A kind of aqueous mixed electrolyte and its application in zinc ion hybrid supercapacitor

A supercapacitor and electrolyte technology, applied in the field of electrochemical energy storage, to achieve the effects of improving conductivity, fast and efficient adsorption and desorption reactions, and broadening the working temperature and application range

Active Publication Date: 2022-05-31

DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

View PDF9 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

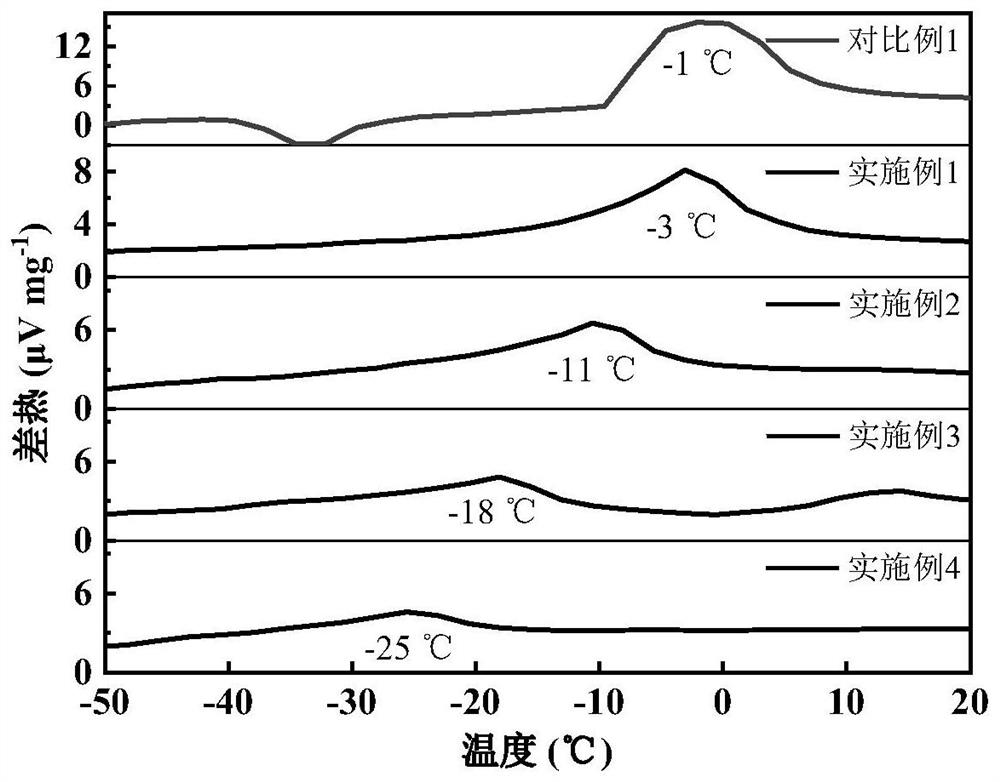

However, due to the high freezing point of water, the system cannot operate at lower temperatures. Adding organic solvents and using organic zinc salts as solutes to construct a mixed electrolyte with a low freezing point is essential for improving the low-temperature performance of zinc-ion hybrid supercapacitors. important

