Hinged buffer self-anchored buried oil and gas pipeline static explosion experiment device

A technology for oil and gas pipelines and experimental devices, which is applied to measuring devices, instruments, scientific instruments, etc. It can solve the problems that the impact of blasting load cannot be alleviated, and the impact of blasting load cannot be independently measured, so as to ensure the independence of deformation and optimize the fastening effect. , the effect of ensuring independence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

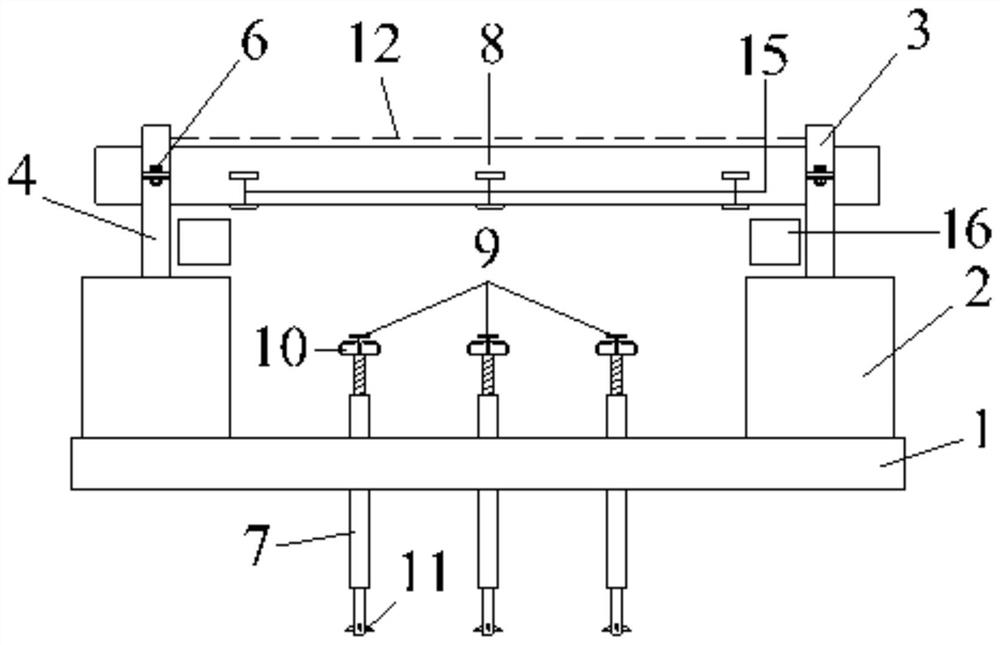

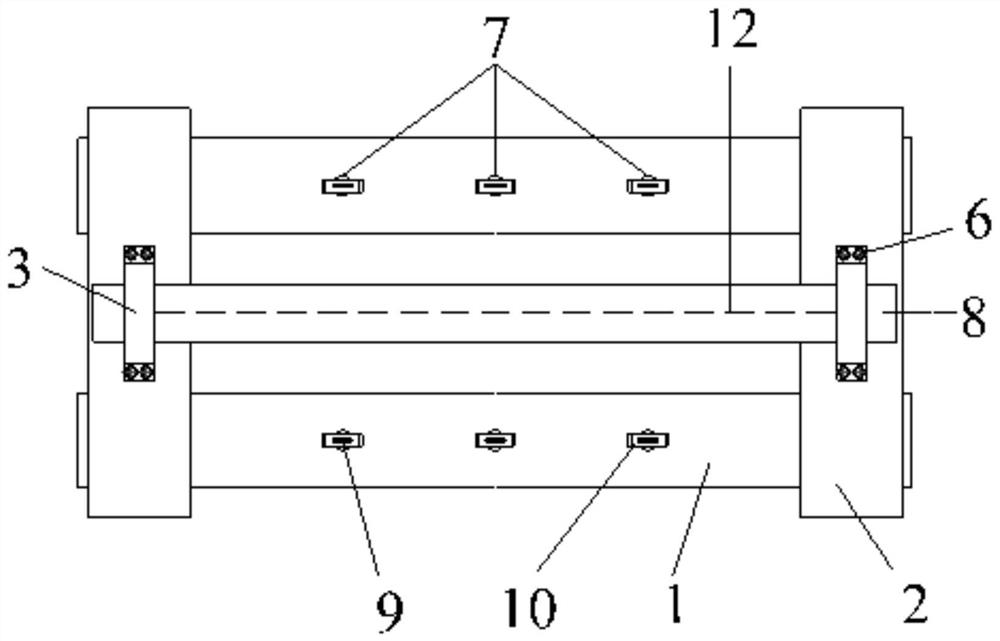

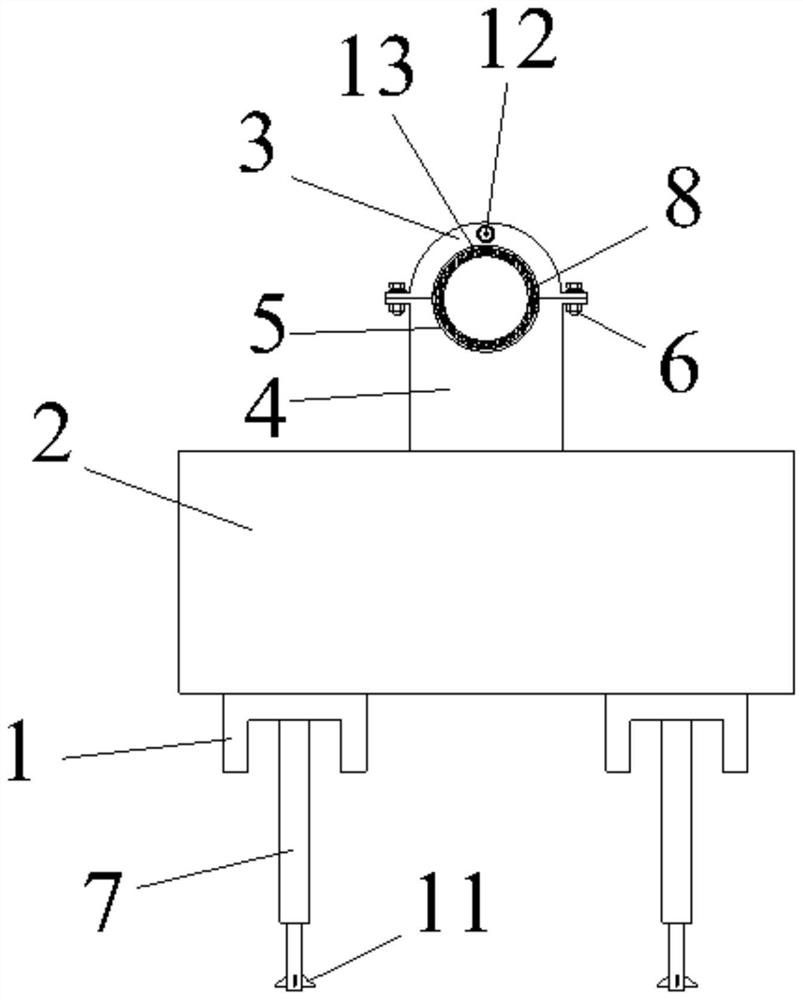

[0029] like Figure 1-3 As shown, the hinged buffer self-anchored buried oil and gas pipeline static explosion test device provided by the present invention includes: channel steel 1, a plurality of adjustable ground anchor mechanisms 7, two spherical hinge spring supports, a plurality of pressure sensors 15, The acceleration sensor 16 and the data processor, the channel steel 1, are provided with a plurality of installation holes; a plurality of adjustable ground anchor mechanisms 7, and each adjustable ground anchor mechanism 7 passes through different installation holes to fix the channel steel 1 to the experimental ground; Two ball hinge spring bearings are fixedly connected to the two ends of the channel steel 1 respectively. The two ball hinge spring bearings all include a seat body 4, a snap ring 3 and a plurality of springs 19. One end of the seat body 4 is connected to the channel steel 1. Fixed connection, the other end of the seat body 4 is provided with a semicircu...

Embodiment 2

[0034] On the basis of Example 1, in order to prevent the experimental oil and gas pipeline 8 from being subjected to the impact load of the explosion, the ground anchor mechanism is not fixed firmly and the entire experimental device becomes loose, which affects the accuracy of the experimental data.

