Fabricated screw rod assembly

A screw component and assembled technology, which is applied in the direction of construction and building construction, can solve the problems of construction workers such as waste of cost, improper disassembly, construction efficiency and economic benefits, and achieve the effect of eliminating the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

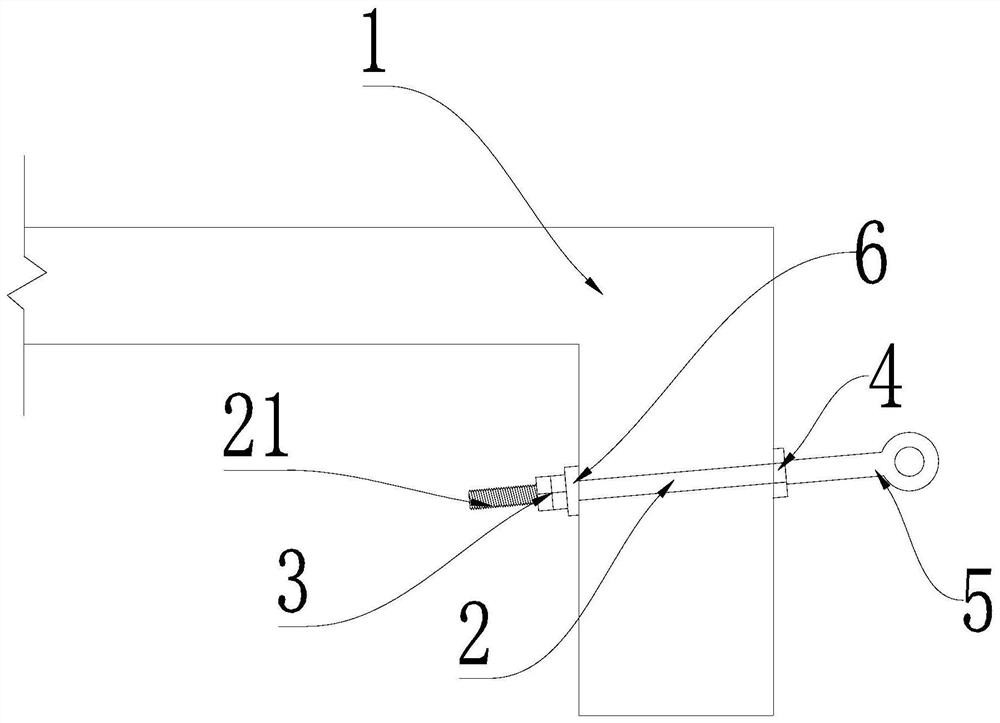

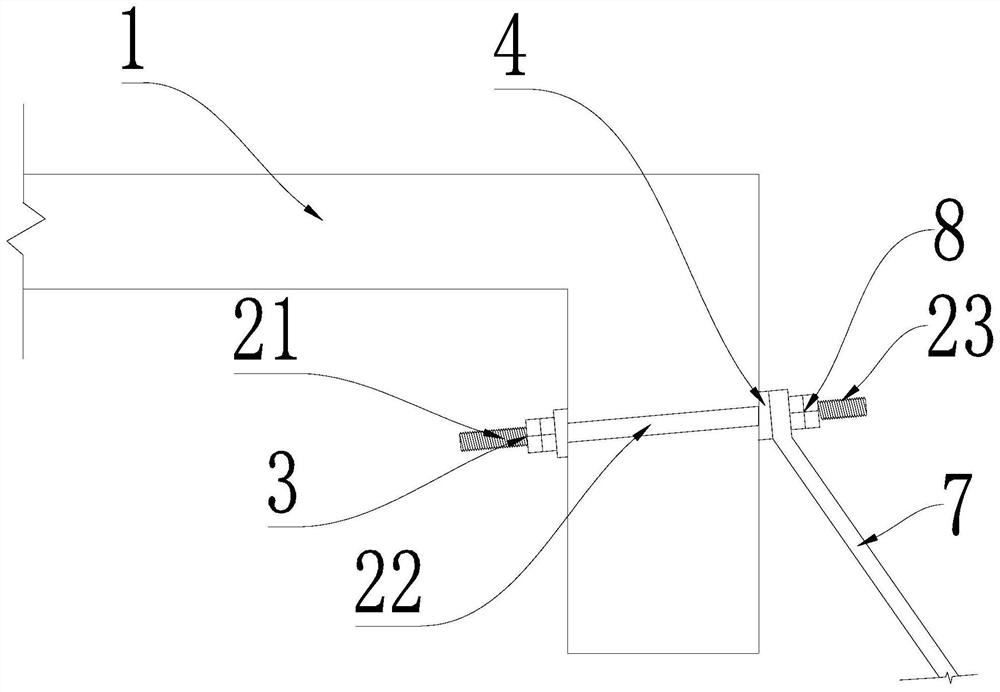

[0022] Example 1: See Figure 1 to Figure 5 , an assembled screw assembly in this embodiment includes a screw 2, a first threaded part 21 and a second threaded part 23 are respectively provided at both ends of the screw 2, and a useful thread is provided between the first threaded part 21 and the second threaded part 23 It is fixed on the support part 22 in the wall 1; it also includes a first fixing component adapted to the first threaded part 21 and a second fixing component adapted to the second threaded part 23, the first fixing component includes The first spacer 6 and the first nut 3 arranged on the part 22, the second fixing assembly includes the second spacer 4 and the lifting device arranged away from the support part 22, the first threaded part 21 and the second threaded part 23 The diameters are all smaller than the diameter of the support portion 22 . Pass the screw 2 through the pre-embedded hole, fix the screw 2 through the first fixing component and the second ...