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

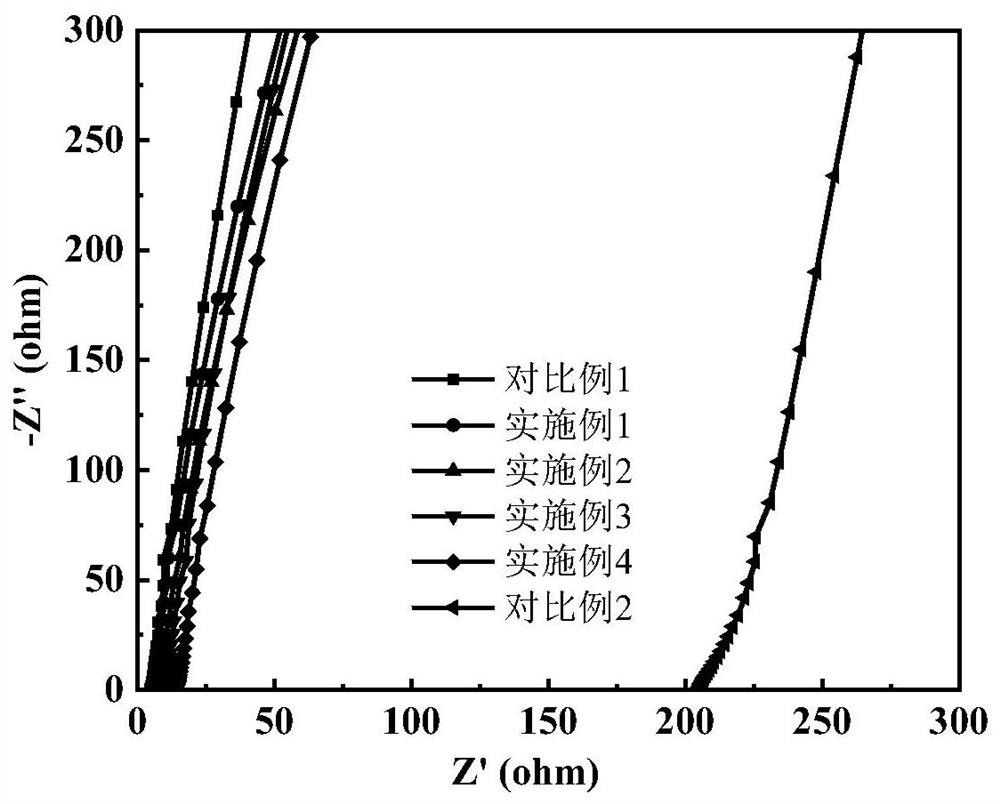

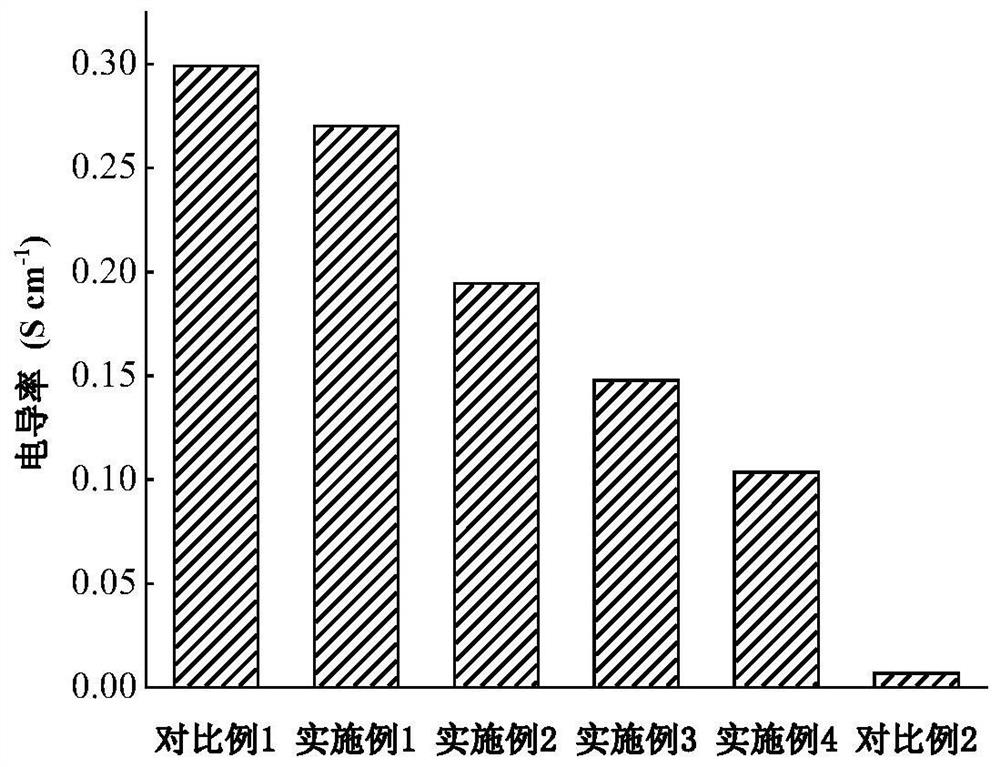

The invention relates to an aqueous mixed electrolyte and its application in a zinc ion mixed supercapacitor. Disclosed is a mixed electrolyte comprising an organic zinc salt as a solute and water and ethylene glycol as a solvent, which has an ion conductivity comparable to that of an aqueous solution and a lower freezing point (<‑20°C). The interaction between ethylene glycol and the anions in the organic zinc salt changes the solvation state of the zinc ions in the mixed electrolyte, reduces the electron cloud density of hydrogen in the hydration structure of the zinc ions, effectively inhibits the hydrogen evolution reaction, broadens its potential window, and slows down the production of water-based batteries. Effect of gas on cycle stability. The adsorption of zinc ions on the surface of activated carbon is enhanced, and a faster and more efficient adsorption-desorption reaction can occur on the surface of activated carbon, which improves the specific capacity of the hybrid supercapacitor. The introduction of ethylene glycol and organic zinc salt can greatly increase the conductivity of the mixed electrolyte at low temperature, thereby increasing the power density of the hybrid supercapacitor at low temperature, thereby broadening its operating temperature and application range.

Description

An aqueous mixed electrolyte and its application in zinc ion hybrid supercapacitors technical field The present invention relates to the field of electrochemical energy storage, particularly a kind of water-based mixed electrolyte and its zinc ion mixed ultra-high applications in grade capacitors. Background technique [0002] With the development of intelligent electronic equipment, electric vehicles and other fields, people are concerned about the energy density, fast charging of energy storage equipment. The requirements for discharge performance and safety performance are getting higher and higher. Zinc-ion secondary battery is a new type of high-efficiency rechargeable battery. source rich zinc (theoretical specific capacity is 823mAh g -1 ) instead of lithium sodium as the negative electrode material, not only the preparation process is simple, the battery material It is non-toxic and inexpensive, the discharge process is safe, and it has high energy density...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): H01G11/58H01G11/06

CPCH01G11/58H01G11/06Y02E60/13

Inventor 李先锋常娜娜尹彦斌宋杨王胜男张华民

Owner DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com