Stable pumping type slump retaining agent and preparation method thereof

A slump-retaining agent and pumping technology, which is applied in the field of building materials, can solve the problems of not meeting the needs of concrete construction well, prone to segregation, bleeding, and not fully satisfying cement, so as to achieve reasonable distribution of hydration products and enhanced Adsorption and retarding ability, delaying and reducing the effect of heat of hydration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The preparation method of the stable pumping type slump retaining agent of the present invention comprises the following steps:

[0034] (1) Add 17.6-19.1 parts of polyether alcohol head and 0.3-0.9 parts of catalyst into a high-pressure reactor equipped with a stirrer and a thermometer, and start vacuuming to gauge pressure (-0.085) ~ (-0.090) after nitrogen replacement for 3 times )MPa, then heat up to 110-115°C to start dehydration for 1-1.5h, cool down to 105°C and start to continuously feed 301.8-310.0 parts of cyclic monomers, control the pressure to less than 0.6MPa, and keep warm at 100-110°C for 2 -3h aging to negative pressure, cooling down and discharging to obtain polyether monomer with a molecular weight of about 2000.

[0035] (2) Add the polyether monomer prepared in step (1) into the reaction kettle, heat up to 45-50°C with a water bath; prepare A Liquid, 42.5-43.6 parts of ester substances, 0.5-1.0 parts of alcohol head, 2.1-5.4 parts of reducing agent...

Embodiment 1

[0037] A stable pumping type slump inhibitor is mainly composed of the following components, the total mass of raw materials is 1000 parts, and each component includes: 18.9 parts of poly-1,2-propylene glycol, 301.9 parts of ethylene oxide, 0.6 parts of aluminum lithium, 42.8 parts of diethyl acrylate, 4.3 parts of sodium formaldehyde sulfoxylate, 3.3 parts of di-tert-butyl peroxide, 1.9 parts of thioglycolic acid, 5.7 parts of triethanolamine, the rest is water, the total mass is 1000 parts.

[0038] The preparation method of the described stable pumping type slump retaining agent comprises the following steps:

[0039] (1) Add 17.9 parts of poly-1,2-propylene glycol and 0.6 parts of lithium aluminum hydride to a high-pressure reactor equipped with a stirrer and a thermometer, and start vacuuming to gauge pressure -0.085MPa after nitrogen replacement for 3 times, and then heat up to Start dehydration at 115°C for 1 hour, cool down to 105°C and start feeding 301.9 parts of eth...

Embodiment 2-6

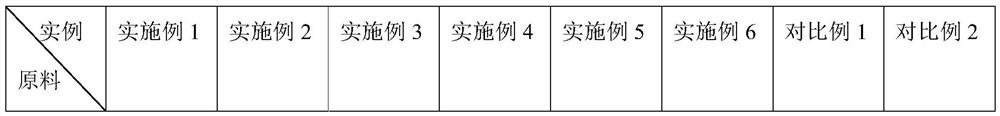

[0042] Concrete parameters (steps are the same) in the concrete raw material of embodiment 2-6 and preparation method are different from embodiment 1, specifically as shown in table 1 and table 2 below (table 1 is raw material, and table 2 is the preparation method in parameter), the representations not listed in table 2 are the same as in Example 1.

[0043] Table 1

[0044]

[0045]

[0046]

[0047] Table 2

[0048]

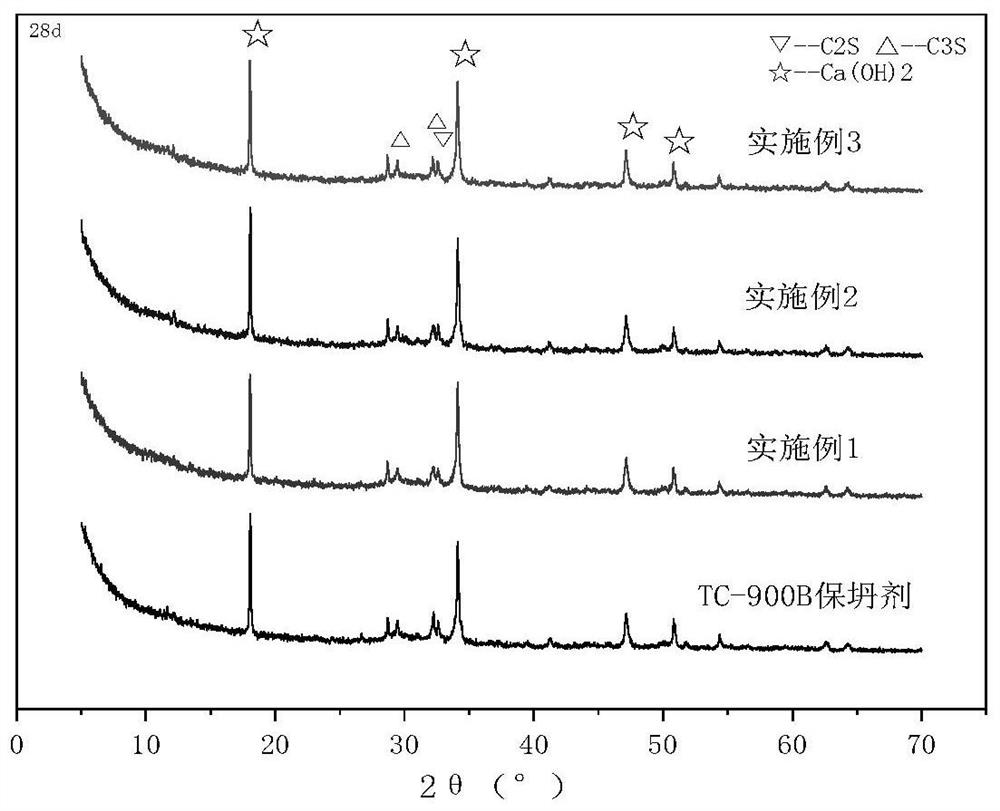

[0049] The product of the present invention and Hubei Tengchen TC-900B slump-retaining agent are made into C50 concrete samples, and the following table 3 is obtained through testing.

[0050] table 3

[0051]

[0052]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com