Embodiment 2

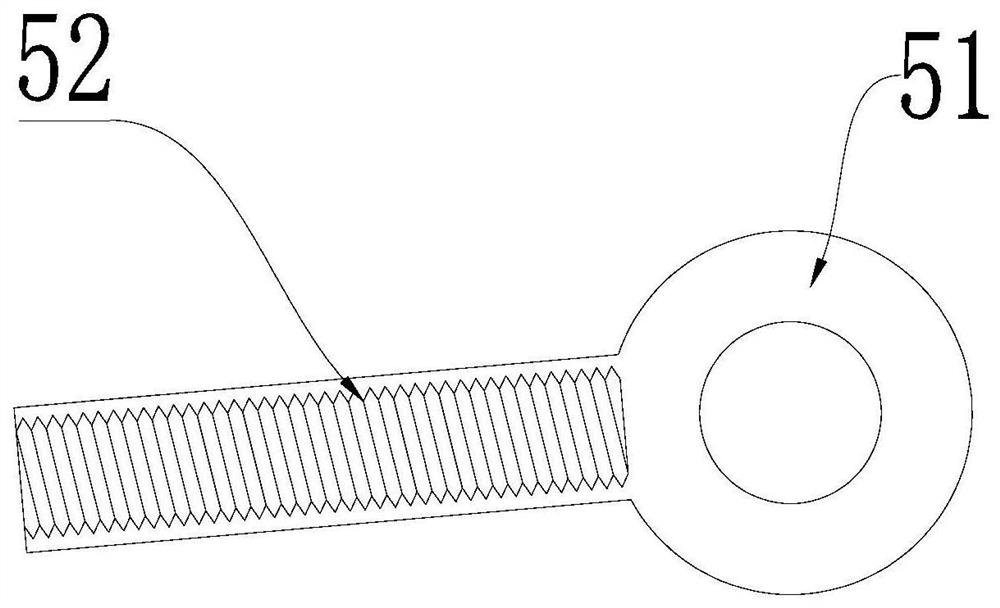

[0023] Embodiment 2: The support part 22 of this embodiment is arranged obliquely with the wall 1, the side of the first spacer 6 close to the wall 1 is provided with a first inclined fixing surface that fits the wall 1, and the second spacer 4 is close to the wall 1 One side of the wall 1 is provided with a second inclined fixing surface attached to the wall 1 . The screw assembly is installed obliquely and uses high-friction pads, so the force-bearing form is reasonable; the lifting ring 5 and the tie rod 7 are made of high-strength steel, and the force-bearing performance is better than that of the traditional anchor ring. The lifting assembly of this embodiment includes a lifting ring 5 , and the lifting ring 5 includes an integral internal thread sleeve 52 and a fixing ring 51 , and the internal thread sleeve 52 is adapted to the second threaded part 23 . The depth of the internal thread of the internally threaded sleeve 52 in this embodiment is not less than the length o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com