A shoe sole hemming device for shoe production

A technology for edging and shoes, which is applied in footwear, application, and shoe-making machinery, etc., can solve the problems that the edging cannot be standardized, and the length of the reserved edging cannot be pressed down quickly, so as to achieve the effect of improving the stability of the edging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] This example is an embodiment of a shoe production sole stacking device.

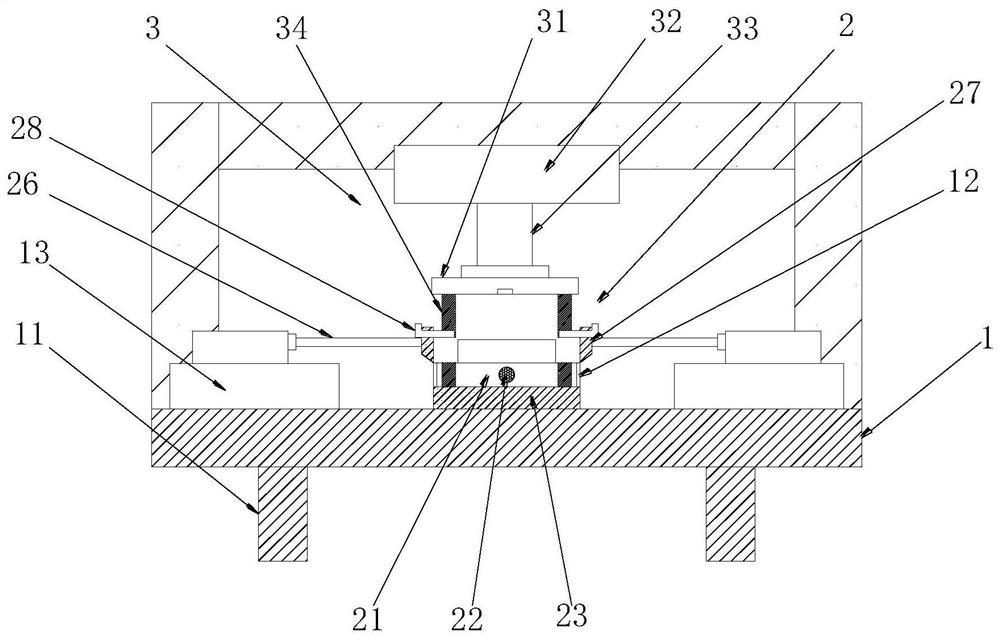

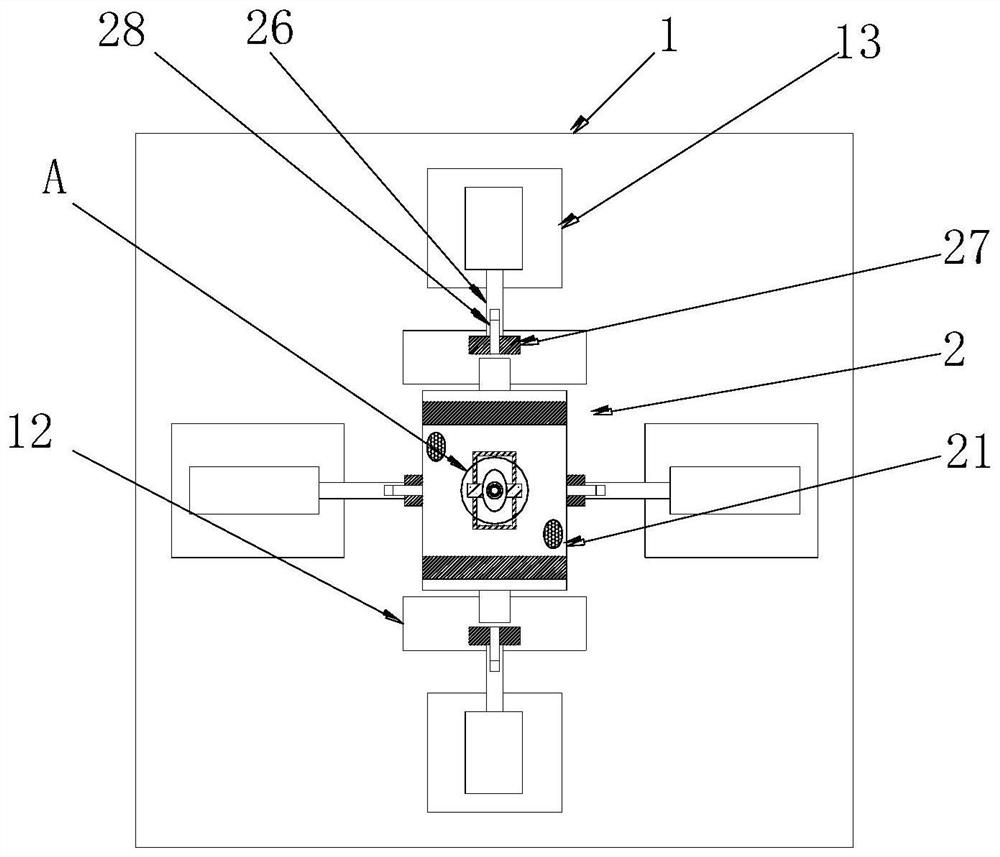

[0024] See Figure 1-4 One shoe production sole laminated device, including the laminated base 1, the bottom of the laminated base 1 is fixedly connected to the fixed support leg 11, and the top fixed connection of the overlay base 1 is fixedly connected with a stacked support block 12, stack The inside of the side support block 12 is provided with a laminate mechanism 2, and a lower pressure mechanism 3 is provided with a lower portion of the overlapping base 1, and a clamping active base block 13 is fixed.

