Chip capacitor packaging device

A chip capacitor and electrical connection technology, applied in packaging, transportation packaging, packaging protection, etc., can solve the problems of vacancies, filling vacancies, and inability to retreat in winding tapes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0033] It is worth noting that the orientation words such as "up" and "down" involved in this article are all determined relative to the perspective of the drawings, and are only for the convenience of description, and cannot be understood as limitations on the technical solution.

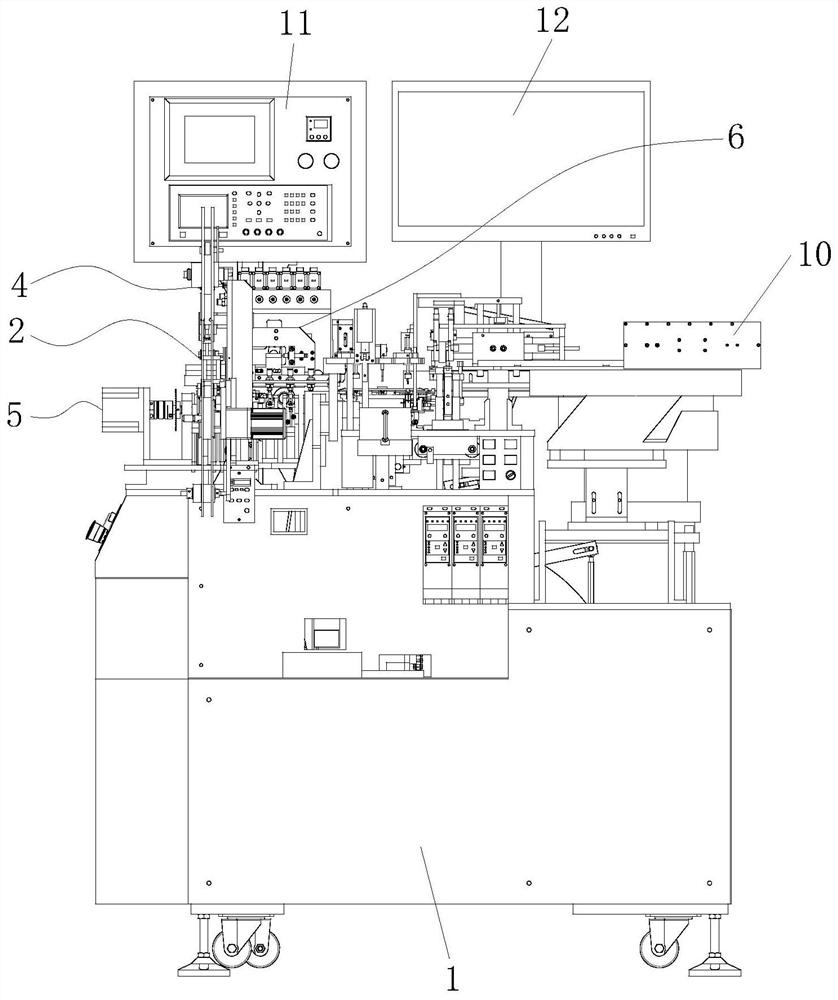

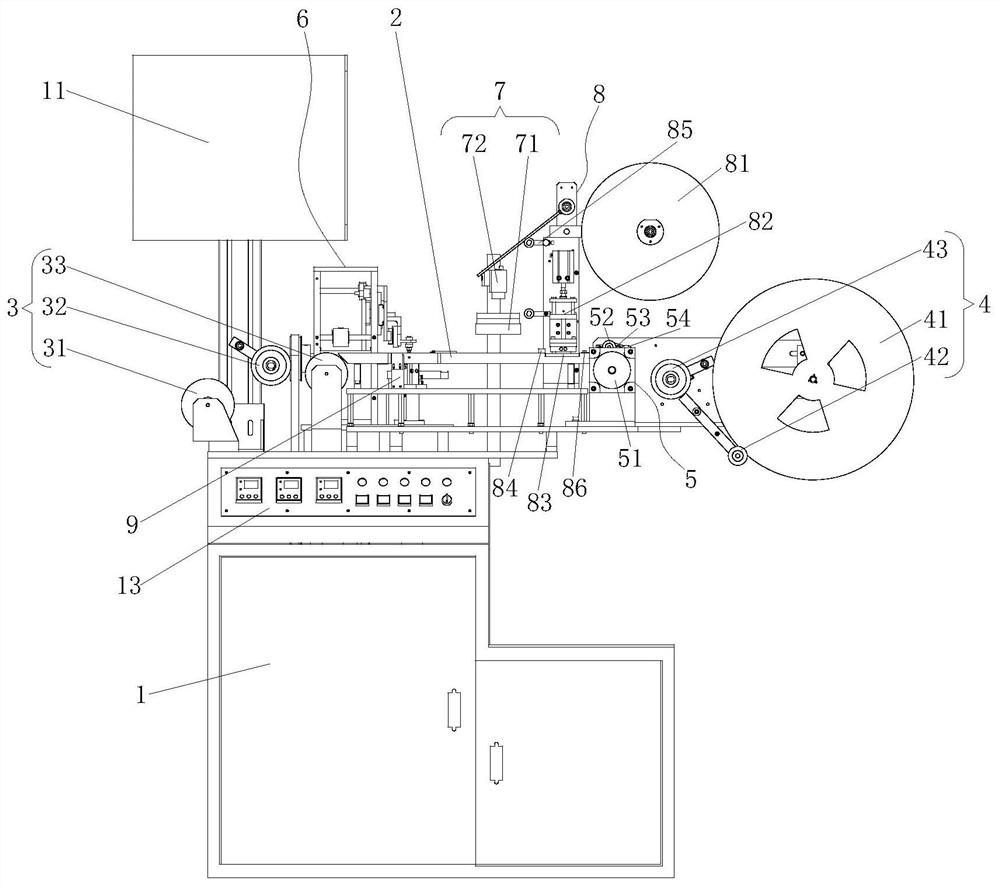

