Extremely-simple Bayer process

A technology of Bayer method and sintering method, which is applied in the direction of alumina/hydroxide, etc., can solve the problems of alumina recovery rate, alkali consumption not as good as that of factories with sintering method, limited use, and low investment, so as to reduce sintering Manufacturing cost, production cost reduction, and the effect of reducing system flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited by the embodiments.

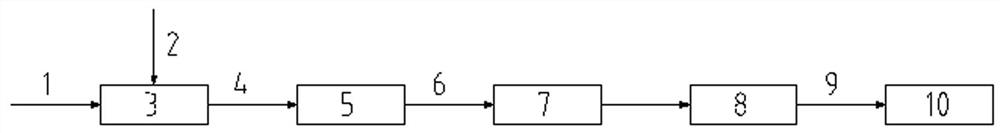

[0015] As shown in the figure, the minimalist Bayer method of the present invention includes the following steps: bauxite 1 and lime 3 enter the raw material mill 2, and the obtained qualified pulp 4 enters the dissolution 5 process, and the dissolved slurry 6 enters the diluted tank 7 and then enters The settling tank 8 is washed, and the obtained Bayer red mud 9 is sent to the sintering method 10 for treatment.

[0016] In the step of entering the raw material mill 2, the quantity of the raw material mill 2 is reduced, so that the particle size of the qualified pulp becomes larger, and the particle size of the qualified pulp 4 is subject to the sintering method 10 system.

[0017] In the 2nd step of entering the raw material mill, reduce the amount of lime 2, reduce the load of lime ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com