Ground dry construction structure and construction method thereof

A dry method and ground technology, which is applied to floors, building structures, local raised floors, etc., can solve the problems of heavy pollution on the construction site, easy generation of large dust, and high labor costs, so as to shorten the construction period and reduce processing costs , the effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

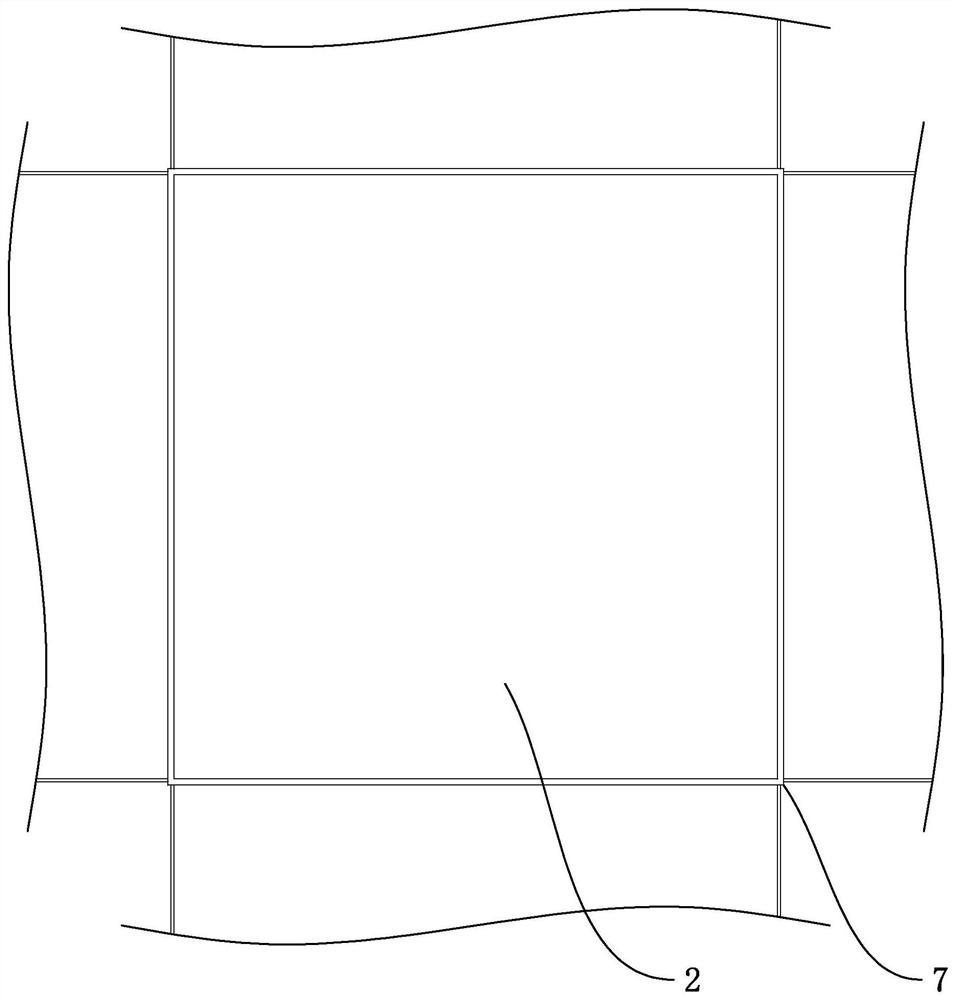

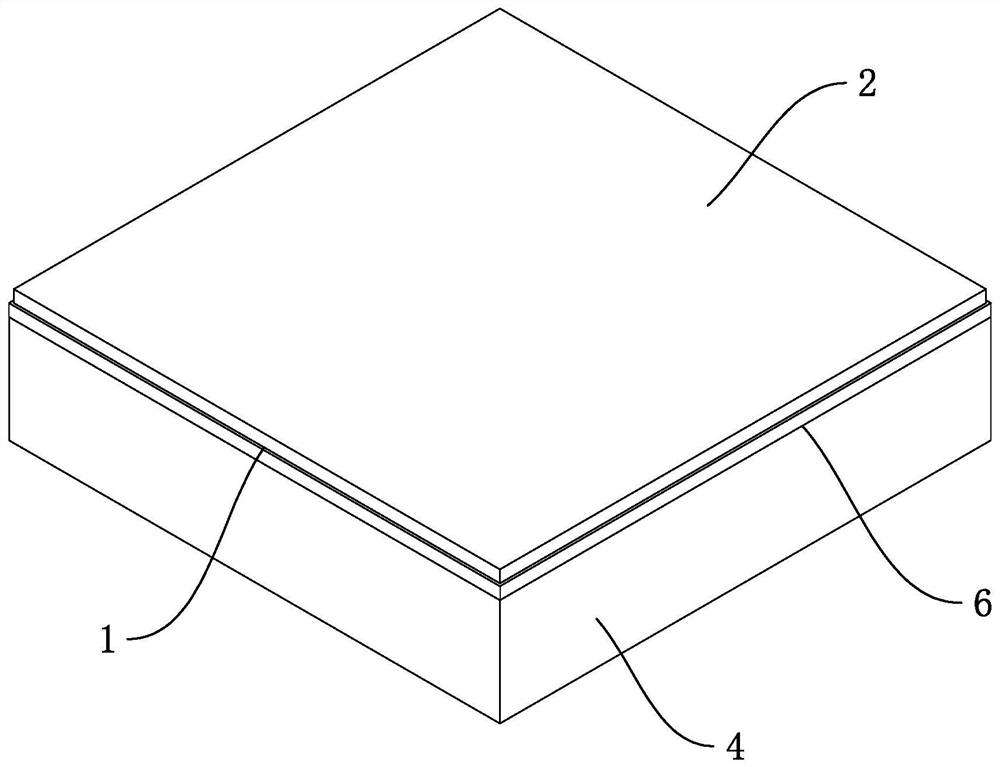

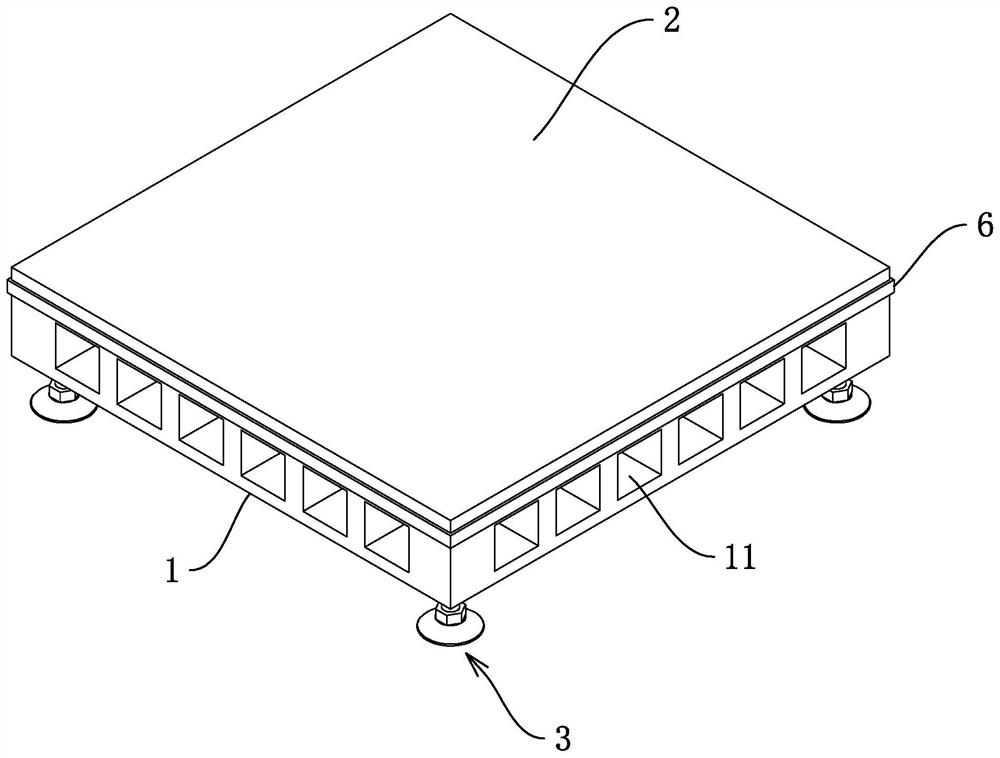

[0049] Such as figure 1 and figure 2 As shown, the ground dry construction structure includes a support body 1 and a panel layer 2 . Wherein, the panel layer 2 corresponds to the support body 1 one by one, the orthographic projections of the panel layer 2 and the support body 1 are equal, and the panel layer 2 is positioned and installed on the support body 1 . The supporting body 1 is laid on the structural base layer, and then foaming glue is injected between the panel layer 2 and the structural base layer. connected and fixed to form a floor structure laid on the structural base.

[0050] Through the foam rubber layer 4, the panel layer 2 is stably fixed on the structural base, and the formed floor structure can play the role of thermal insulation and sound insulation; due to the dry construction, it can shorten the construction period, effectively reduce the processing cost, and reduce the construction process. pollution of the environment.

[0051] Such as figure 2...

Embodiment 2

[0065] Such as Figure 7 and Figure 8 As shown, the difference between this embodiment and Embodiment 1 is that due to the principle of thermal expansion and contraction, usually, a certain gap should be reserved between the panel layers 2. In order to ensure the aesthetics of the floor laying, it is necessary to The gaps between adjacent panel layers 2 are made substantially equal. Each side of the support body 1 is fitted with at least two plug-in boards 5, and each side of the support body 1 is provided with a plug-in hole 13 corresponding to the plug-in boards 5, and the plug-in boards 5 are connected to the adjacent supports. The body 1 is plugged and fitted to ensure equal gaps between adjacent panel layers 2 .

[0066] continue as Figure 7 and Figure 8 As shown, in this embodiment, the plug board 5 is a plate-like structure made of plastic injection molding, and both ends of the plug board 5 are formed with plug parts that are mated with the support body 1, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com