[0035] like figure 1 and 5 As shown, wherein, the adjustable ground anchor mechanism 7 includes a casing 18 and a screw 14, the casing 18 is fixedly connected with the channel steel 1 through the installation hole, and the hole of the casing 18 is provided with the Described screw rod 14 matches internal thread, and described screw rod 14 one end is inserted underground through sleeve pipe 18 pipe holes, and screw rod 14 is threadedly connected with sleeve pipe 18 pipe holes, and screw rod 14 other end is provided with knob 10.

[0036] like Figure 5 and 6As shown, wherein the adjustable ground anchor mechanism 7 also includes a pull rod 9, one end of the pull rod 9 is prov...

Embodiment 3

[0039] On the basis of Example 1, in order to reduce the impact of the explosion load on the base body 4 and prevent the base body 4 from being deformed by the impact, the deformation independence of the experimental oil and gas pipeline 8 is effectively ensured.

[0040] like image 3 and 4 As shown, wherein, the inner wall of the semicircular notch 5 of the seat body 4 and the inner wall of the clasp 3 are fixedly connected with a honeycomb energy-absorbing material layer 13, and each spring 19 passes through the honeycomb absorbing material at the end far away from the experimental oil and gas pipeline 8. The energy material layer 13 is fixedly connected with the inner wall of the semicircular notch 5 or the inner wall of the snap ring 3 .

[0041] The honeycomb energy-absorbing material layer 13 is inlaid on the inner wall of the semicircular notch 5 of the seat body 4 and the inner wall of the clasp 3 , and the honeycomb energy-absorbing material layer 13 isolates the im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com