Refractory material production system

A production system and technology of refractory materials, applied in loading/unloading, conveyors, grain processing, etc., can solve the problems of shortened labor time, inconvenient use of screening devices, etc., and achieve the effect of continuous and stable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

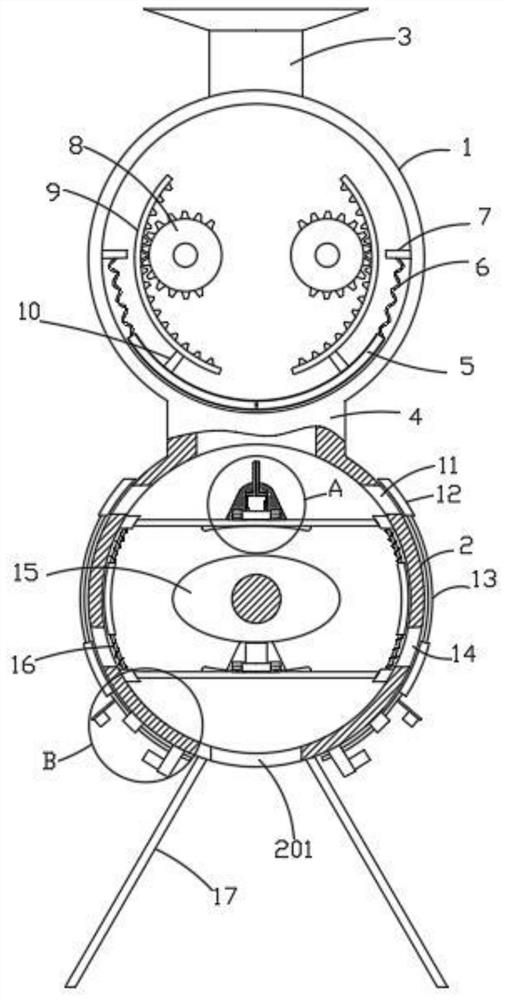

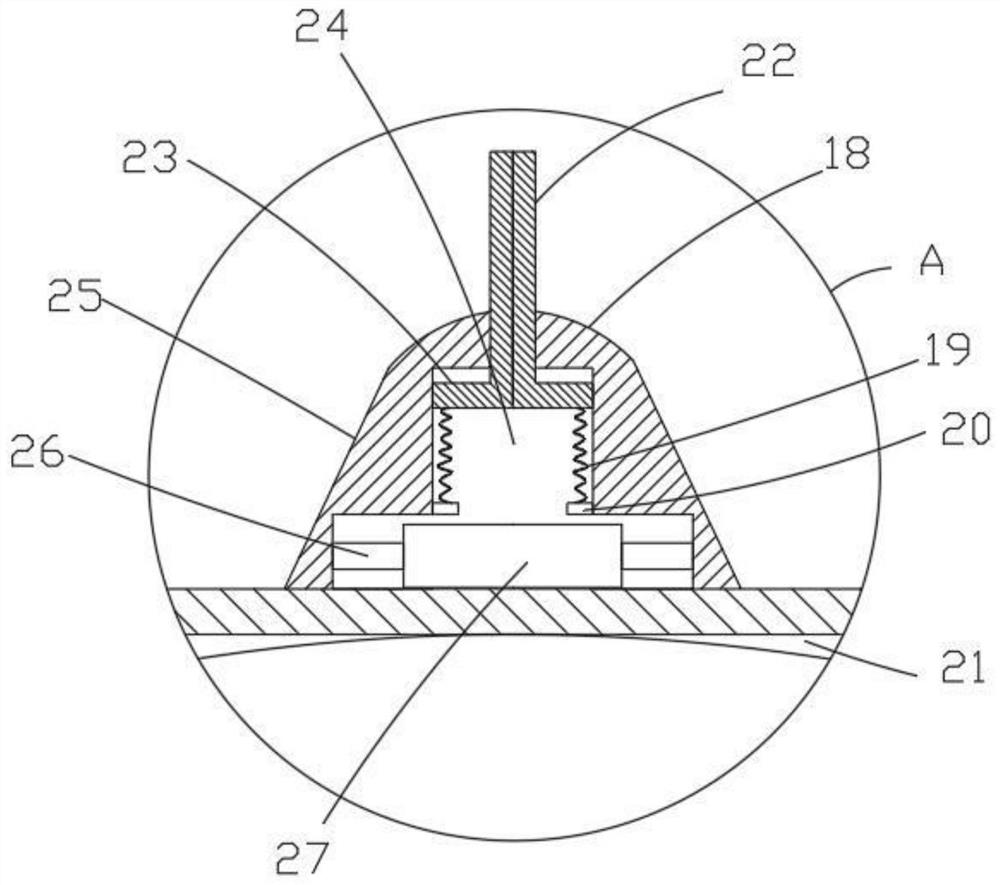

[0029] See Figure 1-5 , A refractory material production system includes a raw material crushing device, a re-crushing device, a screening device, a ball mill, an iron apparatus, a mixture apparatus, a molding apparatus, and a kiln.

