Test bench for fretting abrasion of double-strand aluminum lead

A technology of fretting wear and aluminum wires, applied in the direction of applying repetitive force/pulsation force to test material strength, test wear resistance, etc., can solve problems such as not seen, and achieve the effect of reducing the impact of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

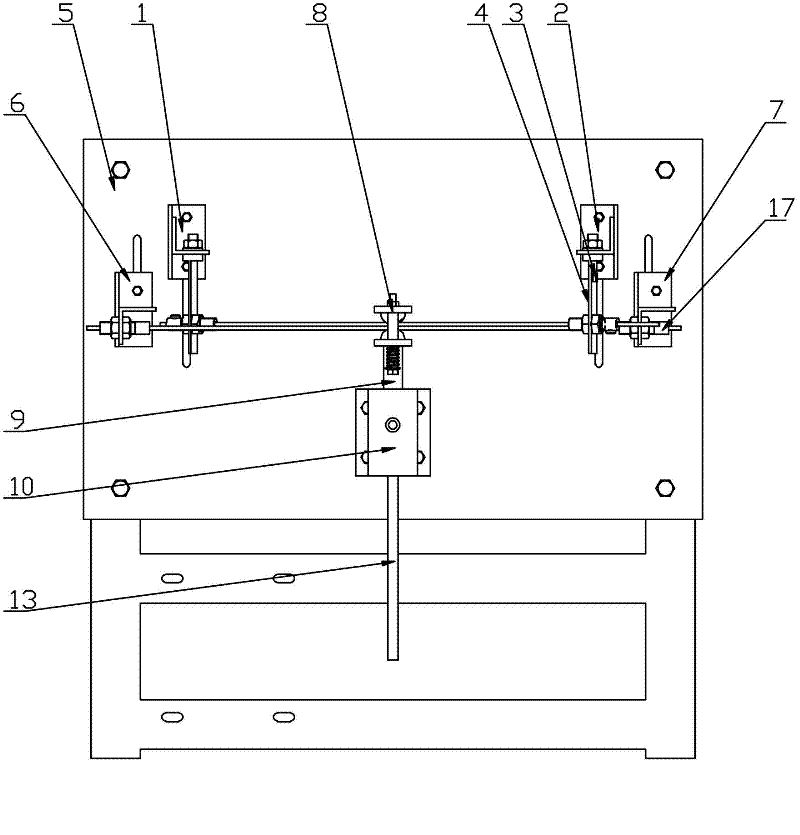

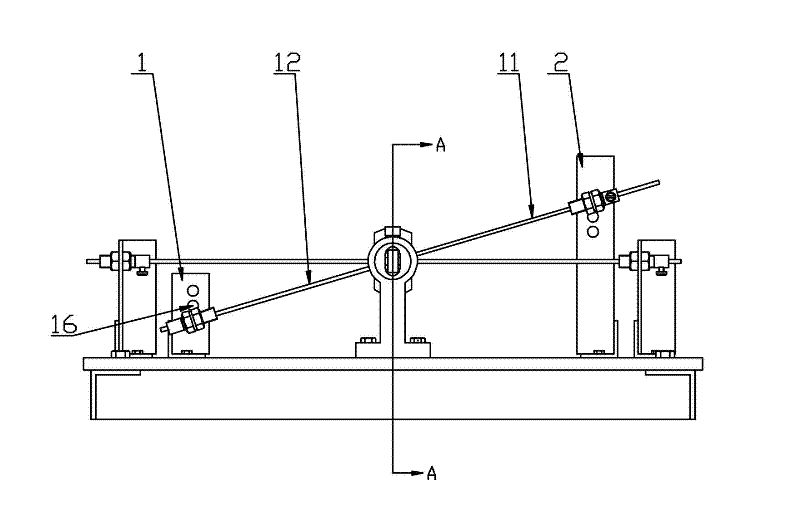

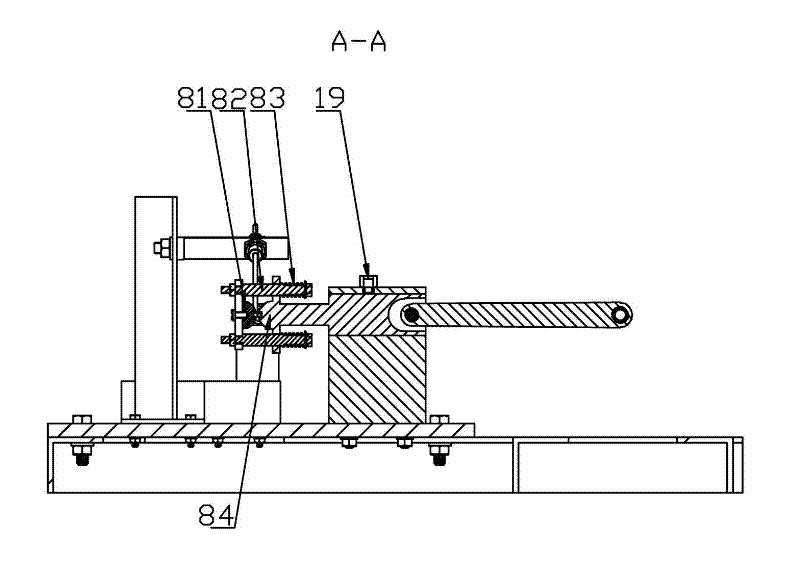

[0035] A double-strand aluminum wire fretting wear test bench, including a seat plate 5, a plurality of slots are arranged on the seat plate 5, a first lead frame 1, a second lead frame 2, a third lead frame 6 and a fourth lead frame 7 is installed on the seat plate 5 through slot holes, and the distance between the first wire 11 and the second wire 12 can be changed by changing the positions of the first wire frame 1, the second wire frame 2, the third wire frame 6 and the fourth wire frame 7. angle of wrapping. The first lead frame 1 and the second lead frame 2 are mounted on the seat plate 5 in pairs, and in order to obtain an inclination angle, the heights of the two are usually different. The first lead frame 1 and the second lead frame 2 are provided with a swivel joint 4, and one end of the swivel joint 4 is provided with a threaded joint 17, and one end of the swivel joint 4 is cylindrical, and is connected with the lead frame by threads, so that it can be adapted to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com