Process for treating high-salt and high-concentration organic wastewater

A technology for organic wastewater treatment and organic wastewater, applied in water/sewage treatment, water treatment parameter control, biological water/sewage treatment, etc., can solve the problems of reduced wastewater treatment volume, reduced solid salt quality, and reduced processing difficulty, achieving The effect of reducing the amount of treatment, reducing the amount of use, and reducing the difficulty of treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

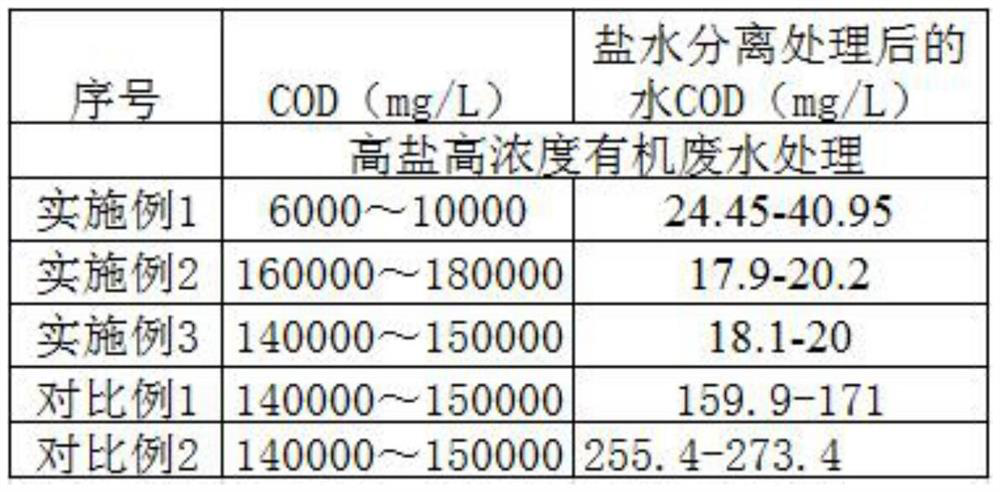

Embodiment 1

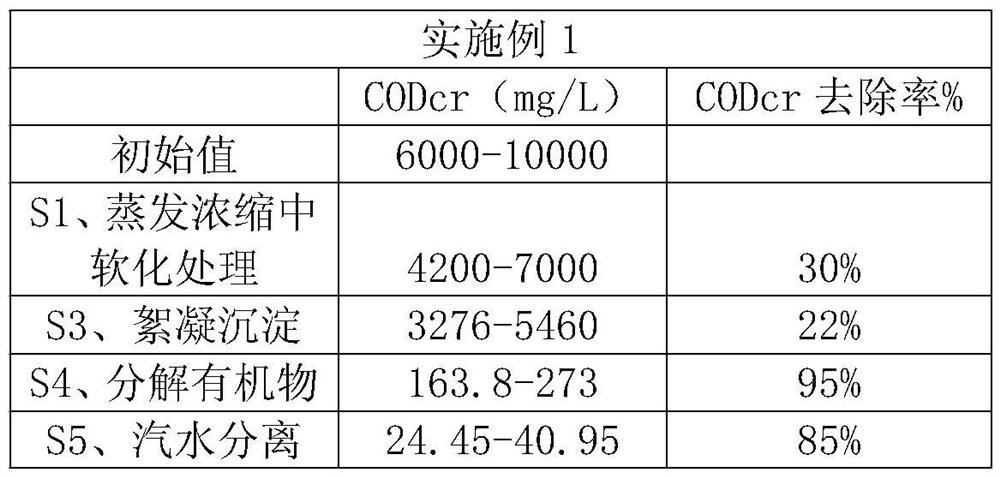

[0047] A high-salt high-concentration organic wastewater treatment process, comprising the following steps:

[0048] S1. Evaporation and concentration: After softening the high-salt and high-concentration organic wastewater, use a three-effect evaporator for evaporation treatment to obtain steam and wastewater concentrate; the COD of the high-salt and high-concentration organic wastewater Cr The concentration is 6000-10000mg / L.

