Roadbed earthwork reinforcing method for highway engineering

A highway and earthwork technology, applied in infrastructure engineering, roads, excavation, etc., can solve the problems of erosion, poor firmness and weather resistance, affecting the service life of highway subgrades, etc., and achieve the effect of improving weather resistance and firmness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

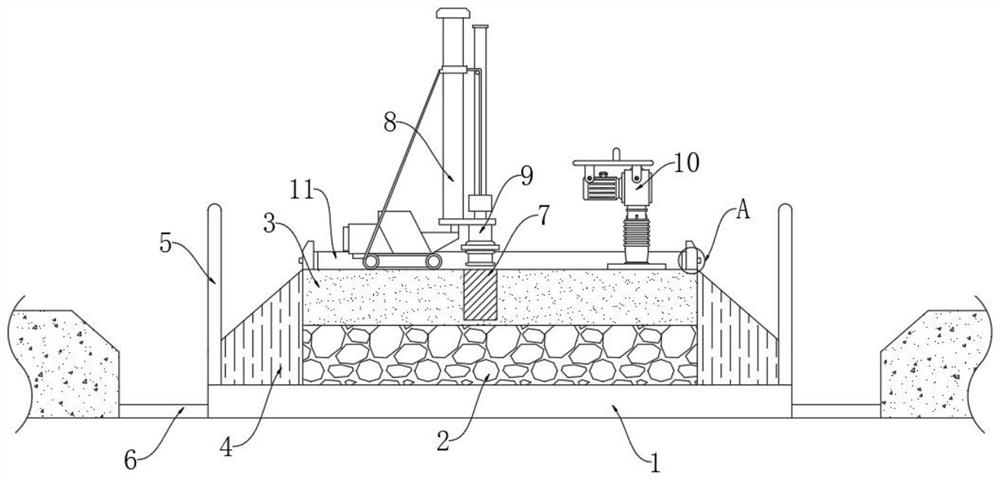

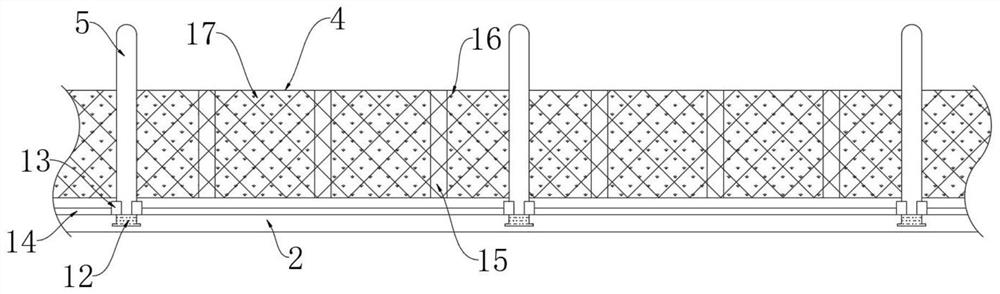

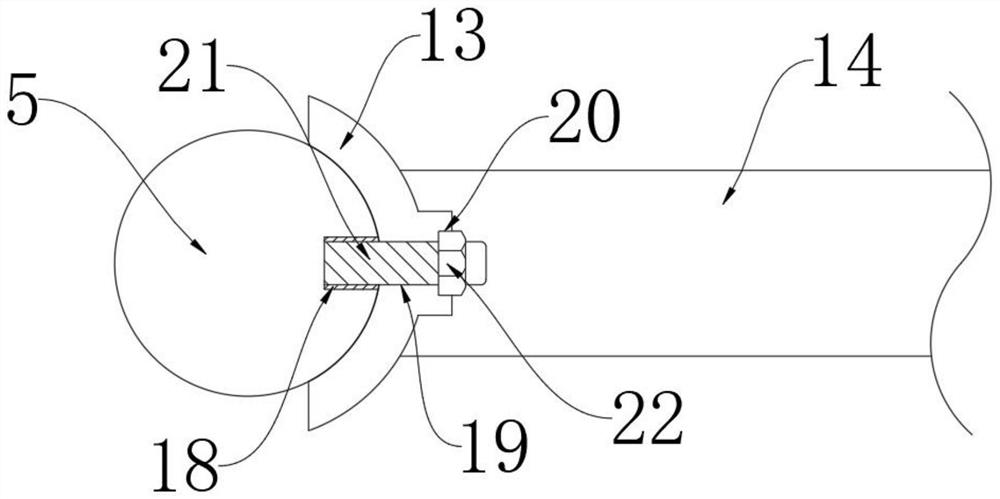

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings, so that those of ordinary skill in the art can implement it after referring to this specification.

[0033] Such as Figure 1-6 Shown, a kind of subgrade earthwork reinforcement method of expressway engineering, comprises the following steps:

[0034] Step 1: First lay the earth-rock mixed material evenly on the upper end of the subgrade platform. After the earth-rock laying is completed, cover the upper end of the laid earth-rock with clay, and then continue to lay the clay on both sides of the earth-rock laying position to form a reinforced earth-rock oblique wave structure;

[0035] Step 2: Use an accurate angle measuring instrument to form the ramp angle of the clay pavement into a 45-degree bevel, then pour concrete at the beginning and end of the ramp structure, and then install the grounding laterally on the outside of the ramp Pile, pre-excavate the pre-burie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com