Forklift driving type large-scale glass calibration and installation semi-automatic device and using method thereof

A driving, semi-automatic technology, applied in the direction of lifting devices, building materials processing, construction, etc., can solve the problems of inconvenient control, high manual labor intensity, time-consuming and labor-intensive, etc., and achieve reasonable structural design, low manual labor intensity, and accurate The effect of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] See attached picture.

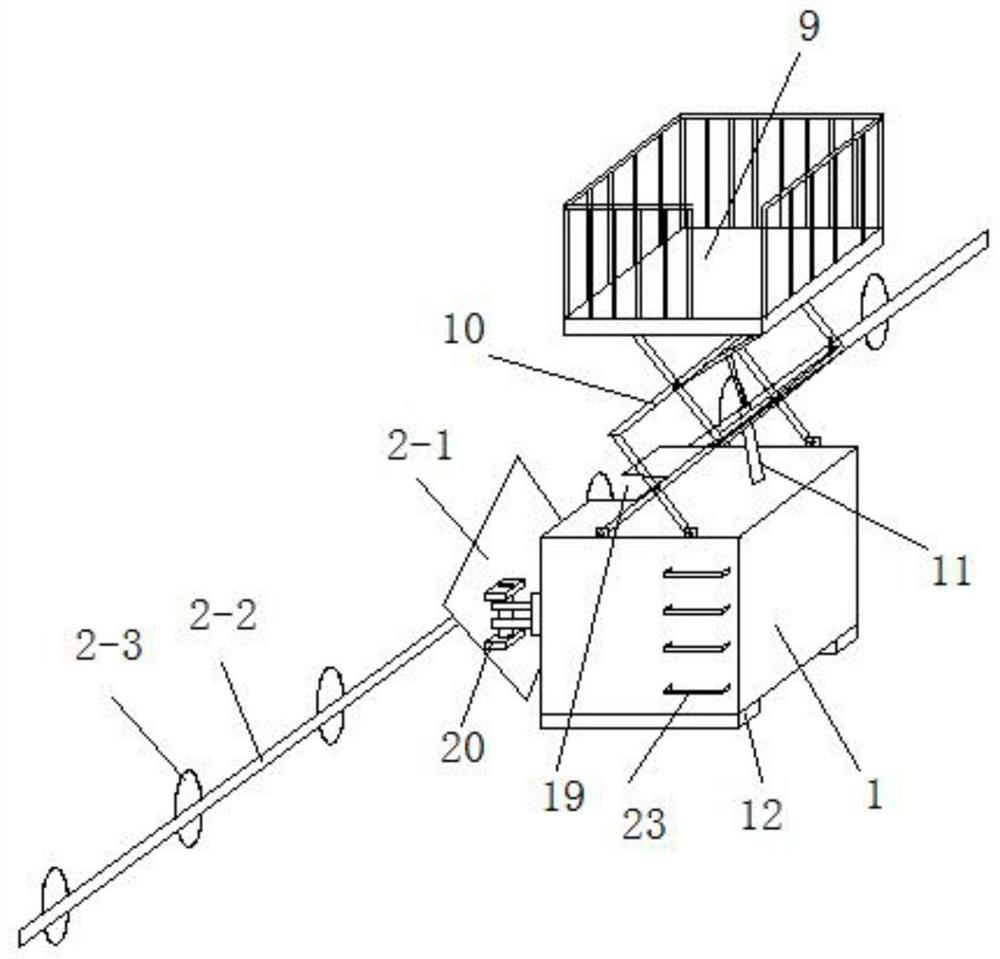

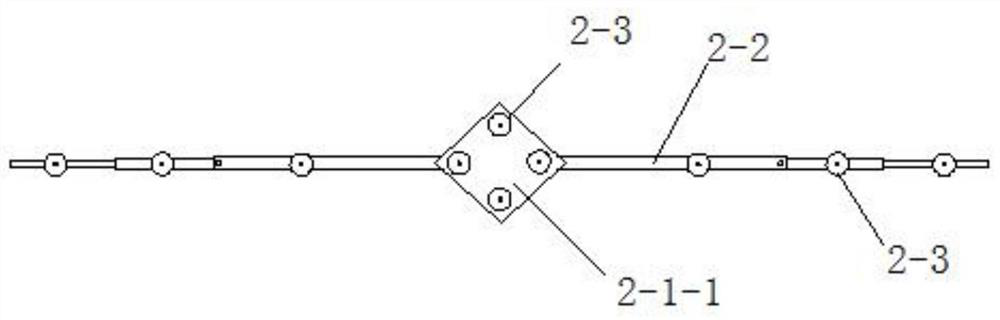

[0028] A forklift-driven large-scale glass calibration and installation semi-automatic device, including a fixed seat 1, the front mounting frame of the fixed seat 1 is provided with a suction cup assembly 2, the suction cup assembly 2 includes a suction cup fixed seat 2-1, two parts of the suction cup fixed seat 2-1 Side bar 2-2 is installed on the side respectively, and suction cup fixed seat 2-1 comprises the fixed plate 2-1-1 of rear end portion and the rotating seat 2-1-2 of front end portion, and rotating seat 2-1-2 passes rotating shaft The rotation is installed on the fixed disk 2-1-1 and the relative position between them is connected and fixed by a bolt. The fixed disk 2-1-1 is equipped with suction cups 2-3 respectively in the up, down, left, and right directions, and the side bars 2-2 are distributed with Suction cups 2-3 are arranged at intervals, and the middle part of the fixed seat 1 is provided with a hollow cavity, and the norma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com