[0030] The screening device includes a horizontal arrangement and a cylindrical storage cartridge 1 and a screen cartridge 2, and a tape 3 is disposed between the top of the storage cartridge 1, and the storage cartridge 1 and the sieve cartridge 2 are connected. 4 Connect, the batch sheet is provided in the storage cartridge 1 to allow the upper port of the connecting pipe 4 to be closed.

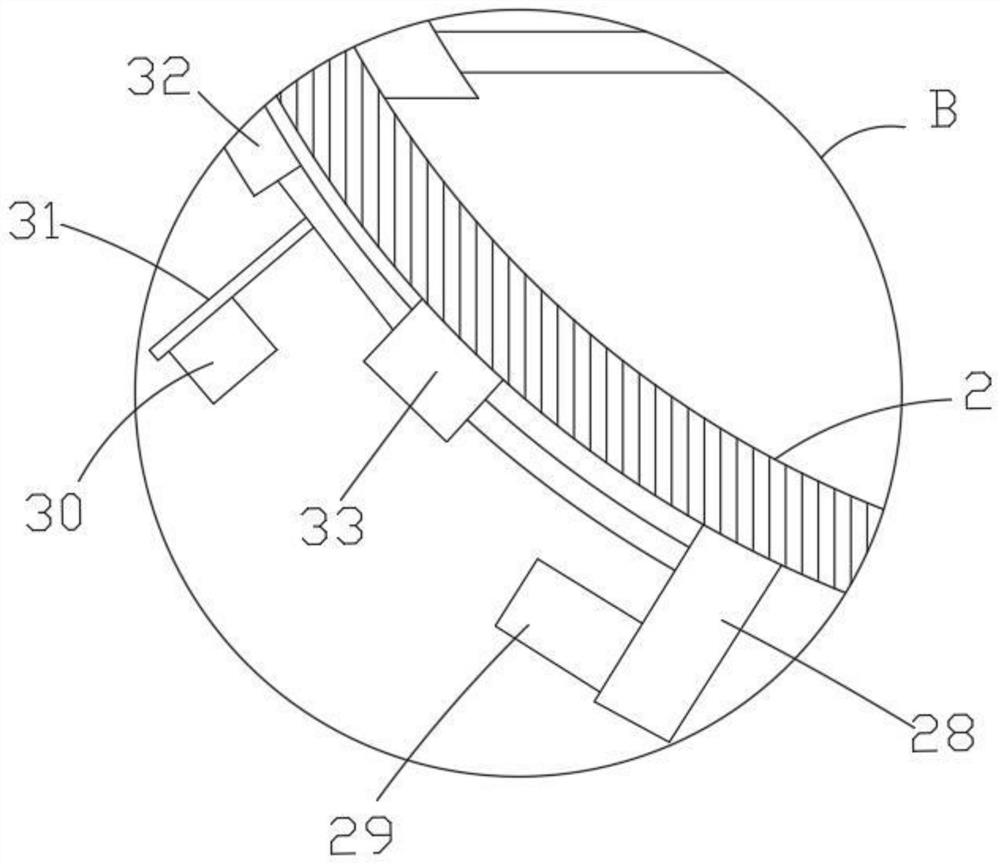

[0031] The screen discharge cartridge 2 is spaced apart from the two parallel sieve plates, and the two ends of the two screen plates are slidably connected in the inner wall of the screen cartridge 2, wherein the number of screen panels at the bottom is greater than the number of screen panels above, two The screening cartridge 2 is provided between the screen p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com