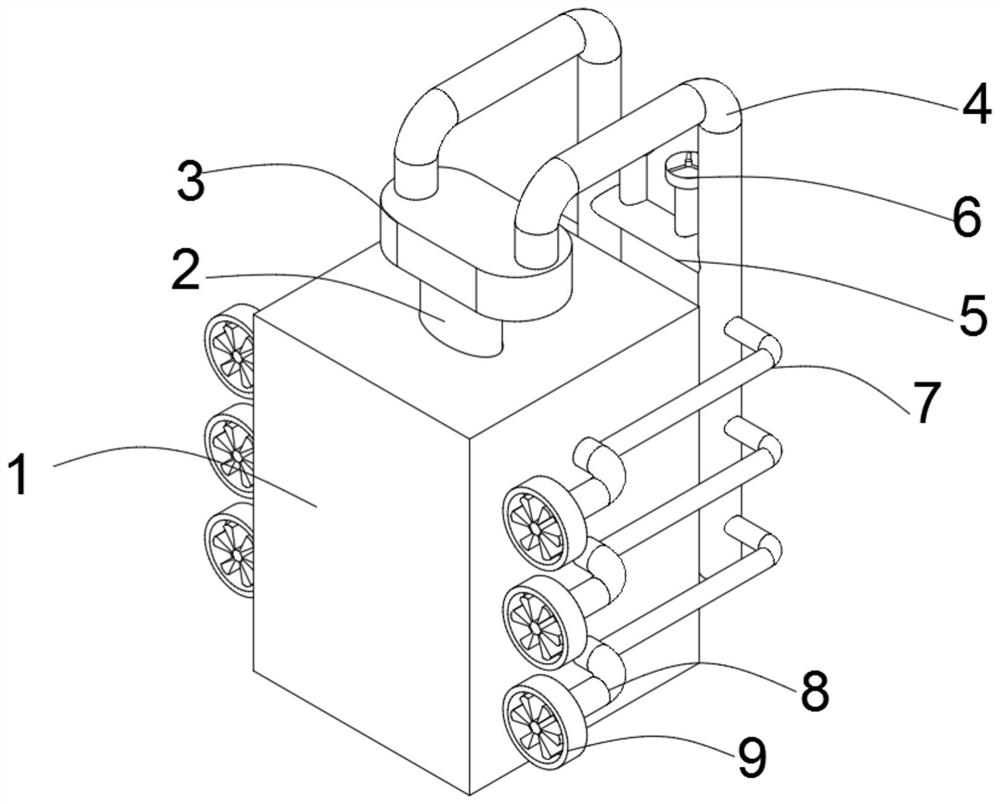

Agricultural power mechanical device between rice fields

A technology for power machinery and agriculture, applied in the field of agricultural power machinery in paddy fields, can solve the problems of single structure, inflexibility, easy to be blocked by mud and water, low efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

