Environment-friendly welding fume purifier

A welding fume and purifier technology, applied in the direction of dust removal, indirect heat exchangers, chemical instruments and methods, etc., can solve problems such as inability to absorb smoke and dust, affect wind passage, and high-temperature damage to pipelines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

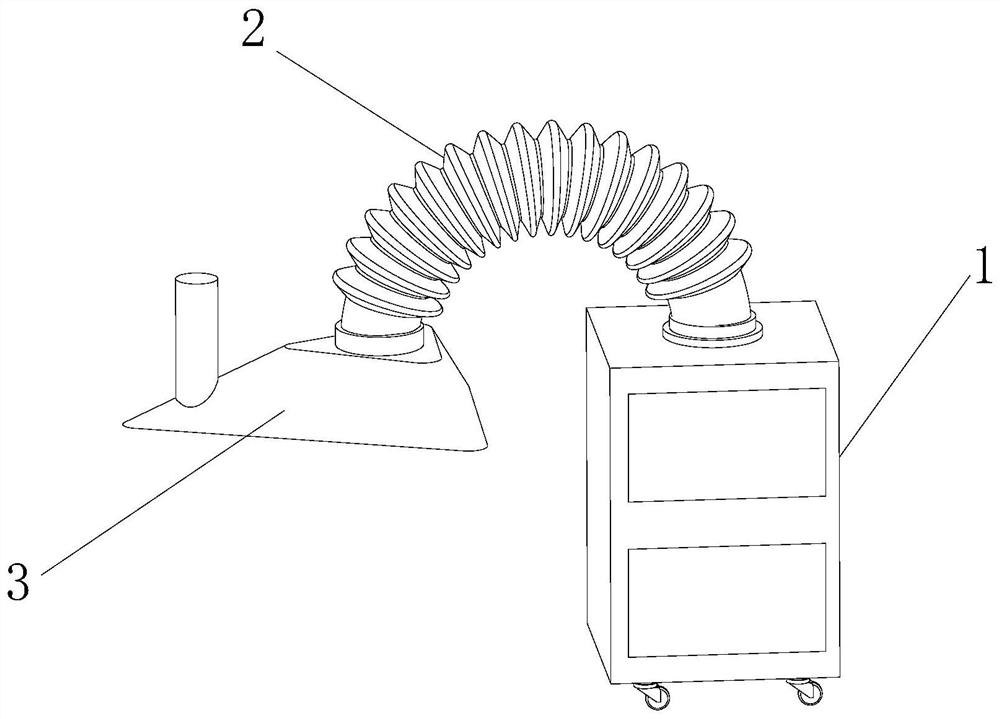

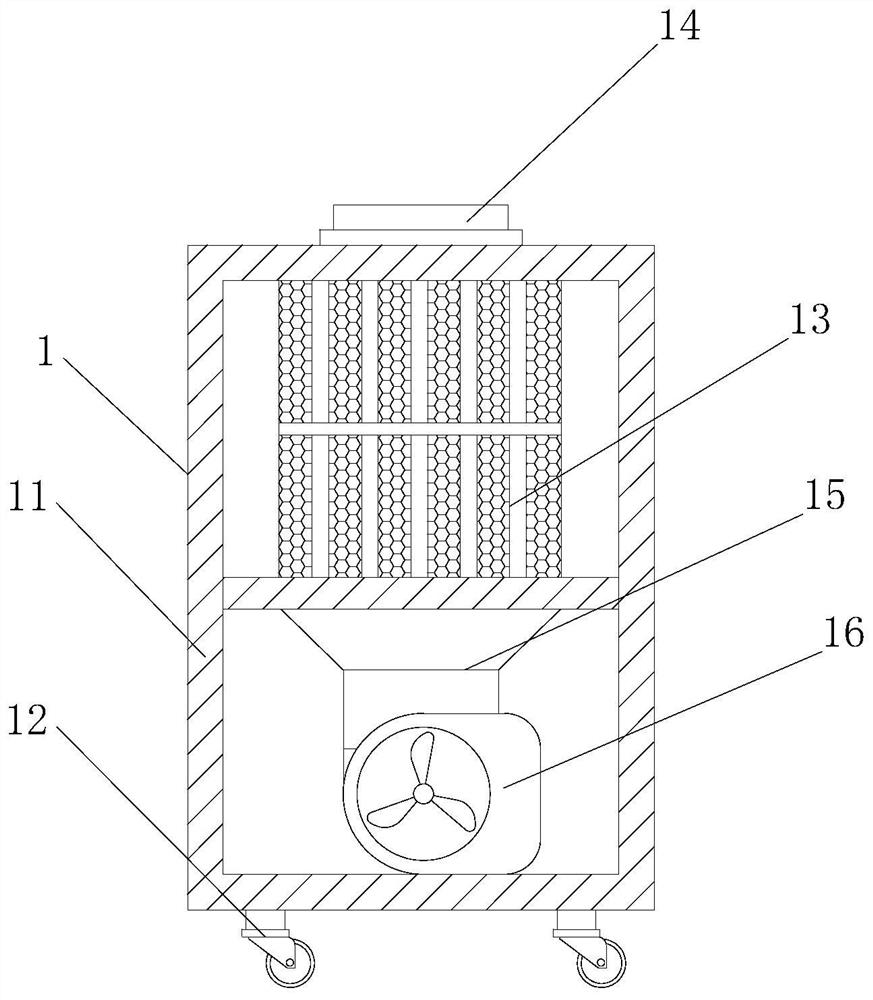

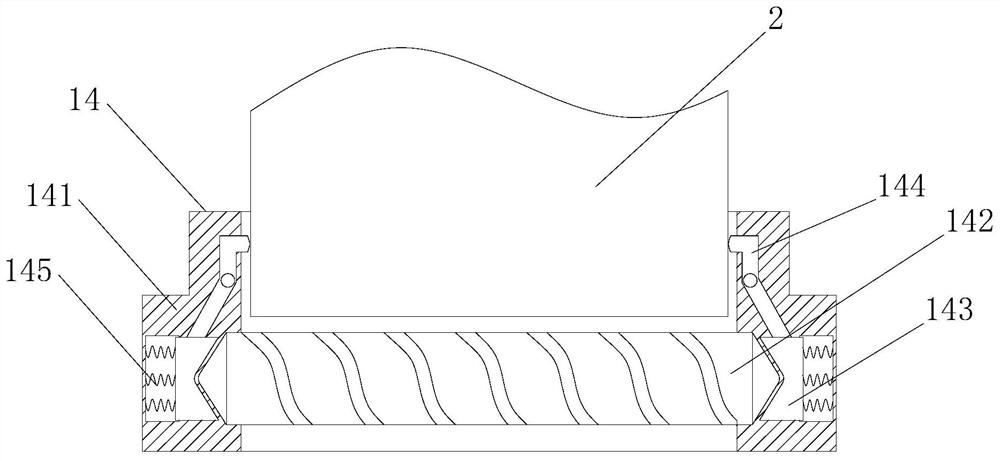

[0028] Such as Figure 1-Figure 3 As shown, the present invention provides an environment-friendly welding fume purifier, comprising a main box body 1, a universal dust suction hose 2 is arranged above the main box body 1, and one end of the universal dust suction hose 2 is connected to the main box The top of the body 1 is fixedly connected, the other end of the universal suction hose 2 is fixedly connected with a dust collection cover 3, the main box body 1 includes a casing 11, and the bottom surface of the casing 11 is fixedly equipped with mutually symmetrical universal wheels 12, the casing 11 The top of the top is fixedly connected with a connecting piece 14. By using the combination of the universal suction hose 2 and the connecting piece 14, it can be realized that when the air flow passes through the connecting piece 14, the wind deflecting wheel 142 is driven to rotate, so that the slider 143 and the wind guiding wheel The outer wall of 142 constantly collides, and ...

Embodiment 2

[0030] Such as Figure 4-8As shown, on the basis of Embodiment 1, the present invention provides a technical solution: the dust suction hood 3 includes a cover body 31, the inside of the cover body 31 is provided with a cooling device 33, the top of the cooling device 33 and the inner wall of the cover body 31 Fixed connection, the top of the cooling device 33 is fixedly connected with a filter block 34, and the combination of the cover body 31, the cooling device 33, and the filter block 34 is used to facilitate the use of smoke and dust from the cover body 31 when it is sucked into the universal vacuum hose 2. After passing through the cooling device 33, the smoke and dust will absorb heat through the surface of the air deflector 3312. The ceramic connecting rod 3314 can quickly transfer the heat absorbed by the air deflector 3312 to the air, so that the air deflector 3312 can keep the low temperature and continue to cool down. The cooled smoke and dust will enter the air in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com