Olive freeze-dried powder preparation method and olive freeze-dried powder

A technology of freeze-dried powder and olive, which is applied in the preparation of olive freeze-dried powder and the field of olive freeze-dried powder, which can solve the problems of unstable biological active ingredients, no longer retaining fruit flavor, and damage to functional ingredients of fruit powder, so as to reduce transportation and production costs. cost, shortened freeze-drying time, and improved recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A preparation method of olive freeze-dried powder:

[0032] S1. Take the olives out of the freezer and thaw them. The thawing temperature is 90°C, and the thawing time is 20 minutes. Put the thawed olives in a pitting machine for pitting treatment, and at the same time manually remove the olives that have not been cleaned. If the nucleus is detected, a seedless olive is obtained;

[0033] S2. Put seedless olives in an enzymatic hydrolysis tank, pour 0.5 times the weight of seedless olives into pure water, 0.3‰ pectinase and 0.2‰ cellulase, and enzymatically Decompose for 1.5h to obtain enzymatic hydrolyzed olives;

[0034] S3, placing the enzymatically hydrolyzed olives in a belt press to extract juice, and filtering with a 200-mesh filter cloth to obtain olive stock solution;

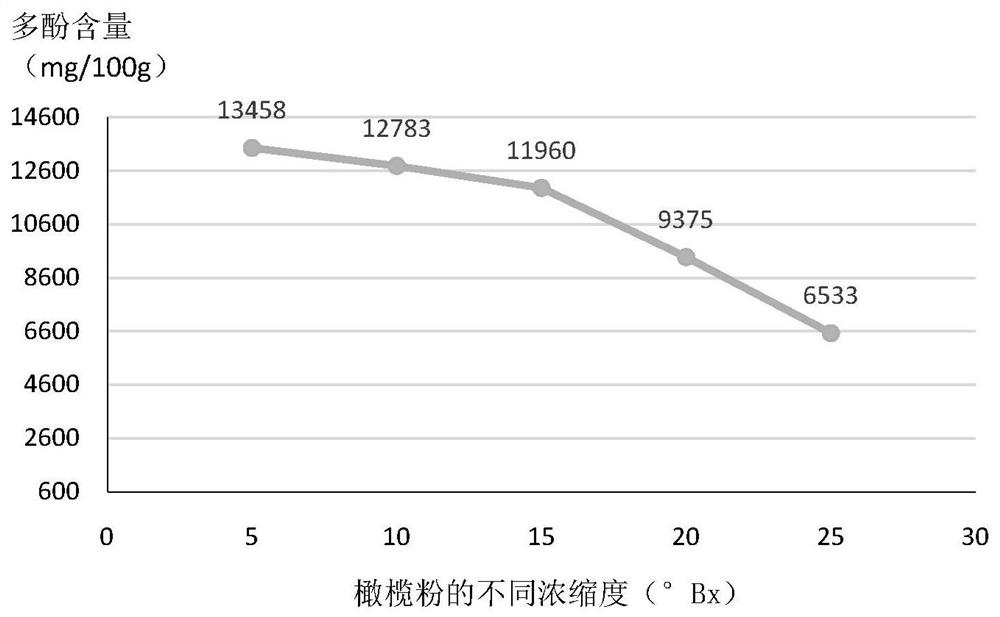

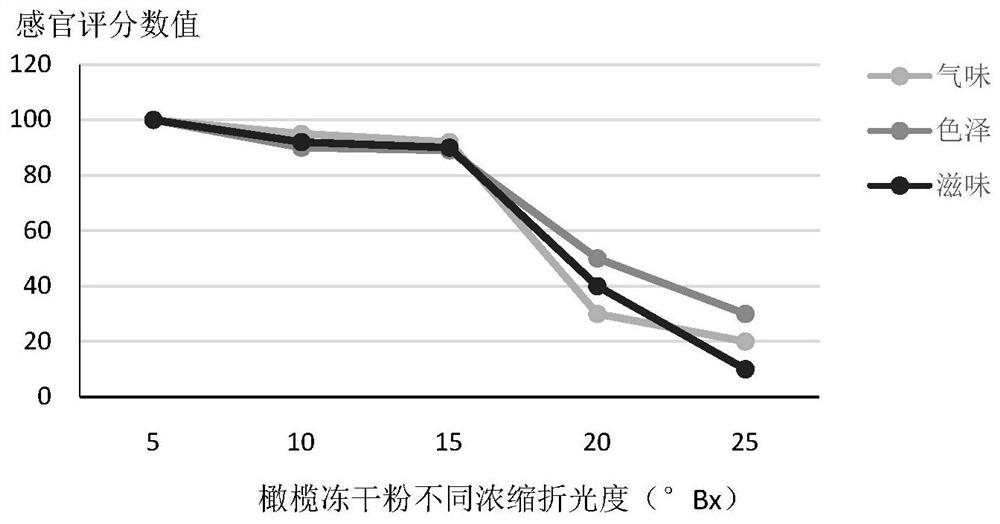

[0035] S4. Put the olive stock solution in a vacuum concentration pot for vacuum concentration, the vacuum degree of vacuum concentration is -0.1MPa, the temperature of vacuum concentration is...

Embodiment 2

[0040] A preparation method of olive freeze-dried powder:

[0041] S1. Take the olives out of the freezer and thaw them. The thawing temperature is 70°C and the thawing time is 30 minutes. If the olive pit is detected, a seedless olive is obtained;

[0042] S2. Put seedless olives in an enzymatic hydrolysis tank, pour 0.5 times the weight of seedless olives into pure water, 0.1‰ pectinase and 0.1‰ cellulase, and enzymatically Decompose for 2 hours to obtain enzymatic hydrolyzed olives;

[0043] S3, placing the enzymatically hydrolyzed olives in a belt press to extract juice, and filtering with a 100-mesh filter cloth to obtain olive stock solution;

[0044] S4, the olive stock solution is placed in a vacuum concentration pot for vacuum concentration, the vacuum degree of vacuum concentration is -0.05MPa, the temperature of vacuum concentration is 40°C, the olive stock solution is concentrated to a sugar content of 15°Bx, and the olive concentrate is obtained;

[0045] S5, p...

Embodiment 3

[0049] A preparation method of olive freeze-dried powder:

[0050] S1. Take the olives out of the freezer and thaw them. The thawing temperature is 100°C and the thawing time is 10 minutes. If the olive pit is detected, a seedless olive is obtained;

[0051] S2. Put seedless olives in an enzymolysis tank, pour 0.5 times the weight of seedless olives into pure water, 0.5‰ pectinase and 0.5‰ cellulase, and enzymatically Decompose for 0.6h to obtain enzymatic hydrolyzed olives;

[0052] S3, placing the enzymatically hydrolyzed olives in a belt press to extract juice, and filtering with a 300-mesh filter cloth to obtain olive stock solution;

[0053] S4. Put the olive stock solution in a vacuum concentration pot for vacuum concentration, the vacuum degree of vacuum concentration is -0.1MPa, the temperature of vacuum concentration is -55°C, the olive stock solution is concentrated to a sugar content of 20°Bx, and the olive concentrate is obtained;

[0054] S5, pre-freezing the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com