Solid waste treatment device for lighting lamp manufacturing

A technology for solid waste and lighting fixtures, which is applied in grain processing, solid separation, and the use of liquid separating agents. It can solve the problems of different sizes of broken particles, no secondary crushing, and a large amount of dust, and achieves simple structure and reliable operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

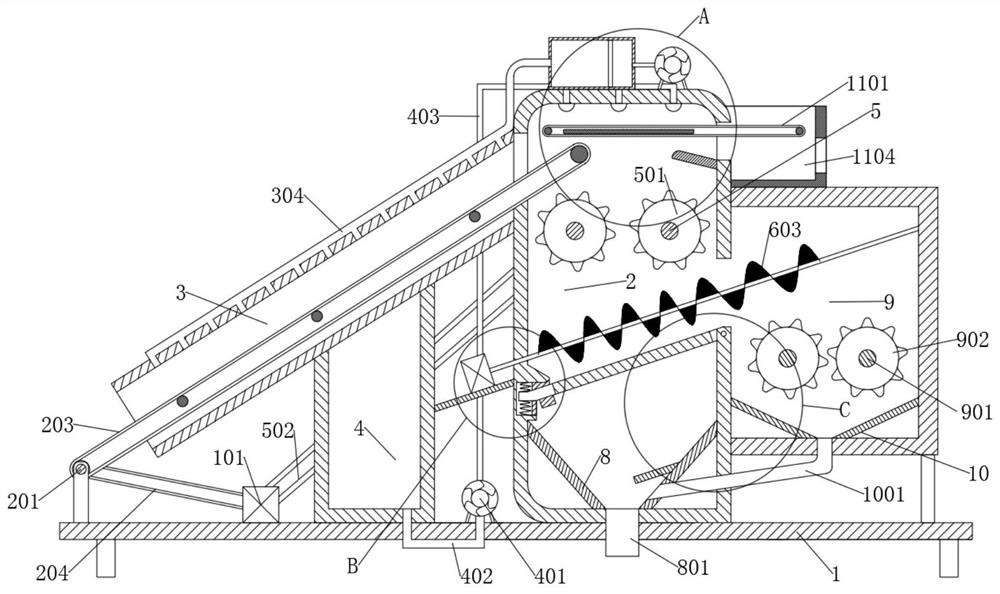

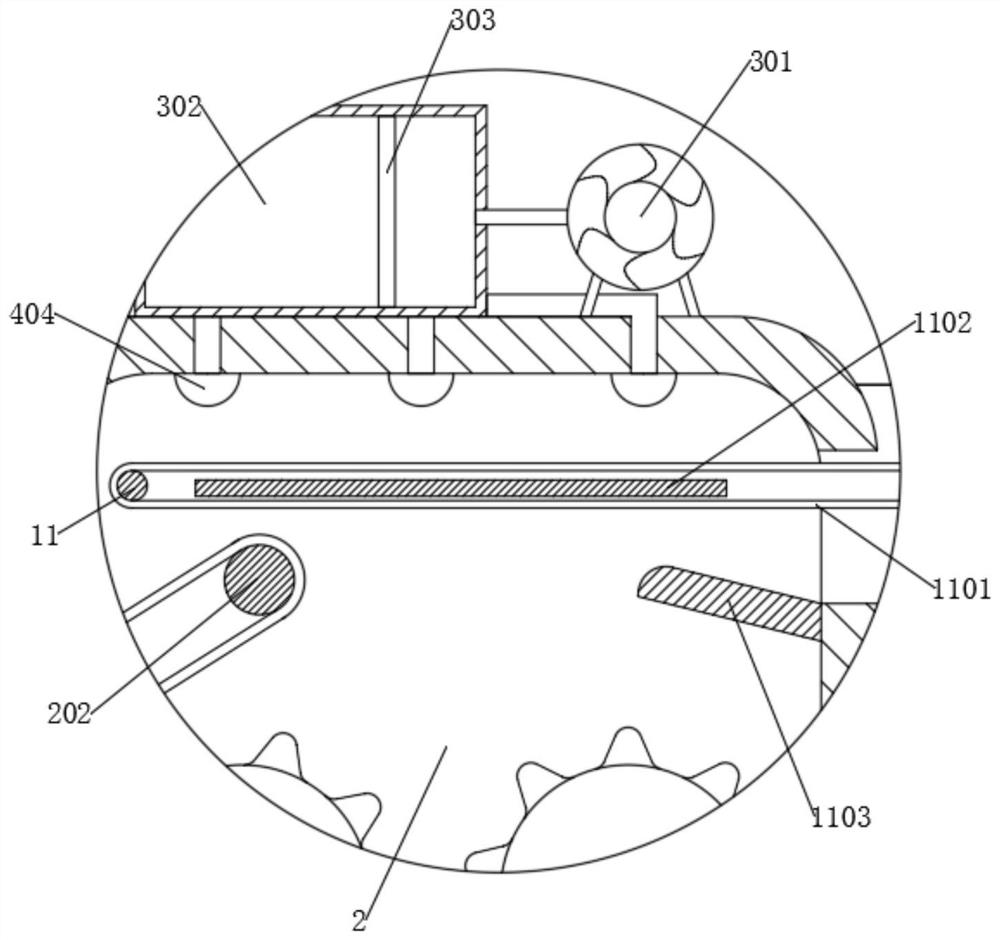

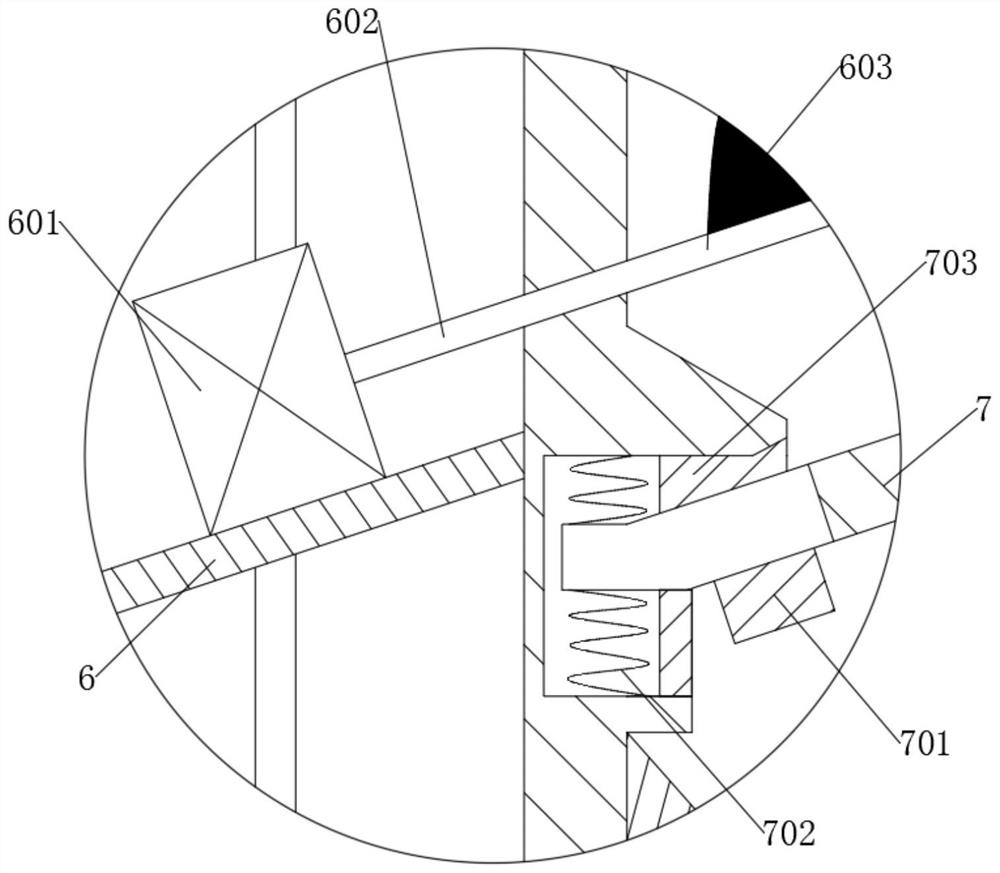

[0031] refer to Figure 1-5 , a solid waste treatment device for the manufacture of lighting fixtures, comprising a bottom plate 1 and a first crushing tank 2, the first crushing tank 2 is located on the bottom plate 1, a feeding mechanism is provided on the side wall of the first crushing tank 2, and a dust removal mechanism is set on the feeding mechanism cylinder 3, a dust removal mechanism is provided on the dust removal cylinder 3, a first crushing mechanism is provided in the first crushing tank 2, a second crushing tank 9 is provided on the bottom plate 1, and a There is a transmission mechanism, the side wall of the first crushing tank 2 is rotatably connected to the second filter plate 7, the bottom of the second filter plate 7 is provided with a vibrator 701, the bottom of the first crushing tank 2 is provided with a discharge port 801, and the second crushing tank 9 A second crushing mechanism is provided inside, and the bottom of the second crushing tank 9 communic...

Embodiment 2

