Method for reinforcing soft soil foundation by taking industrial solid waste as main raw material

A technology for industrial solid waste and soft soil foundation, applied in soil protection, chemical instruments and methods, agriculture, etc., can solve problems such as difficulty in processing waste, inability to meet social needs, iron and steel plants, and a large amount of cement, so as to reduce the cost of reinforcement , The effect of improving the strength of the foundation and improving the strength of the soft soil foundation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to further describe the present invention, a method of strengthening soft soil foundation using industrial solid waste as the main raw material of the present invention will be further described in conjunction with the following examples. However, the present invention is not limited to the Examples.

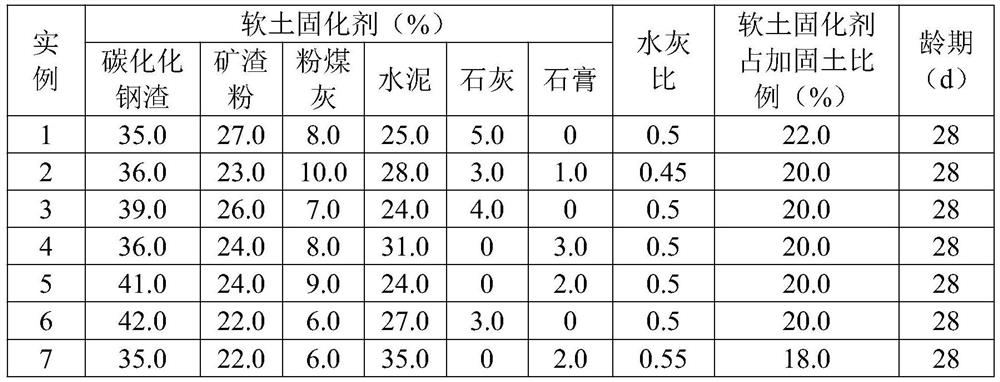

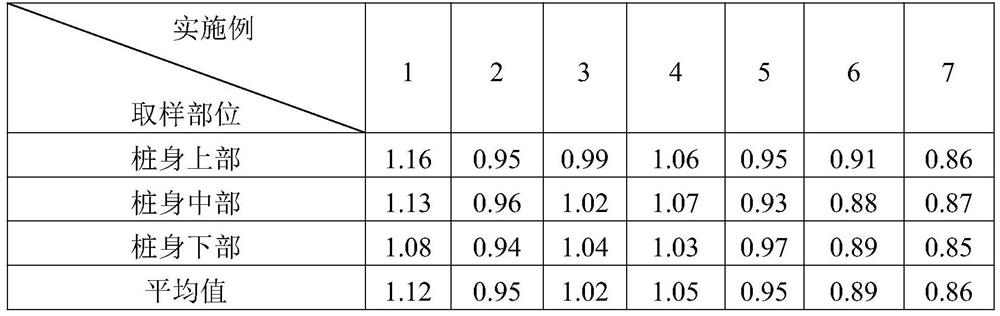

[0030] The mass percent content of each component in the soft soil solidifying agent raw material that the present invention adopts is: carbonated steel slag 35.0%~42.0%, slag powder 22.0%~27.0%, fly ash 6.0~10.0%, cement 24.0%~35.0% %, lime, gypsum or a mixture of the two in any proportion 2.0-5.0%. The particle size of the carbonated steel slag needs to be controlled, preferably below 2 mm, and the finer the particle size, the better the effect. The cement is 42.5 grade ordinary Portland cement. The soft soil curing agent is prepared with dry materials, and the soft soil curing agent slurry is prepared according to the water-cement ratio of 0.5. The carbonate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com