Great-load self-adaptive automatic speed control system capable of quickly shifting gears

An automatic variable speed, self-adaptive technology, applied to components with teeth, transmission control, belt/chain/gear, etc., can solve the problems of short service life, high production cost, poor meshing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

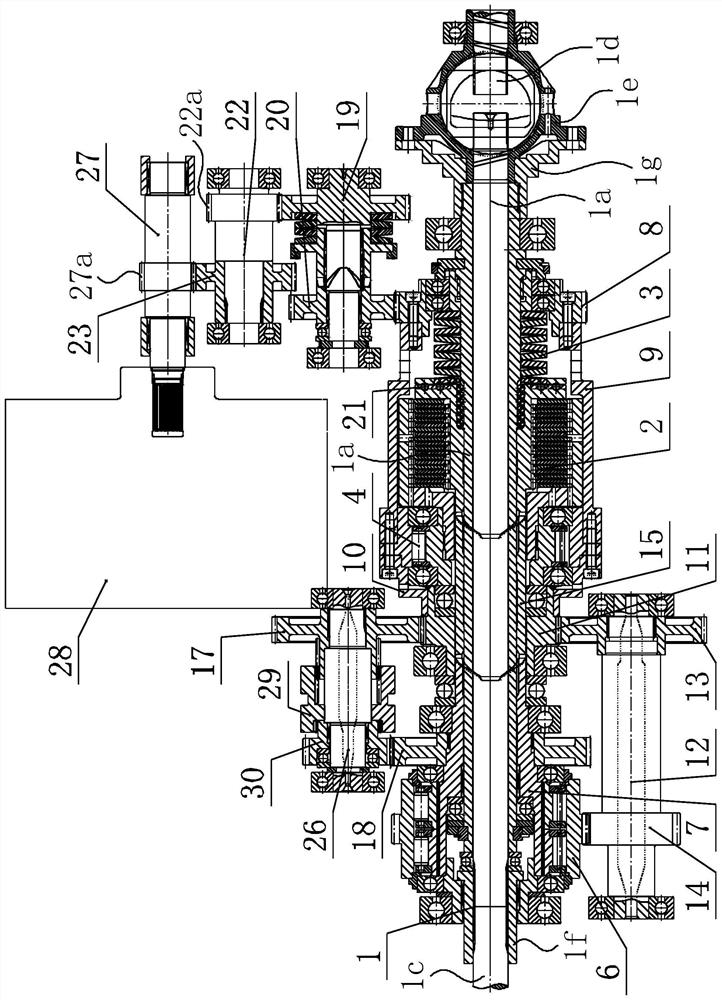

[0047] Such as figure 1 As shown, a large-load adaptive automatic transmission system capable of quick shifting is characterized in that it includes a power input mechanism, a high-speed gear transmission mechanism, a low-speed gear transmission mechanism, a reverse gear transmission mechanism, and a transmission bridge for outputting power 1 and a transmission sensing mechanism for detecting the resistive moment that the transmission axle 1 bears.

[0048] See figure 1 , the power input mechanism includes a motor 28, a motor output shaft 27 driven by the motor 28 and a power input shaft 22 parallel to the motor output shaft 27, the motor output shaft 27 has a power output tooth 27a, and the power input The shaft 22 is sleeved with a first-stage power driving gear 23 which rotates synchronously with it, and the first-stage power driving gear 23 meshes with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com