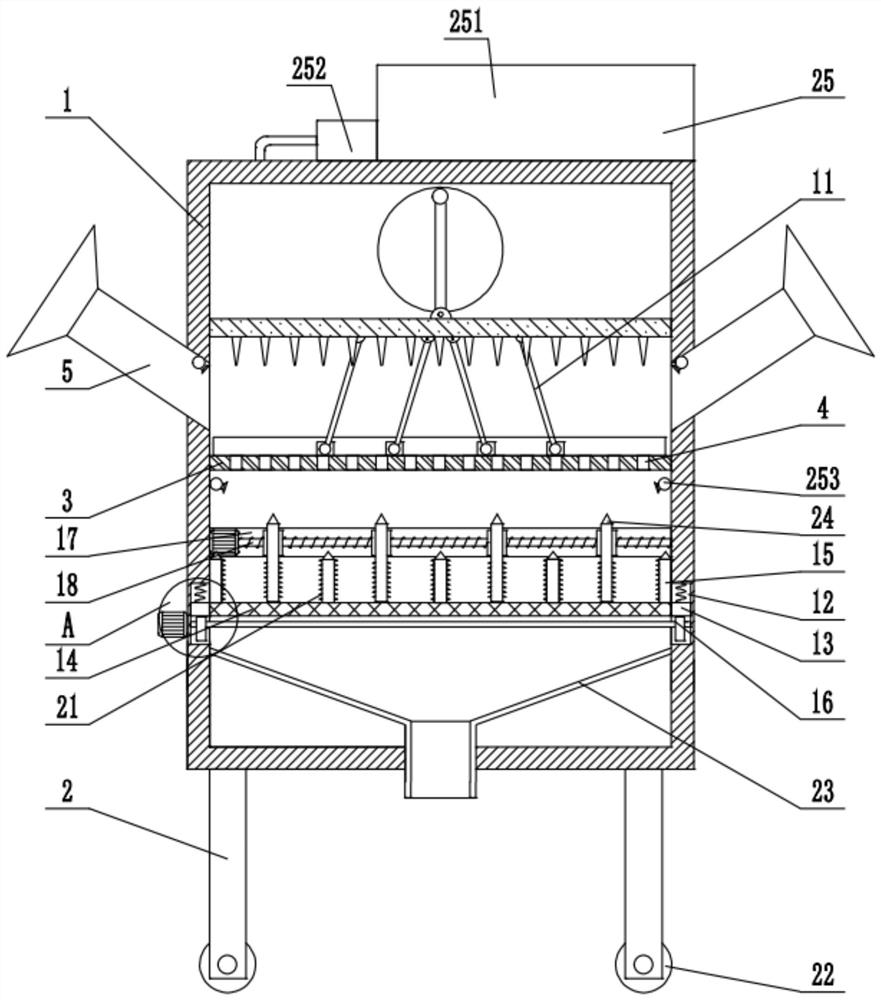

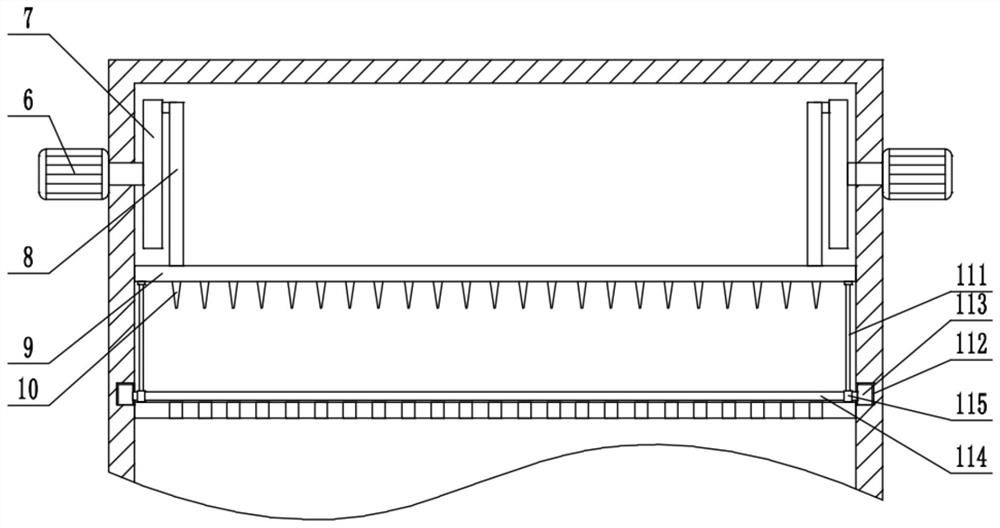

[0025] see Figure 1-5 , a kind of garbage treatment equipment for building construction, comprising a box body 1, support legs 2 are fixedly installed around the bottom of the box body 1, and inclined feed pipes extending into the box body 1 are fixedly installed on the left and right side walls of the box body 1 respectively 5. The first filter plate 3 is fixedly installed between the inner walls of the box body 1 below the feed pipe 5. There are multiple groups of filter holes 4 evenly distributed on the first filter plate 3, and the front and rear side walls of the box body 1 are respectively fixed. A motor 6 is installed, and the output shaft of the motor 6 extends into the box body 1 and is fixedly connected with a vertical rotating disk 7. Push-pull rods 8 are installed on the opposite side walls of the left and right two groups of rotating disks 7, respectively. The bottom ends of the rods 8 rotate together and are installed with a horizontal impact plate 9 that is sli...

Embodiment 2

