Refrigeration under-pressure sample gas separation method

A separation method and sample gas technology, which is applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problem of unreliable and thorough automatic gas-liquid separation, automatic gas-liquid separation, and refrigeration temperature adjustment, etc. problem, to achieve the effect of simple and reliable gas-liquid separation process, automatic separation of gas-liquid without levers, and improvement of heat conduction capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

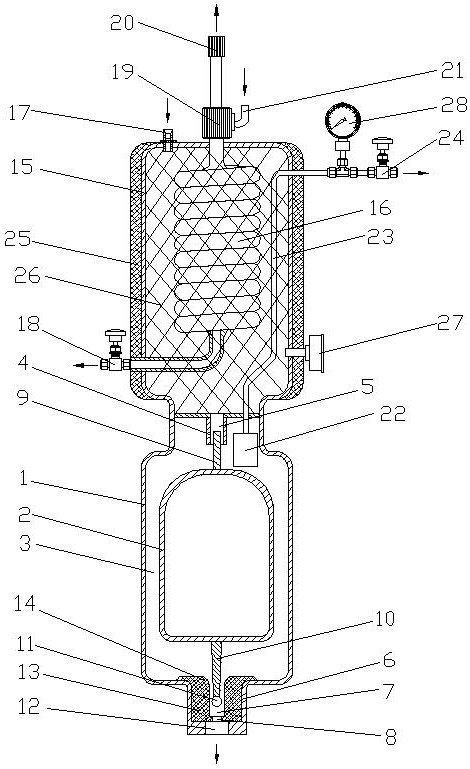

[0041] see figure 1 , a kind of refrigerated pressure sample gas separation method, comprises the following steps:

[0042] a. First pass the compressed gas into the vortex refrigerator 19 of the vortex refrigeration liquid discharge valve, then throttling and expanding the stainless steel bellows 16 to lower the temperature twice, and adjust the venting volume of the compressed gas through the first needle valve 18;

[0043] b. Control the refrigeration temperature of the compressed gas by adjusting the discharge volume of the first needle valve 18, control the sample gas output volume by adjusting the third needle valve 24, control the throttling expansion effect of the sample gas in the refrigeration stainless steel cylinder 15 and control the refrigeration stainless steel cylinder 15 The inner stainless steel wire mesh 26 obtains the cooling temperature of the compressed gas in the stainless steel bellows 16 through heat conduction, so that the cooling temperature of the c...

Embodiment 2

[0047] see figure 1 , a kind of refrigerated pressure sample gas separation method, comprises the following steps:

[0048] a. First pass the compressed gas into the vortex refrigerator 19 of the vortex refrigeration liquid discharge valve, then throttling and expanding the stainless steel bellows 16 to lower the temperature twice, and adjust the venting volume of the compressed gas through the first needle valve 18;

[0049] b. Control the refrigeration temperature of the compressed gas by adjusting the discharge volume of the first needle valve 18, control the sample gas output volume by adjusting the third needle valve 24, control the throttling expansion effect of the sample gas in the refrigeration stainless steel cylinder 15 and control the refrigeration stainless steel cylinder 15 The inner stainless steel wire mesh 26 obtains the cooling temperature of the compressed gas in the stainless steel bellows 16 through heat conduction, so that the cooling temperature of the c...

Embodiment 3

[0056] see figure 1 , a kind of refrigerated pressure sample gas separation method, comprises the following steps:

[0057] a. First pass the compressed gas into the vortex refrigerator 19 of the vortex refrigeration liquid discharge valve, then throttling and expanding the stainless steel bellows 16 to lower the temperature twice, and adjust the venting volume of the compressed gas through the first needle valve 18;

[0058] b. Control the refrigeration temperature of the compressed gas by adjusting the discharge volume of the first needle valve 18, control the sample gas output volume by adjusting the third needle valve 24, control the throttling expansion effect of the sample gas in the refrigeration stainless steel cylinder 15 and control the refrigeration stainless steel cylinder 15 The inner stainless steel wire mesh 26 obtains the cooling temperature of the compressed gas in the stainless steel bellows 16 through heat conduction, so that the cooling temperature of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com