Lattice beam structure and construction method thereof

A construction method and technology of lattice beams, which are applied in basic structure engineering, excavation, construction, etc., can solve the problems of long working hours and construction difficulties, and achieve the effects of reducing quantity, improving construction efficiency, and increasing connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The following is attached Figure 1-6 The application is described in further detail.

[0043] The embodiment of the present application discloses a lattice beam structure.

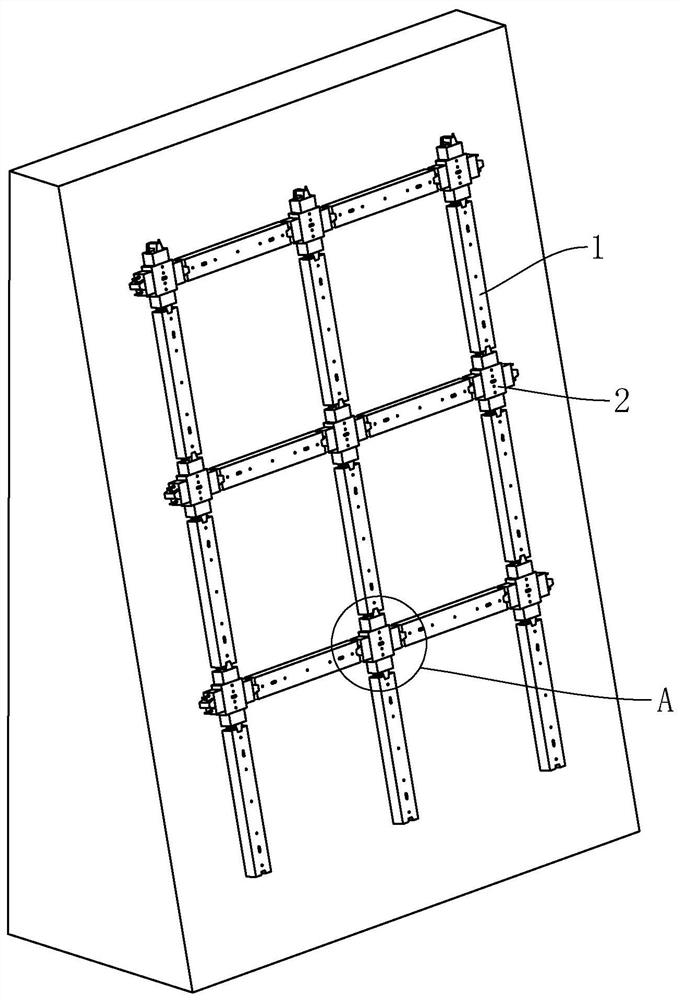

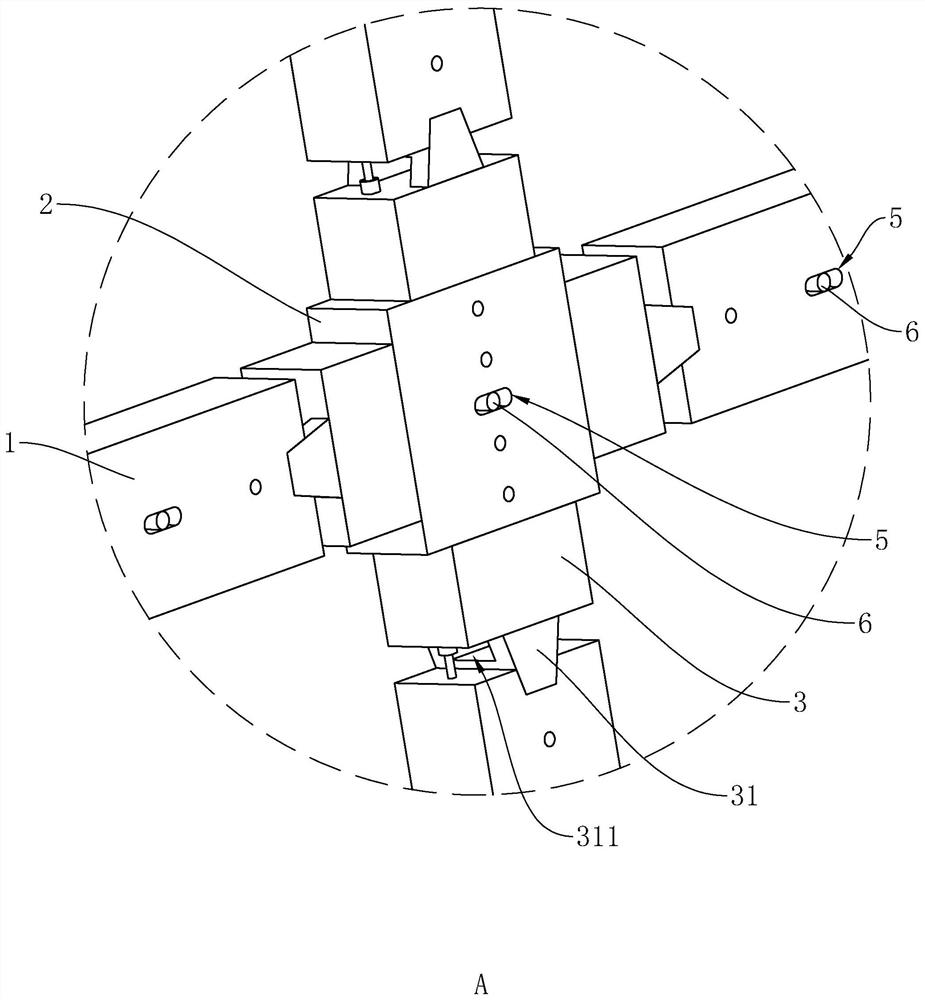

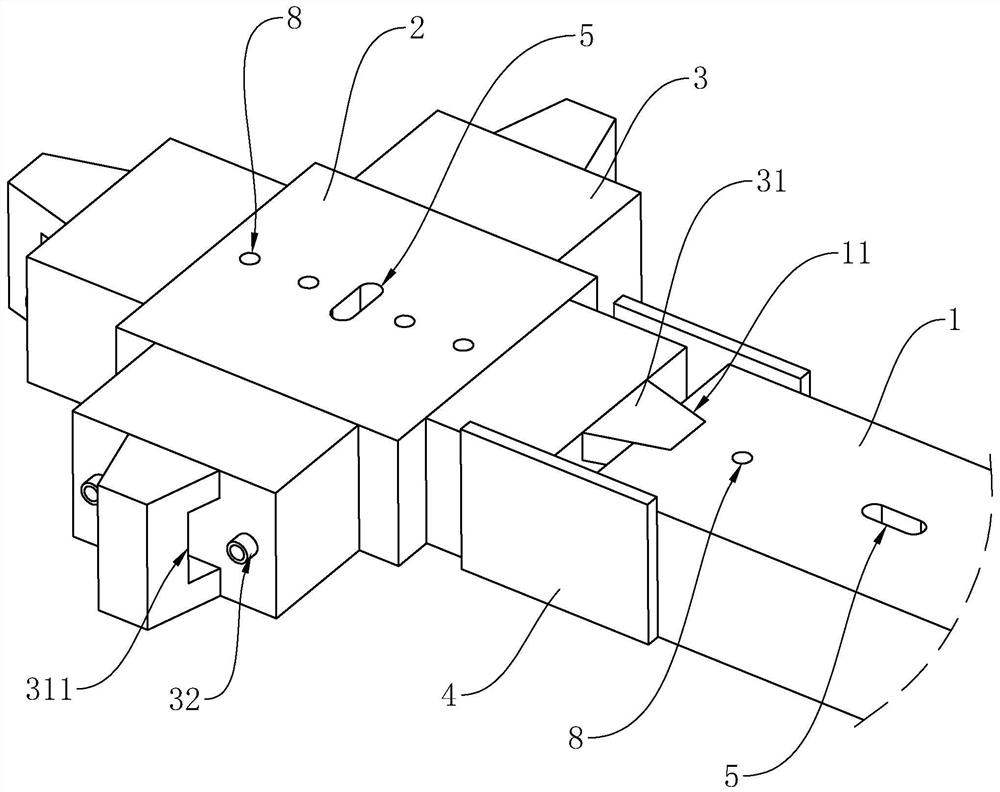

[0044] refer to figure 1 and figure 2 , the lattice beam structure includes a plurality of prefabricated beams 1 and a plurality of prefabricated nodes 2, both ends of each prefabricated beam 1 are connected to a prefabricated node 2, and each prefabricated node 2 is connected to a plurality of prefabricated beams 1, so that Prefabricated beams 1 and prefabricated nodes 2 form a grid. Both prefabricated nodes 2 and prefabricated beams 1 are prefabricated with reinforced concrete. When constructing lattice beams on the slope, after the prefabricated prefabricated beams 1 and prefabricated nodes 2 are transported to the construction site, the prefabricated beams 1 and Node 2 is anchored on the slope, and then concrete is poured at the junction of precast beam 1 and precast node 2, so that precas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com