Laser welding method for aircraft engine exhaust pipe end flange

An aircraft engine, laser welding technology, applied in laser welding equipment, welding equipment, tubular objects, etc., can solve the problems of poor service reliability and low exhaust pipe accuracy, achieve convenient assembly, reduce welding deformation, and reliable butt welding Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

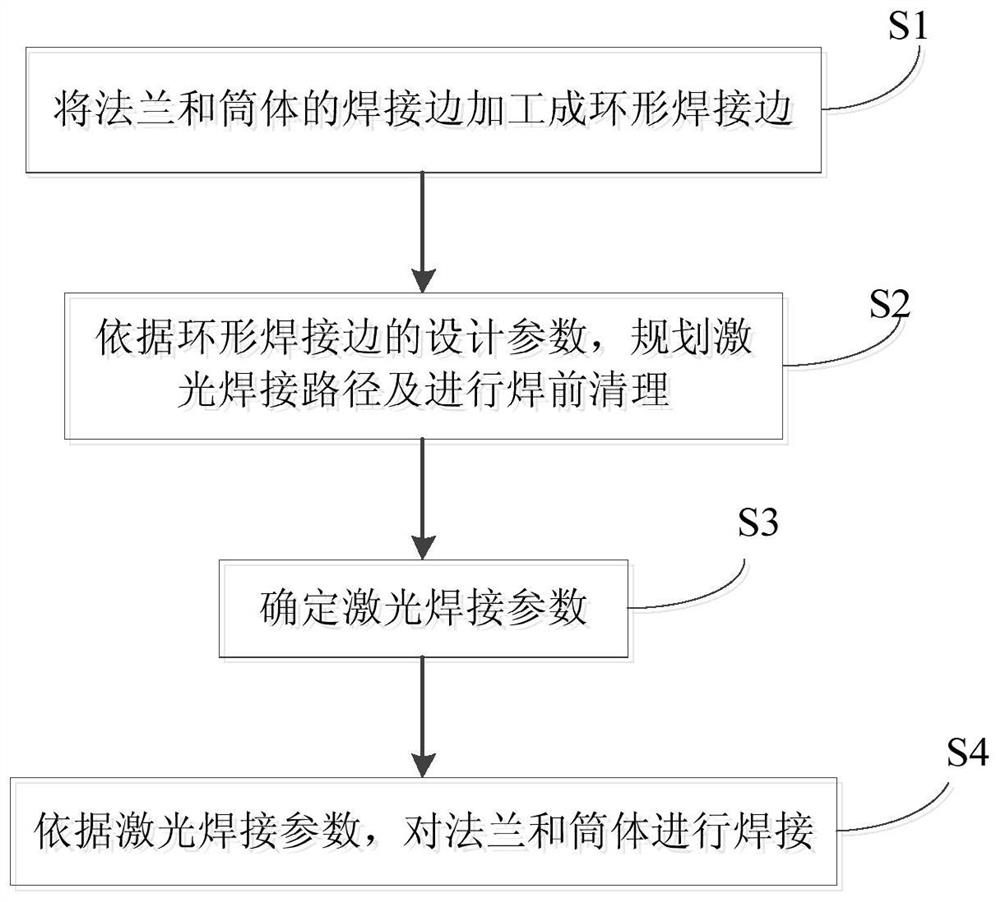

[0084] An aircraft engine exhaust pipe is made of 0Cr18Ni9 stainless steel, the initial welding edge of the flange is 5mm, and the welding edge of the cylinder is 1mm. The technical solution of the present invention is used to realize the laser welding of the end flange, which mainly includes the following steps:

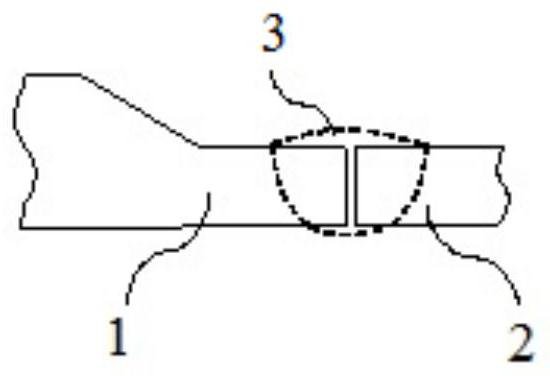

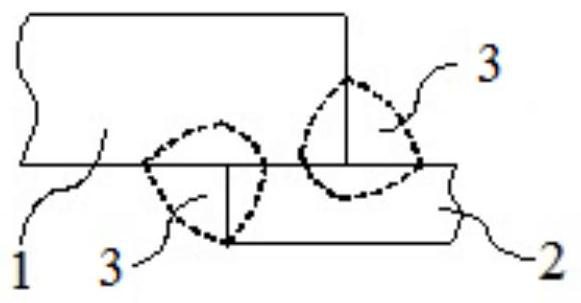

[0085] Step 1: Process flange 1 and cylinder 2 annular welding edges. The welding edge of flange 1 is based on the inner wall of the exhaust pipe, processed to a wall thickness of δ = 3mm, the length of the δ wall thickness state is L = 5mm, and an annular groove is prepared on the inner side of the welding edge of flange 1 to match the cylinder body 2 The welded edge forms a plug-in assembly; the depth a of the annular groove is a=0.5mm, and the radial height of the annular groove is consistent with the wall thickness of the cylinder 2, that is, 1mm. After the flange 1 and the welding edge of the cylinder 2 are assembled, the inner surface between the two is basica...

Embodiment 2

[0091] An aircraft engine exhaust pipe is made of 0Cr18Ni9 stainless steel, the initial welding edge of the flange is 5mm, and the welding edge of the cylinder is 1mm. The technical solution of the present invention is used to realize the laser welding of the end flange, which mainly includes the following steps:

[0092] Step 1: Process flange 1 and cylinder 2 annular welding edges. The welding edge of flange 1 is based on the inner wall of the exhaust pipe, processed to a wall thickness of δ = 3mm, the length of the δ wall thickness state is L = 5mm, and an annular groove is prepared on the inner side of the welding edge of flange 1 to match the cylinder body 2 The welded edge forms a plug-in assembly; the depth a of the annular groove is a=0.5mm, and the radial height of the annular groove is consistent with the wall thickness of the cylinder 2, that is, 1mm. After the flange 1 and the welding edge of the cylinder 2 are assembled, the inner surface between the two is basica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com