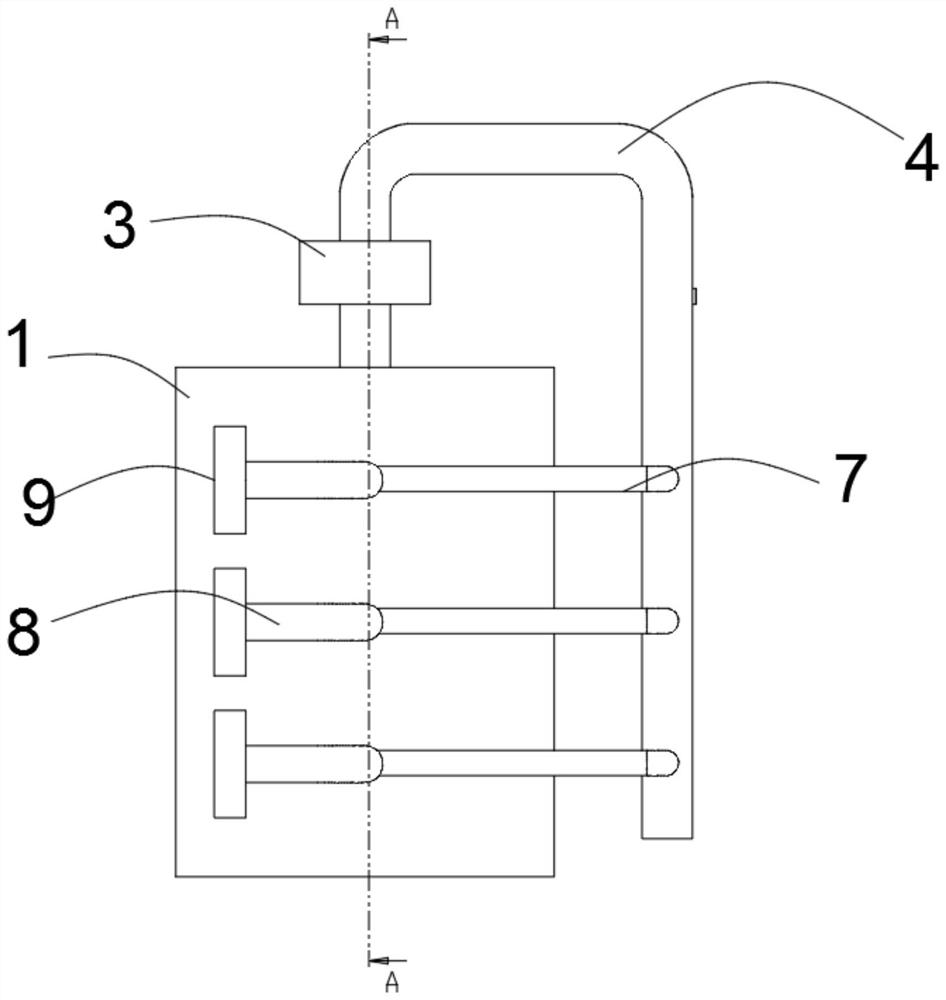

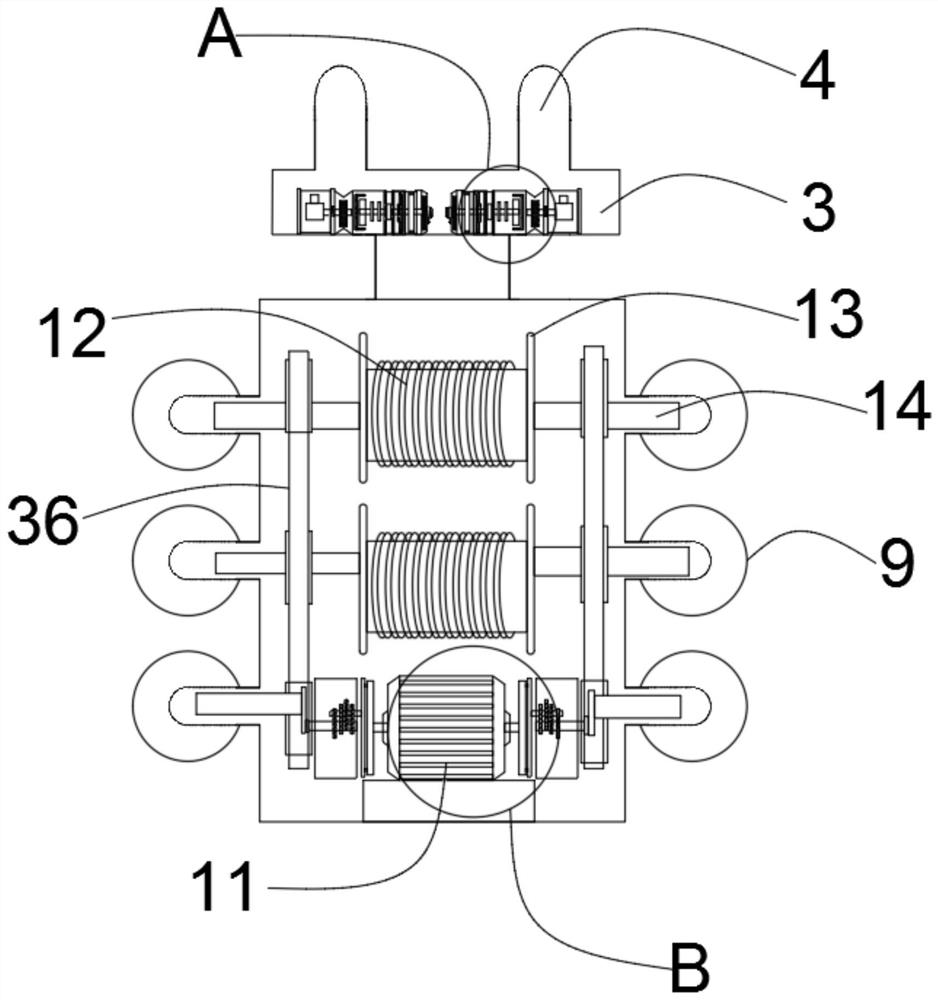

[0040] This embodiment is a method of using agricultural power machinery in rice fields: first, connect the power supply box 1 with the machinery that needs power supply, open the adjustable air pressure switch 15, and the air is under the action of the booster fan impeller 17 Carry out the first pressurization, and then through the speed-up gear box 19, further increase the air pressure, send the pressurized gas to the adjustable air filter 26, and output it to the pressurization pipe 4 through the pressurized airflow pipe 27, Turn on the pressurized air flow switch 6 and send it to the power turbine 9 for further pressurization to complete the provision of the first power.

Embodiment 2

[0042] It needs to be further explained that: in addition to the first power provided, there is also the second power provided by the motor 11. When the motor 11 rotates, the rotating shaft 29 also starts to rotate. According to the required power demand, through the adjustable speed torque gear Group 31, adjust its speed, the rotating shaft 29 drives the driven torque gear 32 to rotate, drives the power rotating shaft 14 to rotate, thereby drives the driving wheel 33 to start rotating, under the effect of the rotating belt 36, the first driven wheel 34 and the second The driven wheel 35 also starts to rotate, completing providing the second power for the power turbine 9 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com