Method for preventing slag bonding of blast furnace refractory lining

A mud sleeve and slagging technology, applied to blast furnaces, blast furnace details, blast furnace parts, etc., can solve problems such as high safety risks of oxygen burning, difficult handling, and plugging failures, so as to eliminate the frequent phenomenon of plugging and reduce risks Hidden dangers, the effect of stability rate improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

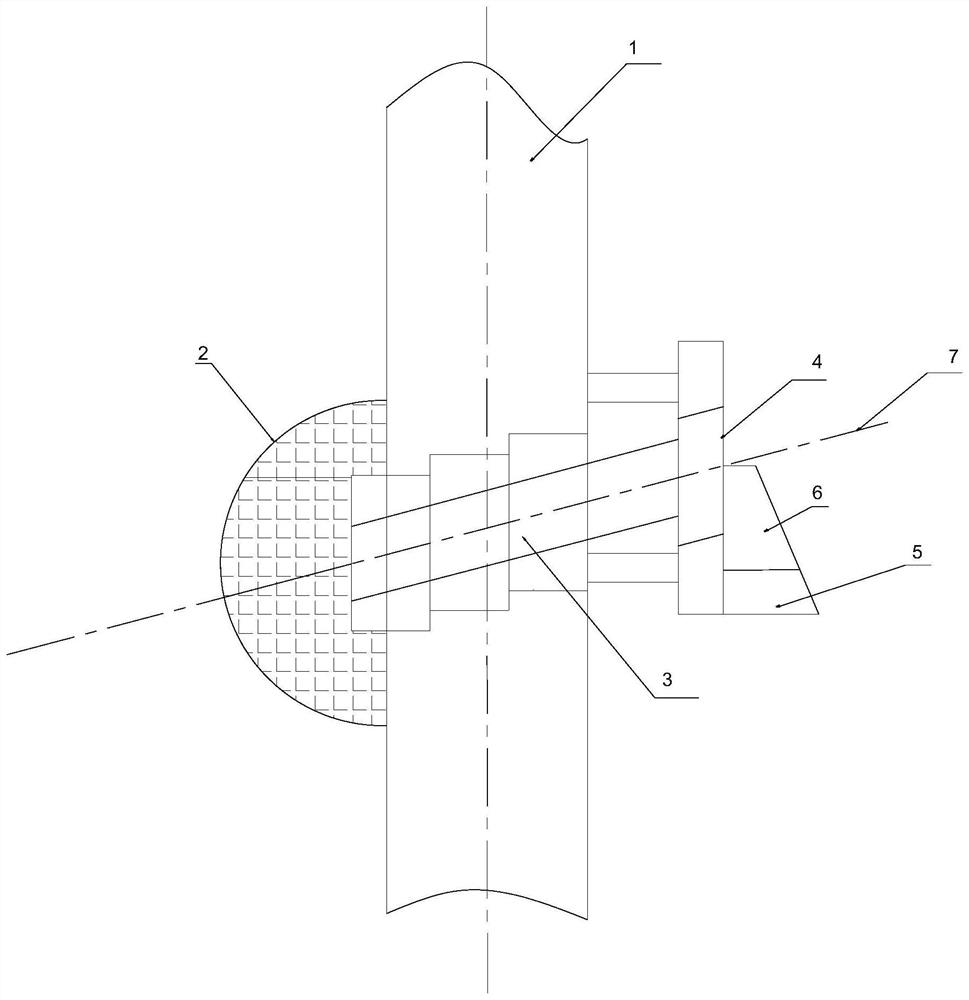

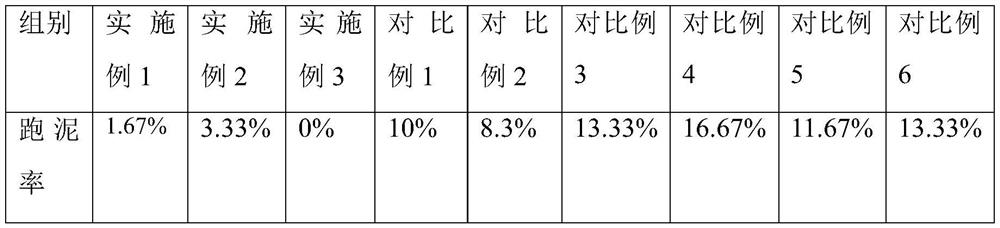

[0031] Example 1 A method for preventing blast furnace mud from slagging

[0032] The method includes the following steps:

[0033] S1. River sand and coke powder are mixed evenly according to the weight ratio of 8:0.5 and dried to obtain the protective material;

[0034] S2. Clean up around the mud jacket 4: After the hydraulic gun exits, clean up the slag iron, gun mud and other sundries around the iron mouth mud jacket, and ensure that the slag iron at the position 40cm in front of the mud jacket is cleaned;

[0035] Cleaning of the surface of the mud sleeve: After the hydraulic gun exits, the gun mud bonded on the surface of the mud sleeve is cleaned to ensure that the surface of the iron hole is flat. If the surface of the mud sleeve is damaged, it needs to be repaired and ground;

[0036] S3. laying one deck height is 3cm, and the insulation layer 5 that is 35cm is wide with sub-pack insulation agent at the periphery of mud cover;

[0037] S4. The protection material t...

Embodiment 2

[0040] Example 2 A method for preventing blast furnace mud from slagging

[0041] The method includes the following steps:

[0042] S1. River sand and coke powder are mixed evenly according to the weight ratio of 9:1.5 and dried to obtain the protective material;

[0043] S2. Clean up around the mud jacket 4: After the hydraulic gun exits, clean up the slag iron, gun mud and other sundries around the iron mouth mud jacket, and ensure that the slag iron at the position 70cm in front of the mud jacket is cleaned;

[0044] Cleaning of the surface of the mud sleeve: After the hydraulic gun exits, the gun mud bonded on the surface of the mud sleeve is cleaned to ensure that the surface of the iron hole is flat. If the surface of the mud sleeve is damaged, it needs to be repaired and ground;

[0045] S3. be 15cm in laying one deck height around the mud cover with subpackage insulation agent, the insulation layer 5 that is 60cm wide;

[0046] S4. The protection material that step S...

Embodiment 3

[0049] Example 3 A method for preventing blast furnace mud from slagging

[0050] The method includes the following steps:

[0051] S1. River sand and coke powder are mixed evenly according to the weight ratio of 9:1 and dried to obtain the protective material;

[0052] S2. Clean up around the mud jacket 4: After the hydraulic gun exits, clean up the slag iron, gun mud and other sundries around the iron mouth mud jacket, and ensure that the slag iron at the position 60cm in front of the mud jacket is cleaned;

[0053] Cleaning of the surface of the mud sleeve: After the hydraulic gun exits, the gun mud bonded on the surface of the mud sleeve is cleaned to ensure that the surface of the iron hole is flat. If the surface of the mud sleeve is damaged, it needs to be repaired and ground;

[0054] S3. it is 8cm to lay one deck height around the mud cover with subpackage insulation agent, and the insulation layer 5 that is wide is 45cm;

[0055] S4. The protection material that st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com