[0025] Through the above technical solution, the overlapping edge support block 12 at which the overlapping base 1 fixedly connected can be a flipping support point of the laminated flip plate 21, followed by clamping activity blocks provided on the left and right sides of the overlay support block 12. 13. The fixed fulcrum can be provided for the electric telescopic sleeve, and then control the...

Embodiment 2

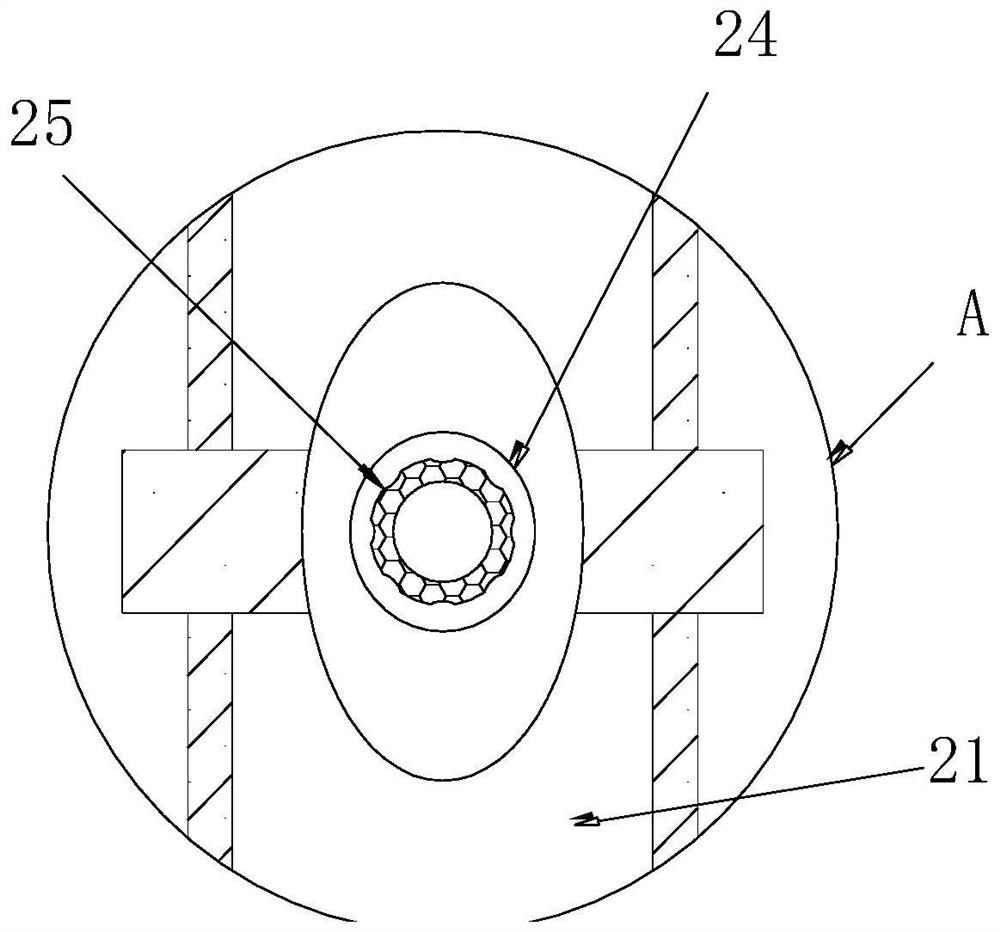

[0040] This example is an embodiment of a superposition mechanism for the production of the sole laminated device.

[0041] A laminate mechanism 2 of a shoe production sole laminated device includes a laminated flip plate 21, and a positive and inverse two-sided surface of the laminated flip plate 21 fixes the flip rotating shaft 22, and the bottom sliding connection of the laminated flip plate 21 has a lower pressure support. The block 23, and the inner portion of the laminated flip plate 21 is provided with a laminated reserved sleeve 24, and the inner thread of the overlay reserved sleeve 24 is connected to the overlay adjustment rod 25, and the inner sliding connection of the laminated flip plate 21 is telescopically. The nut 26, and one end of the telescopic nut 26 fixed to the clamping pad 27, and the inner slide of the clamping pad 27 is slidably connected to the overlay sliding spacer 28.

[0042] In the above embodiment, the overlapping of the overlapping reserved sleeve ...

Embodiment 3

[0044] This example is an embodiment of a lower pressure mechanism for a shoe production sole stacking device.

[0045] A lower pressure mechanism 3 for the production of the sole laminated device includes a lower pressure plate 31, and a hydraulic cylinder 32 is provided with a hydraulic cylinder 32, and the inner wall activity of the hydraulic cylinder 32 is connected to the hydraulic rod 33, the bottom of the hydraulic rod 33 and the lower The top of the pressure plate 31 is fixed, and the bottom pressure stabilizer 34 is fixedly connected to the bottom of the lower pressure plate 31.

[0046] In the above embodiment, the inner portion of the laminated flip plate 21 is slidably linked to the outer surface of the lower pressure stabilizer 34, thereby ensuring that the lower pressure plate 31 is pressed against the sole and the sole is down pressure, the lower pressure plate 31 does not shift, increase the overlay stability of the lower pressure mechanism 3, and the fixed groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com