Test tube shaking and mixing device for hematology department examination

A test tube and blood technology, which is applied in the field of test tube shaking and mixing devices for hematology testing, can solve the problems of low work efficiency and high labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

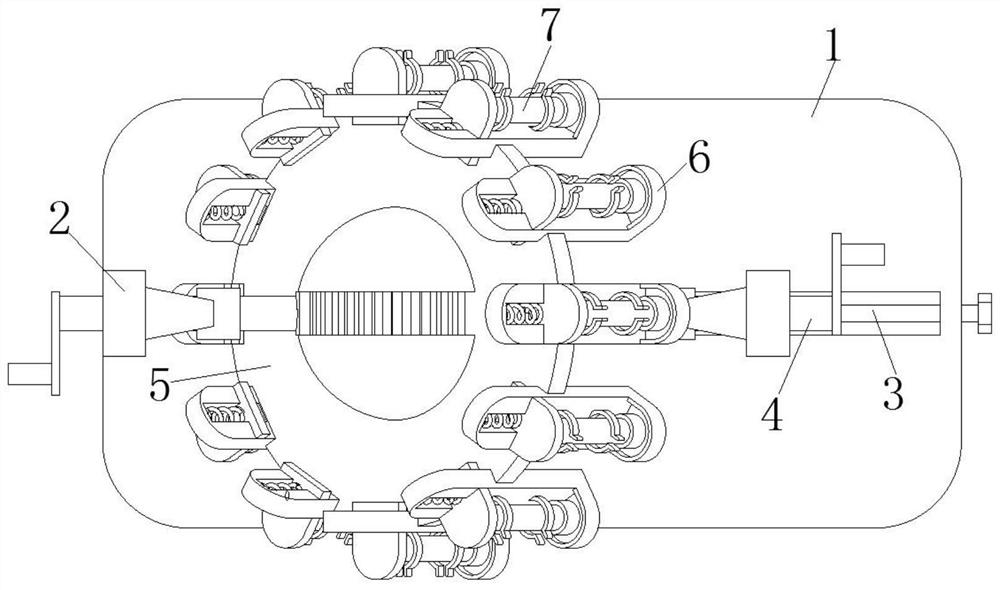

[0038] The use status of this embodiment is as Figure 8 As shown, rotating the threaded rod 3 drives one of the supporting rods 2 to move, and secondly, the supporting part 5 is clamped at the position between the two relative rotating parts 4. When clamping, the supporting disc 502 is perpendicular to the bottom plate 1. It is placed between two relative rotating parts 4 to ensure that the center of the sphere 501 coincides with the axis of the rotating shaft 401, and then the rotating threaded rod 3 drives the support rod 2 to move and then drives one of the rotating parts 4 to move to clamp the supporting part 5 Connected to the position between the two relative rotating parts 4, ensure that the first rack 403 on the sphere 501 is engaged with the second rack 504 that is fixedly connected to the inner surface of the arc plate 402 when clamping. After the overall fixation is completed, Move the extruding part 602 to shrink the compression spring 604, and the test tube 7 tha...

Embodiment 2

[0040] The use status of this embodiment is as figure 1 As shown, rotating the threaded rod 3 drives one of the supporting rods 2 to move, and secondly, the supporting part 5 is clamped at the position between the two relative rotating parts 4. When clamping, the supporting disc 502 and the bottom plate 1 form a certain angle. The position state is placed between the relative two rotating parts 4, and the angle range formed by the support disc 502 and the base plate 1 is 50°-140°. In this embodiment, the angle formed by the support disc 502 and the base plate 1 is 50°, ensure that the ball center of the sphere 501 coincides with the axis of the rotating shaft 401 when clamping, and then rotate the threaded rod 3 to drive the support rod 2 to move, and then drive one of the rotating parts 4 to move, and the supporting part 5 is clamped on the relative two rotating shafts. The position between the parts 4, ensure that the first rack 403 on the sphere 501 is engaged with the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com