[0049] S2. Regulating PH: introducing the concentrated wastewater obtained in S1 into an acid-base pool to adjust the pH of the wastewater;

[0050] S3, flocculation and precipitation: send the wastewater in the acid-base pool to the flocculation and sedimentation tank for treatment, and add a composite flocculant;

[0051] The sediments in the flocculation sedimentation tank and the acid-base tank in S2 and S3 are sent to the sludge concentration tank, and the sludge is dehydrated and processed into mud cake for disposal.

[0052] S4. Decomposing o...

Embodiment 2

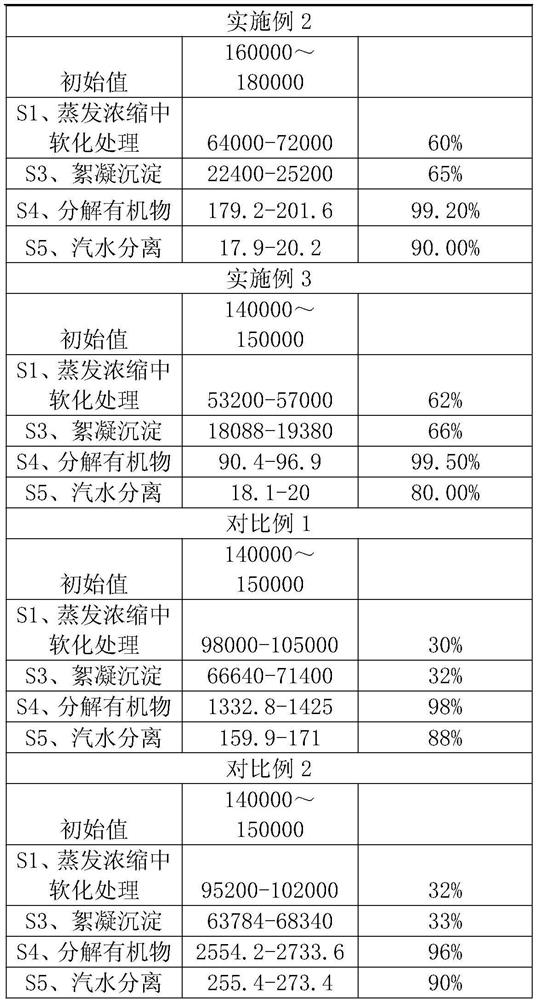

[0061] A high-salt high-concentration organic wastewater treatment process, comprising the following steps:

[0062] S1. Evaporation and concentration: After softening the high-salt and high-concentration organic wastewater, use a three-effect evaporator for evaporation treatment to obtain steam and wastewater concentrate; the COD of the high-salt and high-concentration organic wastewater Cr The concentration is 160000-180000mg / L.

[0063] S2. Regulating PH: introducing the concentrated wastewater obtained in S1 into an acid-base pool to adjust the pH of the wastewater;

[0064] S3, flocculation and precipitation: send the wastewater in the acid-base pool to the flocculation and sedimentation tank for treatment, and add a composite flocculant;

[0065] The sediments in the flocculation sedimentation tank and the acid-base tank in S2 and S3 are sent to the sludge concentration tank, and the sludge is dehydrated and processed into mud cake for disposal.

[0066] S4. Decomposin...

Embodiment 3

[0075] A high-salt high-concentration organic wastewater treatment process, comprising the following steps:

[0076] S1. Evaporation and concentration: After softening the high-salt and high-concentration organic wastewater, use a three-effect evaporator for evaporation treatment to obtain steam and wastewater concentrate; the COD of the high-salt and high-concentration organic wastewater Cr The concentration is 140000~150000mg / L.

[0077] S2. Regulating PH: introducing the concentrated wastewater obtained in S1 into an acid-base pool to adjust the pH of the wastewater;

[0078] S3, flocculation and precipitation: send the wastewater in the acid-base pool to the flocculation and sedimentation tank for treatment, and add a composite flocculant;

[0079] The sediments in the flocculation sedimentation tank and the acid-base tank in S2 and S3 are sent to the sludge concentration tank, and the sludge is dehydrated and processed into mud cake for disposal.

[0080] S4. Decomposin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com