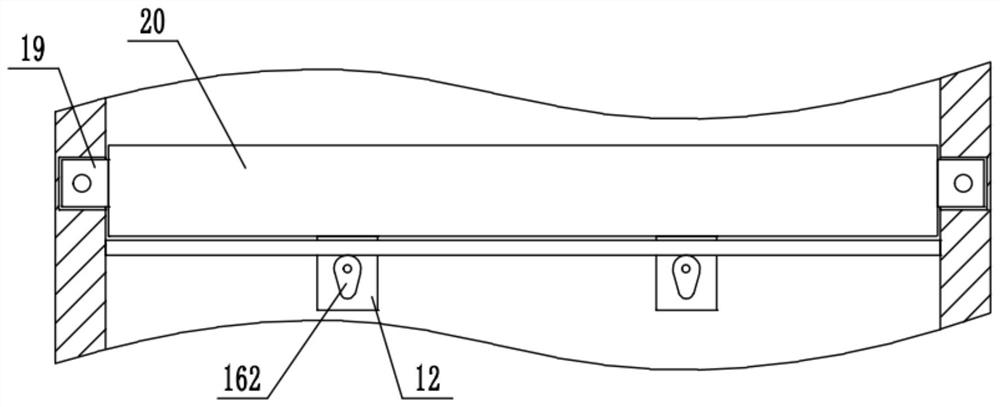

[0027]On the basis of Embodiment 1, a roller 22 is mounted on the bottom of the supporting leg 2, and the position of the entire device is facilitated by the roller 22. The dust reduction component 25 includes a water tank 251 fixedly installed on the top of the box body 1, and the water tank 251 communicates with a fixed The pump machine 252 on the top of the box body 1, the pump machine 252 is connected with multiple sets of spray pipes 253 fixed between the inner walls of the box body 1, and the spray pipe 253 is fixedly equipped with multiple groups of atomizing nozzles distributed at equal intervals, and the material pushing parts 11 It includes the chute 112 opened on the side wall of the box body 1 on the front and rear sides of the first filter plate 3. There are multiple sets of sliders 113 slidingly installed in the chute 112, and the sliders 113 on the left and right sides are jointly connected with multiple sets of material shifting rods. 114, the left and right two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com