A drive wheel independent damping structure of an agv drive assembly

A driving assembly and driving wheel technology, applied in the direction of vehicle springs, elastic suspensions, vehicle components, etc., can solve the problems of AGV body unable to lift synchronously, unable to provide axial buffering, AGV tipping, etc., to increase thickness, ensure Stability, the effect of increasing the load-bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

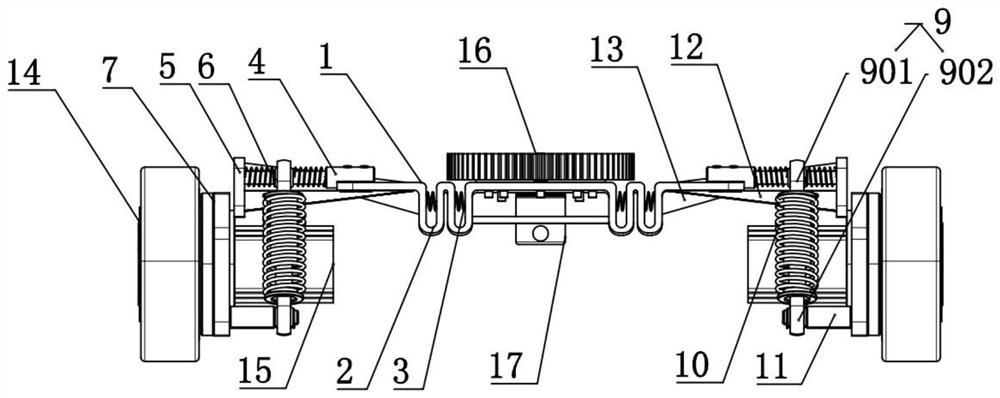

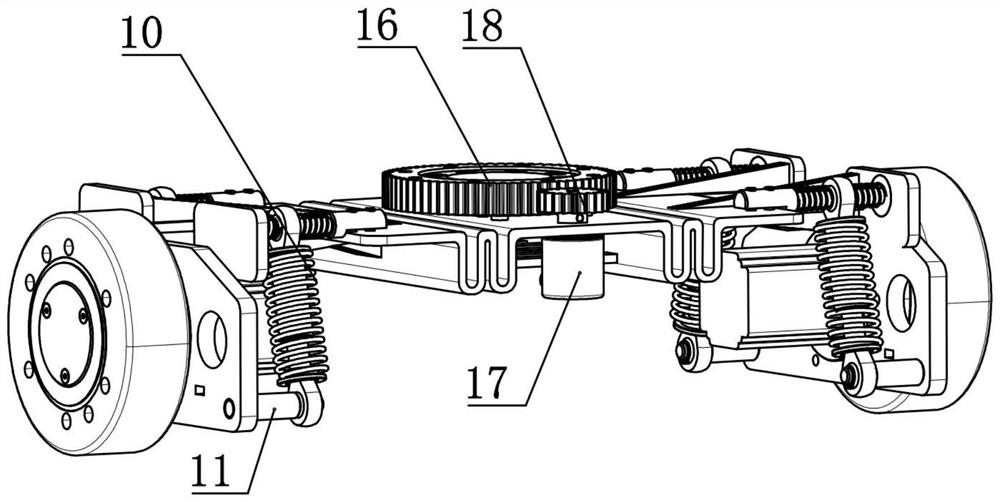

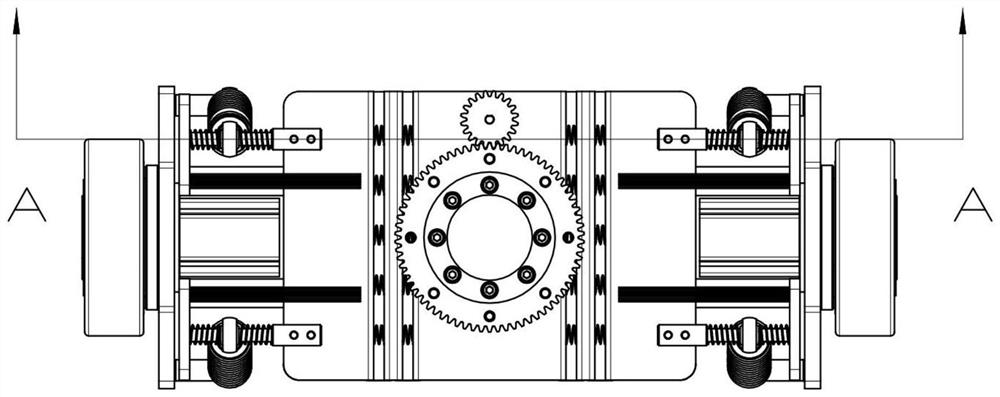

[0029] A drive wheel independent damping structure of an AGV drive assembly, refer to Figure 1-Figure 6 As shown, it includes a support plate 1 fixedly connected to the bottom plate 8 of the AGV body, a drive plate 7 positioned on both sides of the support plate 1, a drive wheel 14 mounted on the drive plate 7, and a first motor 15 that drives the drive wheel 14 to rotate, The driving wheel 14 is rotationally connected with the driving plate 7 through a rotating shaft, the first motor 15 is fixed on the inner surface of the driving plate 7, the first motor shaft is fixedly connected with the rotating shaft, and a fixed connection with the base plate 8 is arranged on the upper end surface of the support plate 1 for rotation. The driven gear 16 is provided with a driving gear 18 meshing with the driven gear 16 on the support plate 1, and a second motor 17 that drives the driving gear 18 to rotate is fixed on the lower end surface of the support plate 1. When the controller recei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com