A water supply system for milling based on precision CNC machine tools

A technology of milling and precision numerical control, applied in metal processing equipment, metal processing mechanical parts, milling machine equipment, etc., can solve the problems of poor spray effect and inconvenient adjustment, save space, reduce waste, and improve spray effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

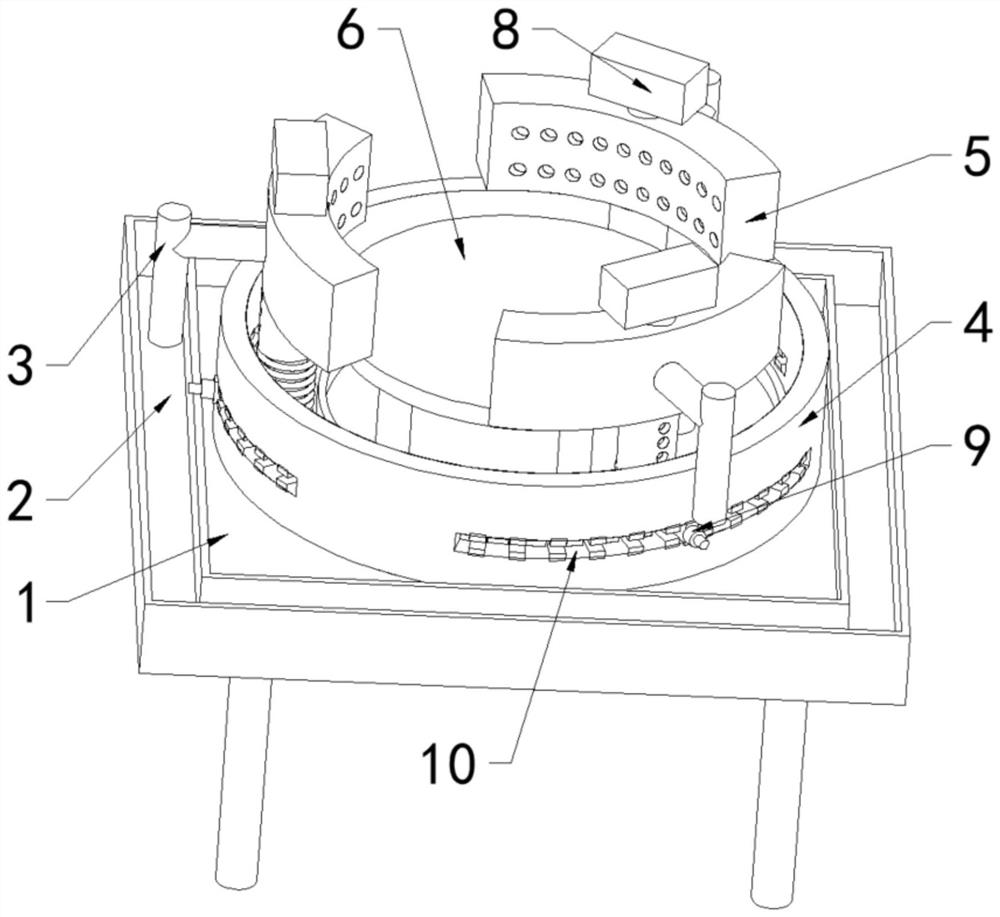

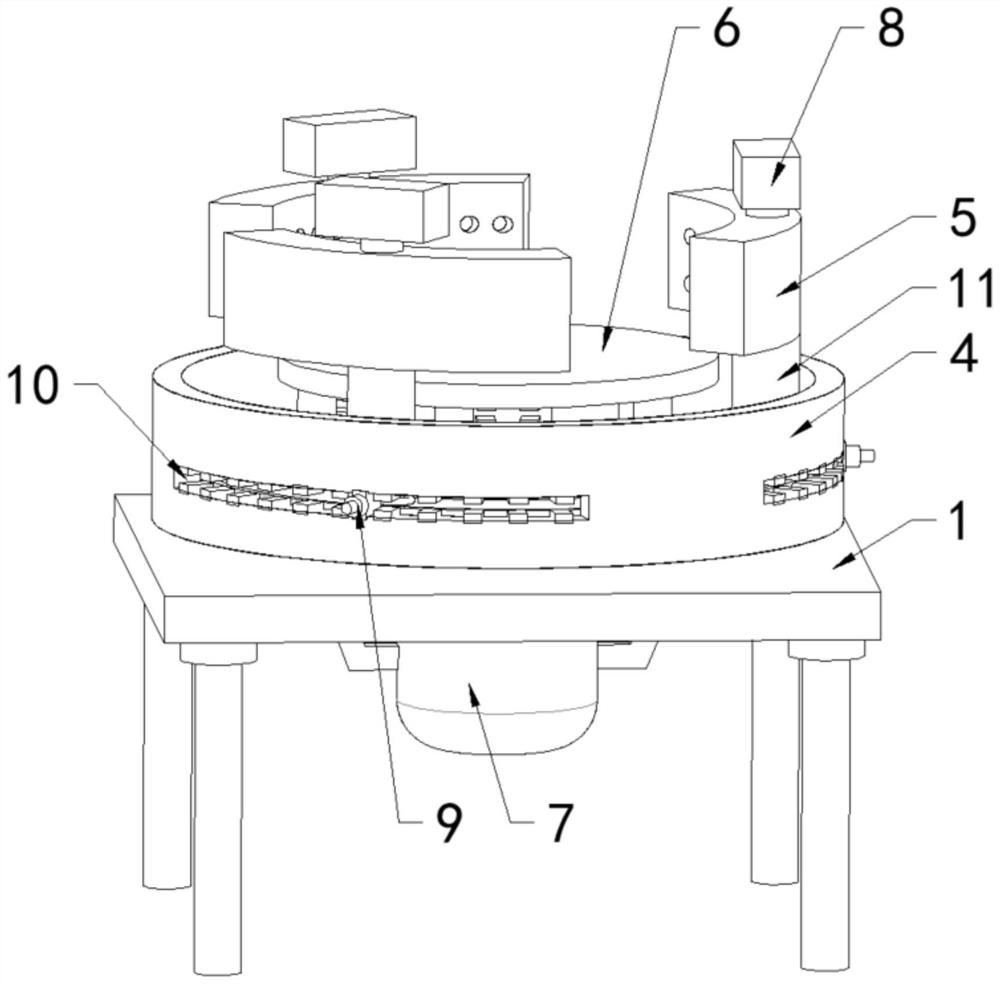

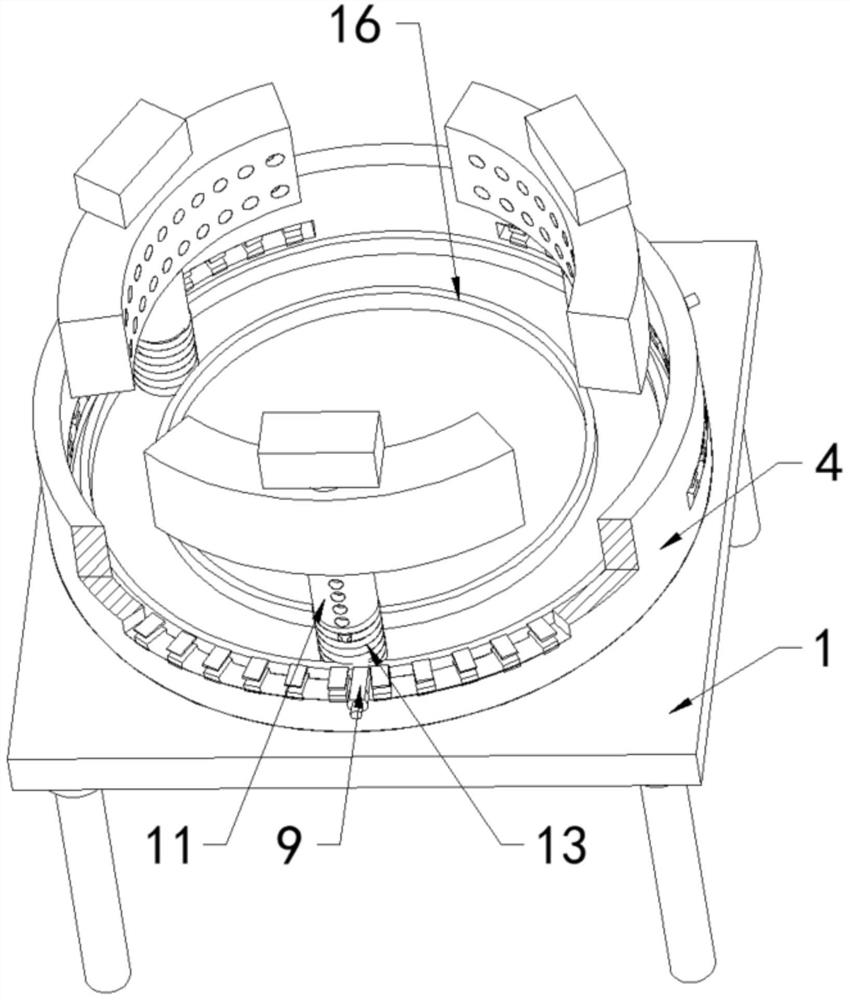

[0036] Such as Figure 1-7 As shown, a water supply system based on precision CNC machine tool milling, including a workbench 1, a rotating sleeve 4 is installed on the top of the workbench 1, a milling table 6 is installed inside the rotating sleeve 4, and the outer ring of the milling table 6 is The array is provided with at least three water spray boxes 5, and the bottoms of the at least three water spray boxes 5 are connected to the rotating sleeve 4 through a telescopic assembly to define the vertical height of the water spray box 5, and the side of the rotating sleeve 4 The end face is provided with movable slots 10 for at least three water spray