[0043] refer to Figure 1-5 , a solid waste treatment device for the manufacture of lighting fixtures, comprising a bottom plate 1 and a first crushing tank 2, the first crushing tank 2 is located on the bottom plate 1, a feeding mechanism is provided on the side wall of the first crushing tank 2, and a dust removal mechanism is set on the feeding mechanism cylinder 3, a dust removal mechanism is provided on the dust removal cylinder 3, a first crushing mechanism is provided in the first crushing tank 2, a second crushing tank 9 is provided on the bottom plate 1, and a There is a transmission mechanism, the side wall of the first crushing tank 2 is rotatably connected to the second filter plate 7, the bottom of the second filter plate 7 is provided with a vibrator 701, the bottom of the first crushing tank 2 is provided with a discharge port 801, and the second crushing tank 9 A second crushing mechanism is provided inside, and the bottom of the second crushing tank 9 communic...

Embodiment 3

[0055] refer to Figure 1-5 , a solid waste treatment device for the manufacture of lighting fixtures, comprising a bottom plate 1 and a first crushing tank 2, the first crushing tank 2 is located on the bottom plate 1, a feeding mechanism is provided on the side wall of the first crushing tank 2, and a dust removal mechanism is set on the feeding mechanism cylinder 3, a dust removal mechanism is provided on the dust removal cylinder 3, a first crushing mechanism is provided in the first crushing tank 2, a second crushing tank 9 is provided on the bottom plate 1, and a There is a transmission mechanism, the side wall of the first crushing tank 2 is rotatably connected to the second filter plate 7, the bottom of the second filter plate 7 is provided with a vibrator 701, the bottom of the first crushing tank 2 is provided with a discharge port 801, and the second crushing tank 9 A second crushing mechanism is provided inside, and the bottom of the second crushing tank 9 communic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com