A kind of preparation method of polymer cement waterproof mortar

A waterproof mortar and polymer technology, which is applied to clay preparation devices, cement mixing devices, chemical instruments and methods, etc., can solve the problems of low mortar use efficiency, large investment, and low use value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

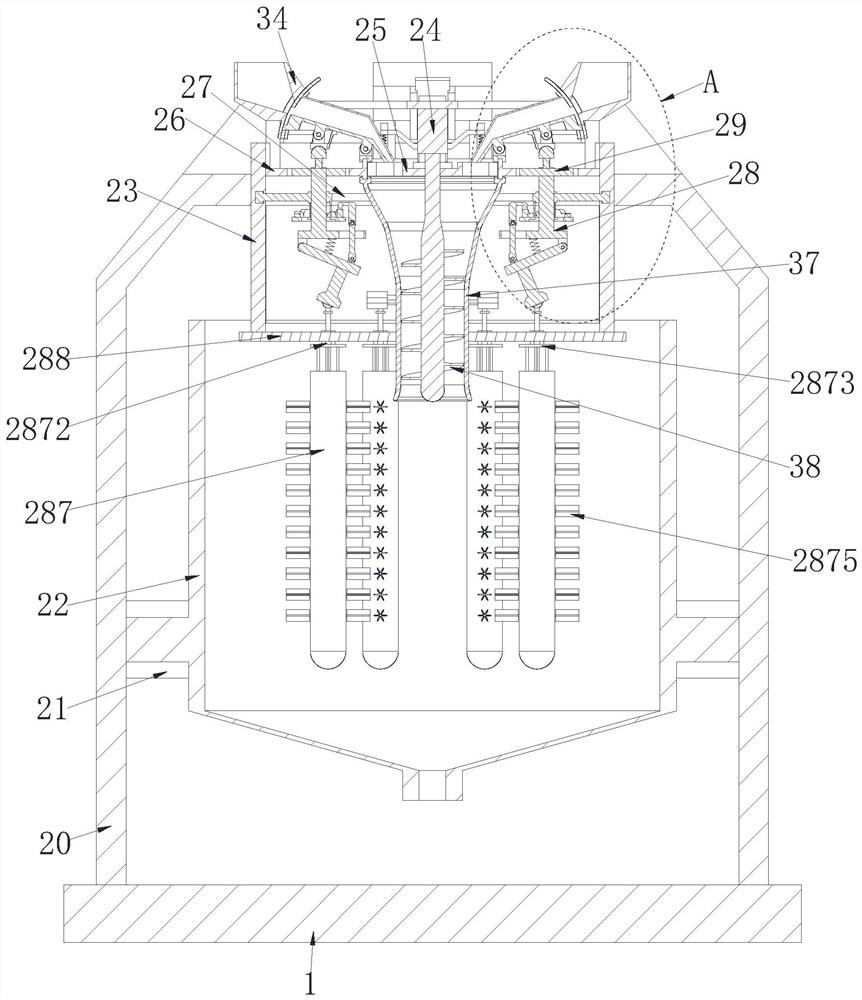

[0033] In order to make the technical means, creation features, achievement goals and effects realized by the present invention easy to understand and understand, the following combination Figure 1 to Figure 7 , the present invention will be further described.

[0034] A polymer cement waterproof mortar preparation method, which uses a polymer cement waterproof mortar preparation equipment, the polymer cement waterproof mortar preparation equipment comprises a base 1, a stirring device 2 and a feeding device 3, using the above polymer cement waterproof mortar The concrete method for preparing polymer cement waterproof mortar by mortar preparation equipment is as follows:

[0035] Step 1. Preparatory work: debug the polymer cement waterproof mortar preparation equipment;

[0036]Step 2. Preparation of mortar raw materials: Since the polymer cement waterproof mortar is made of cement and fine aggregate as the main material, high molecular polymer as the modified material, wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com