Building shear wall formwork supporting structure and construction method

A formwork support and shear wall technology, which is applied in the field of house construction, can solve problems such as heavy weight, and achieve the effects of easy handling and use, convenient fixing, and stable support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

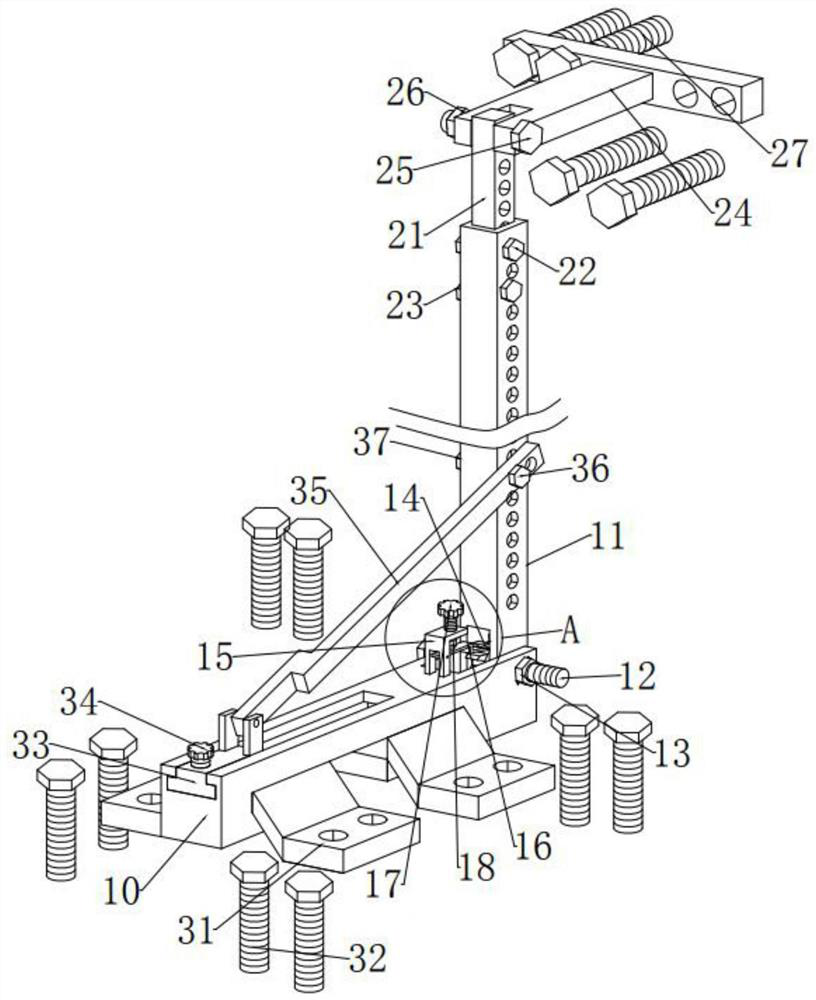

[0039] Embodiment: according to specification Figure 1-4 It can be seen that a construction method of a building shear wall formwork support structure comprises the following steps:

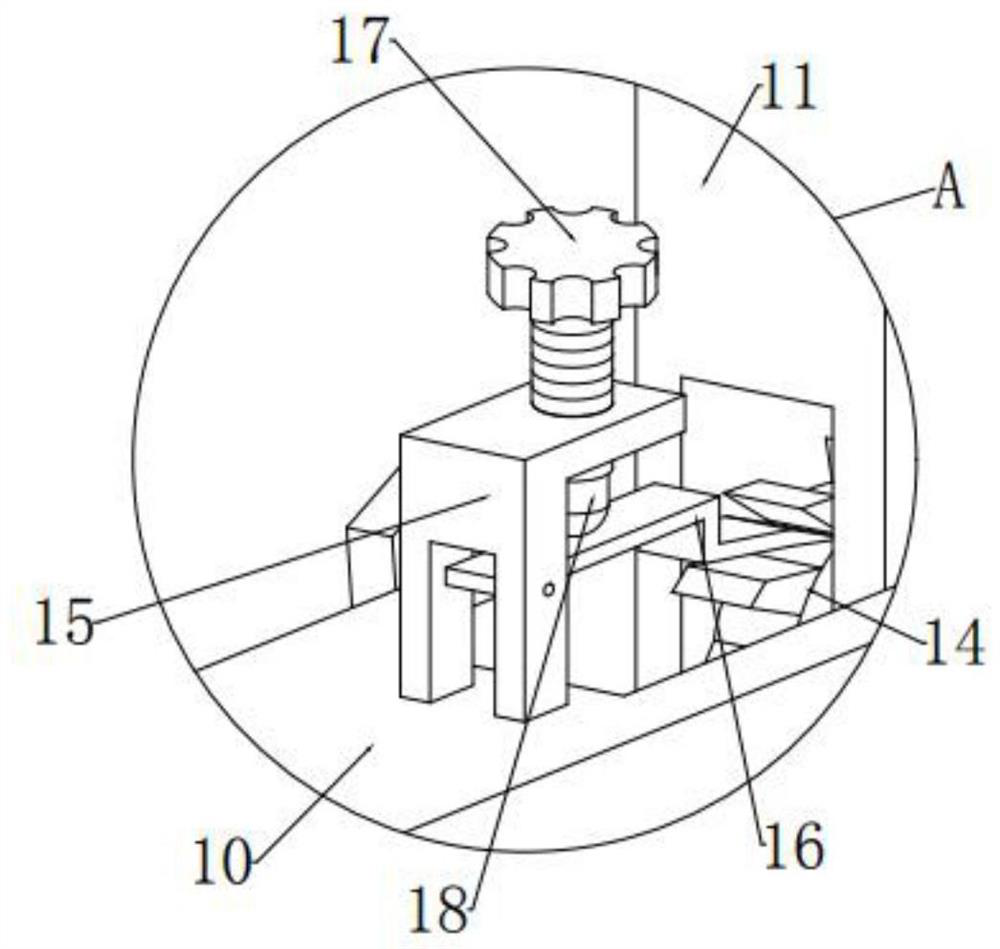

[0040] Step 1: first place the main body seat 10 in the main body structure 1 horizontally, firstly embed the ratchet 14 in the bottom end of the support seat 11, and connect the right end of the main body seat 10 with the help of the shaft 12 and then use the first nut 13 to realize Fix the limit, and then pass the fixed plate in the fixed structure 3 through the main body seat 10 to fix the fixed plate on the ground with the help of the second fastening bolt 32, so that the main body is limited and fixed;

[0041] Step 2: According to the requirement of the support angle, the support seat 11 can be moved clockwise, so that it can be turned over on the main body seat 10 by means of the shaft 12. At the same time, the ratchet wheel 14 will move the pawl 16 to move clockwise in one direction, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com