boxes 5 to move in an arc shape, and the movable slots 10 are set in the limit assembly 9 to limit the horizontal arc-shaped movement position of the telescopic assembly. The water storage tank 2, and at least three water spray tanks 5 are connected with the upper water pipe 3 that can be selectively communicated with the water ...

Embodiment 2

[0040] Such as Figure 1-7 As shown, a water supply system based on precision CNC machine tool milling, including a workbench 1, a rotating sleeve 4 is installed on the top of the workbench 1, a milling table 6 is installed inside the rotating sleeve 4, and the outer ring of the milling table 6 is The array is provided with at least three water spray boxes 5, and the bottoms of the at least three water spray boxes 5 are connected to the rotating sleeve 4 through a telescopic assembly to define the vertical height of the water spray box 5, and the side of the rotating sleeve 4 The end face is provided with movable slots 10 for at least three water spray boxes 5 to move in an arc shape, and the movable slots 10 are set in the limit assembly 9 to limit the horizontal arc-shaped movement position of the telescopic assembly. The water storage tank 2, and at least three water spray tanks 5 are connected with the upper water pipe 3 that can be selectively communicated with the water ...

Embodiment 3

[0044] Such as Figure 1-7 As shown, a water supply system based on precision CNC machine tool milling, including a workbench 1, a rotating sleeve 4 is installed on the top of the workbench 1, a milling table 6 is installed inside the rotating sleeve 4, and the outer ring of the milling table 6 is The array is provided with at least three water spray boxes 5, and the bottoms of the at least three water spray boxes 5 are connected to the rotating sleeve 4 through a telescopic assembly to define the vertical height of the water spray box 5, and the side of the rotating sleeve 4 The end face is provided with movable slots 10 for at least three water spray boxes 5 to move in an arc shape, and the movable slots 10 are set in the limit assembly 9 to limit the horizontal arc-shaped movement position of the telescopic assembly. The water storage tank 2, and at least three water spray tanks 5 are connected with the upper water pipe 3 that can be selectively communicated with the water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com