Heating structure and atomizer

A technology for atomizers and heating elements, which is applied in the direction of tobacco, etc., can solve the problems of sticky core and uneven temperature of heating structure, and achieve the effect of avoiding burnt core and uniform temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

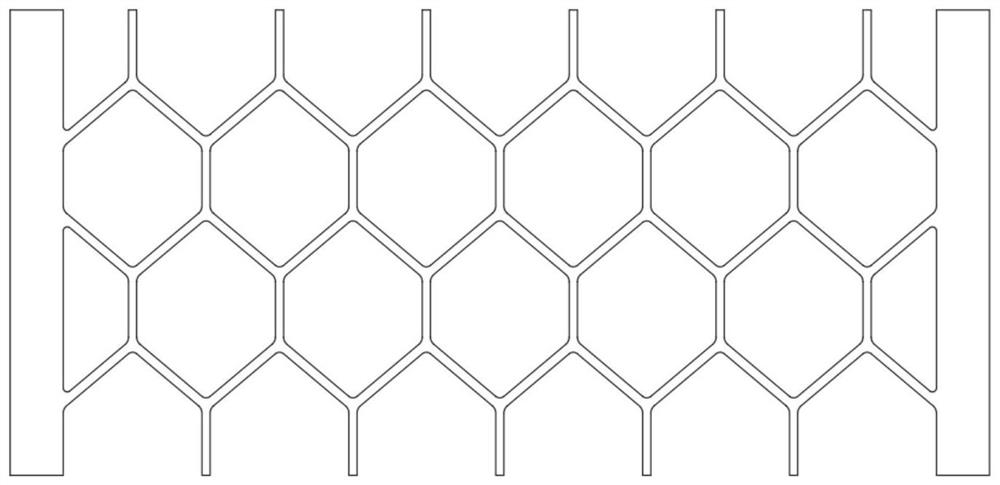

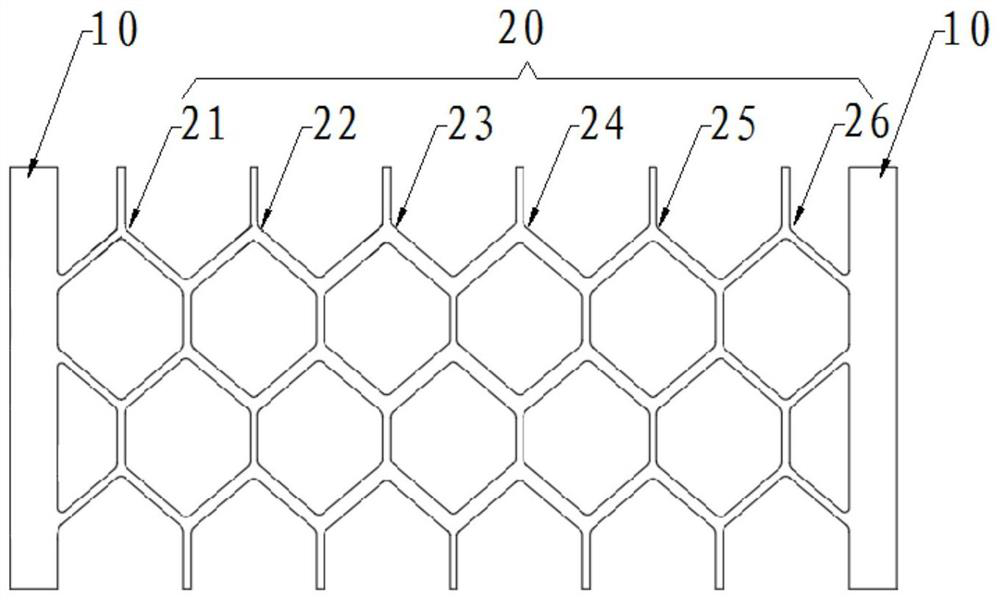

[0041] The heating element 20 is made of nickel-chromium alloy (Cr20Ni80), the thermal conductivity is 60.3W / (m c), the resistivity is 1.09E-06Ω.m, the shape of the heating unit is hexagonal, the total length of the heating structure is 12mm, and the total width 5.7mm, thickness 0.1mm.

