Low-salt and low-nitrite leaf mustard fermentation technology

A low nitrite, mustard green technology, applied in the direction of bacteria, food science, and application used in food preparation, can solve problems such as environmental pollution and waste of resources, and achieve the effects of improving utilization, improving safety, and shortening fermentation cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] 1) Processing of raw materials: carefully wash 1000g of fresh mustard greens, cut them into pieces, and put them in a fermentation jar for compaction;

[0047] 2) Mix raw and auxiliary materials: add 35g and 15g of white sugar, and 120ml of NaCl solution with a mass concentration of 3% in the fermentation jar, and fully mix and stir;

[0048] 3) Add marinade: add 250ml of desalted naturally fermented mustard refined marinade in the fermentation jar, and mix with it;

[0049] 4) Inoculation of compound strains: measure the OD value of the mixed strains and dilute to 10 -5 cfu / m 3 , inoculate 250ml of high-density cultured mixed strains in the fermentation jar;

[0050] 5) Fermentation: Seal the fermentation jar for fermentation, and continue to ferment for 25 days at an ambient temperature of 33°C;

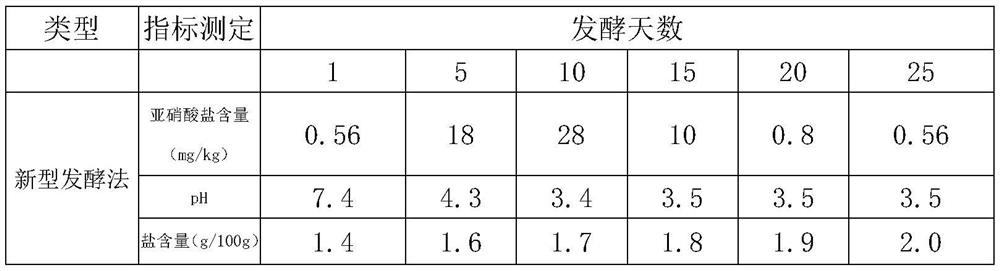

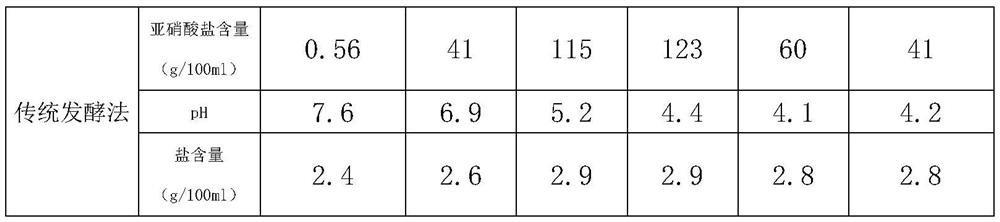

[0051] 6) Detection: Take a sample every 5 days to measure and analyze the physical and chemical indicators of nitrite, total acidity, and total salinity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com