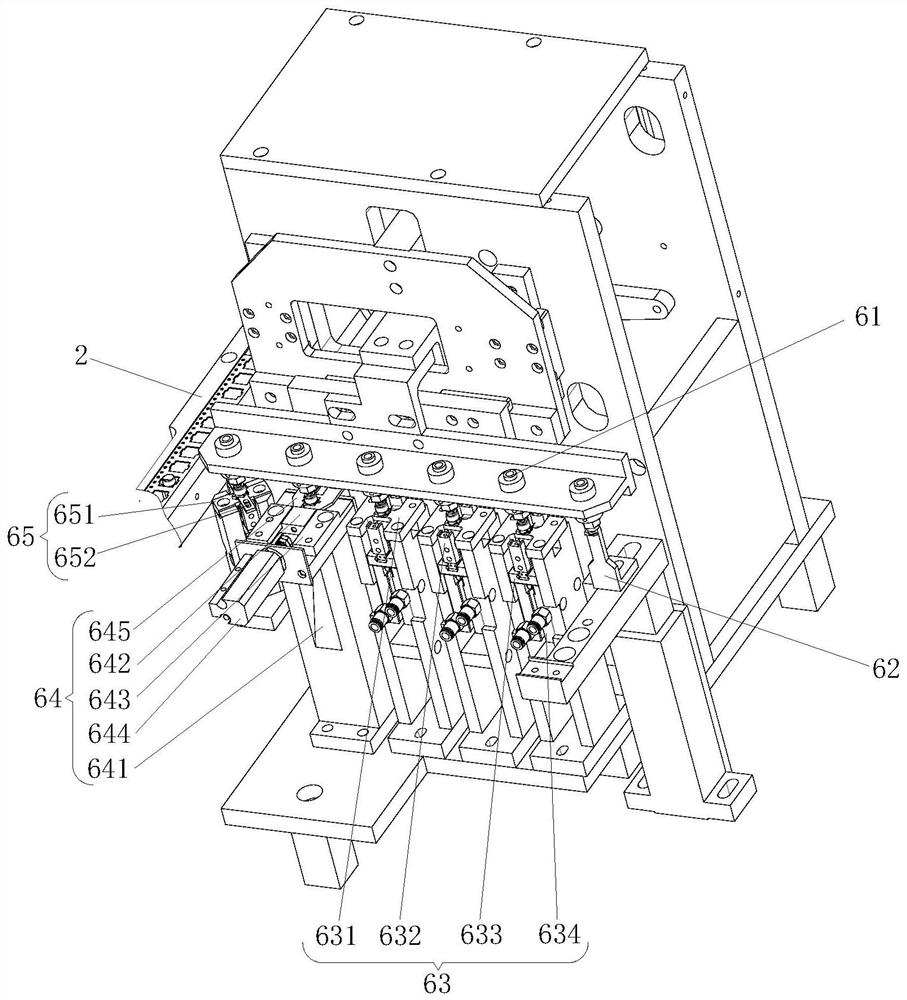

[0034] Such as Figure 1 ~ Figure 3As shown, a chip capacitor packaging device includes a console 1, a control system is provided in the console 1, and the control system is electrically connected to a leakage short circuit tester 11, a display screen 12 and an electric control switch 13, and the leakage short circuit tester 11 is arranged on the top of the console 1, and the existing leakage short-circuit tester 11 can be used to set it up, so as to detect and ensure that the product meets the quality requirements; 13 is located on one side of the console 1, the console ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com