[0042] see figure 2 The wire width of the first heating unit 21 and the sixth heating unit 26 is 0.1 mm, the wire width of the second heating unit 22 and the fifth heating unit 25 is 0.2 mm, and the wire width of the third heating unit 23 and the fourth heating unit 24 The width is 0.25mm.

[0043] After testing, the temperature at the first heating unit 21 and the sixth heating unit 26 is 280°C, the temperature at the second heating unit 22 and the fifth heating unit 25 is 285°C, the third heating unit 23 and the fourth heating unit 24 The temperature at 281°C is basically the same.

Embodiment 2

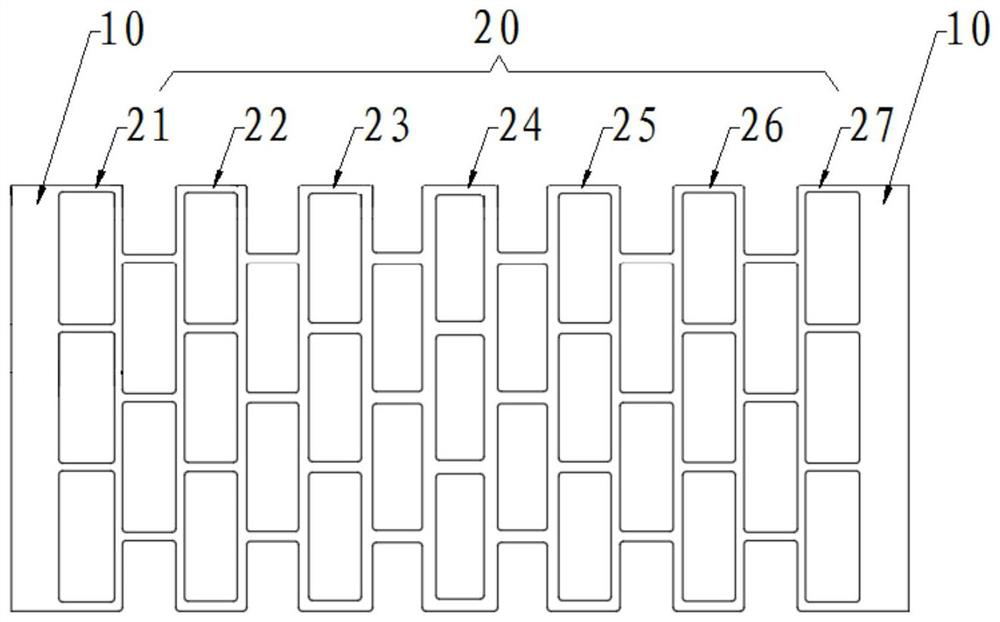

[0045] The heating element 20 is made of nickel-chromium alloy (Cr20Ni80), the thermal conductivity is 60.3W / (m c), the resistivity is 1.09E-06Ω.m, the shape of the heating unit is rectangular, the total length of the heating structure is 12mm, and the total width is 5.7mm , thickness 0.1mm.

[0046] see image 3The wire width of the first heating unit 21 and the seventh heating unit 27 is 0.1 mm, the wire width of the second heating unit 22 and the sixth heating unit 26 is 0.15 mm, and the wire width of the third heating unit 23 and the fifth heating unit 25 The width is 0.2 mm, and the wire width of the fourth heating unit 24 is 0.25 mm.

Embodiment 3

[0048] The heating element 20 is made of nickel-chromium alloy (Cr20Ni80), the thermal conductivity is 60.3W / (m c), the resistivity is 1.09E-06Ω.m, the shape of the heating unit is rhombus, the total length of the heating structure is 12mm, and the total width is 5.7mm , thickness 0.1mm.

[0049] see Figure 4 The wire width of the first heating unit 21 and the sixth heating unit 26 is 0.1 mm, the wire width of the second heating unit 22 and the fifth heating unit 25 is 0.15 mm, and the wire width of the third heating unit 23 and the fourth heating unit 24 The width is 0.2 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com