A polyurethane sole

A polyurethane and shoe sole technology, applied in the field of polyurethane shoe soles, can solve problems such as poor thermal insulation effect and cold feet, and achieve the effect of expanding the use function and enhancing the use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

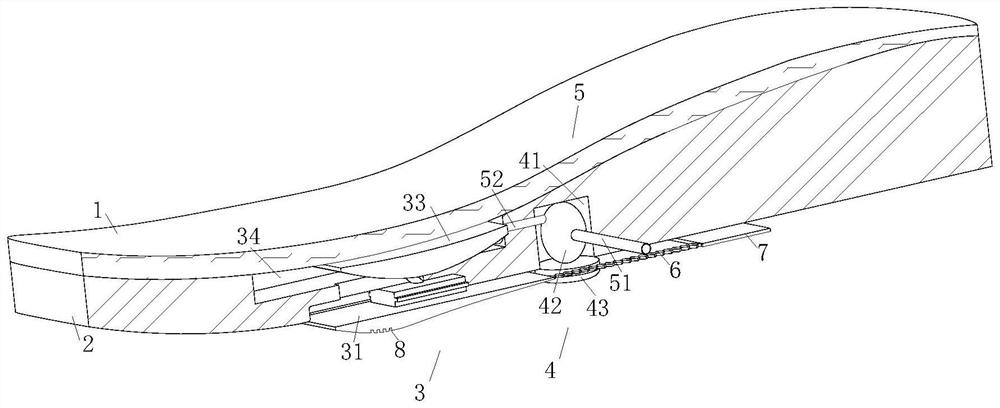

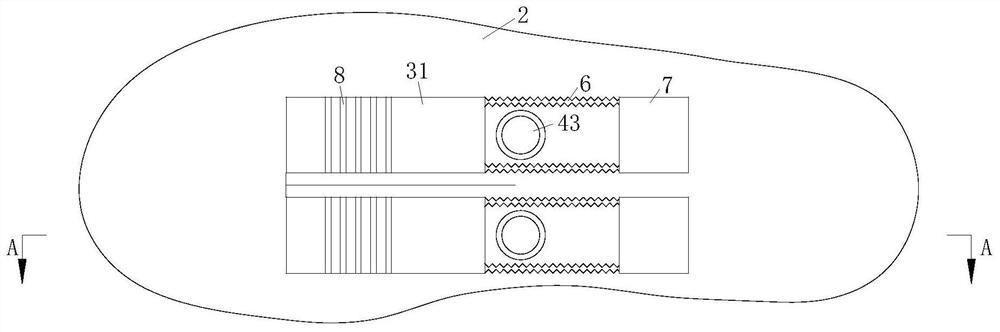

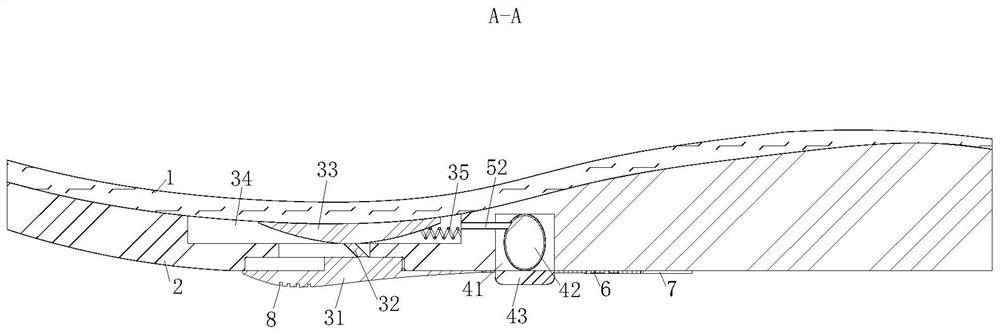

[0026] As an embodiment of the present invention, the ventilation module 5 comprises a one-way air intake 51 and a one-way outlet port 52; one end of the one-way air intake port 51 is communicated with the side of the airbag 42, the other end of the one-way air intake port 51 is in communication with the second cavity 41; one end of the unidirectional outlet port 52 communicates with the airbag 42, and the other end of the unidirectional outlet port 52 communicates with the first cavity 34; when working, the present invention is provided on the shock absorption module 41 with a breathable module 5, when the elastic block 43 is squeezed on the airbag 42, So that the gas in the airbag 42 is blown into the first cavity 34 from the one-way outlet port 52, so that the hot gas generated in the first cavity 34 flows, so that the effect of heating and holding is better; when the gas in the airbag 42 is reduced, the airbag 42 presents a negative pressure state, so that through the one-way ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com