Crushing tooth assembly and crusher

A technology of crushing teeth and crushers, which is applied in the direction of grain processing, etc., can solve the problems of insufficient space for cutting motors and cable troughs, high maintenance costs for crushers, and inability to transport conveyors, etc., to solve the problem of power source, Save installation space, low manufacturing cost and low use cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

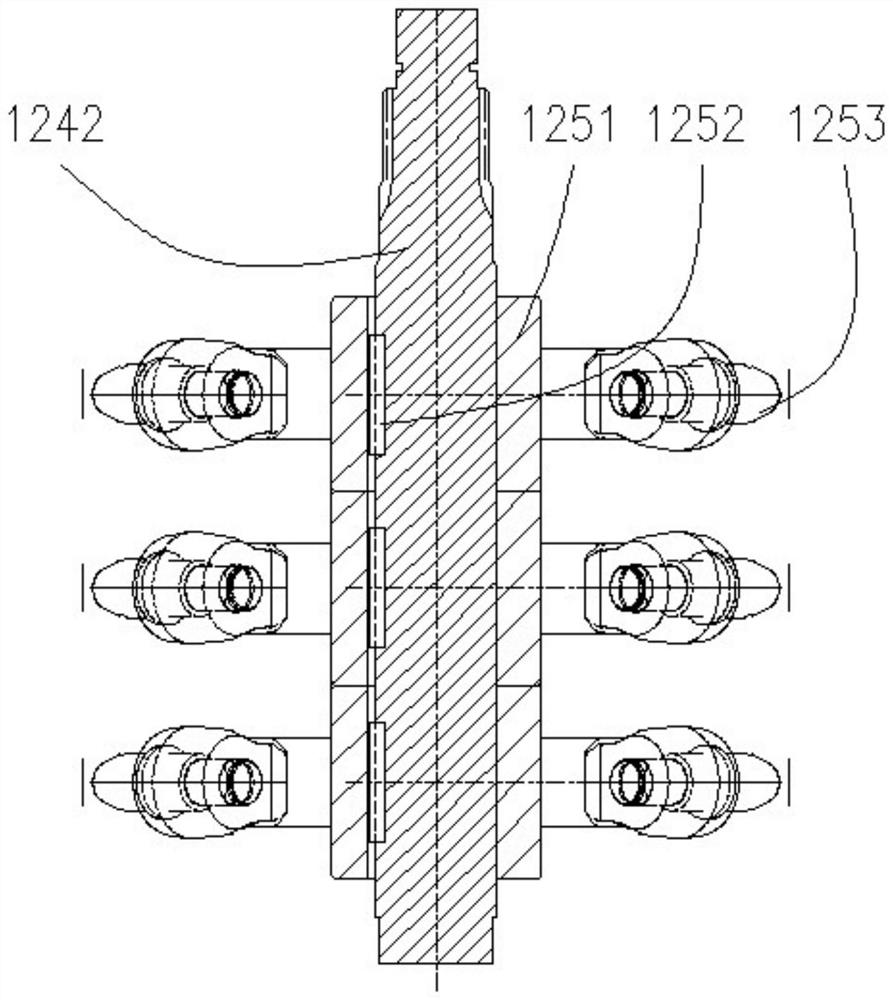

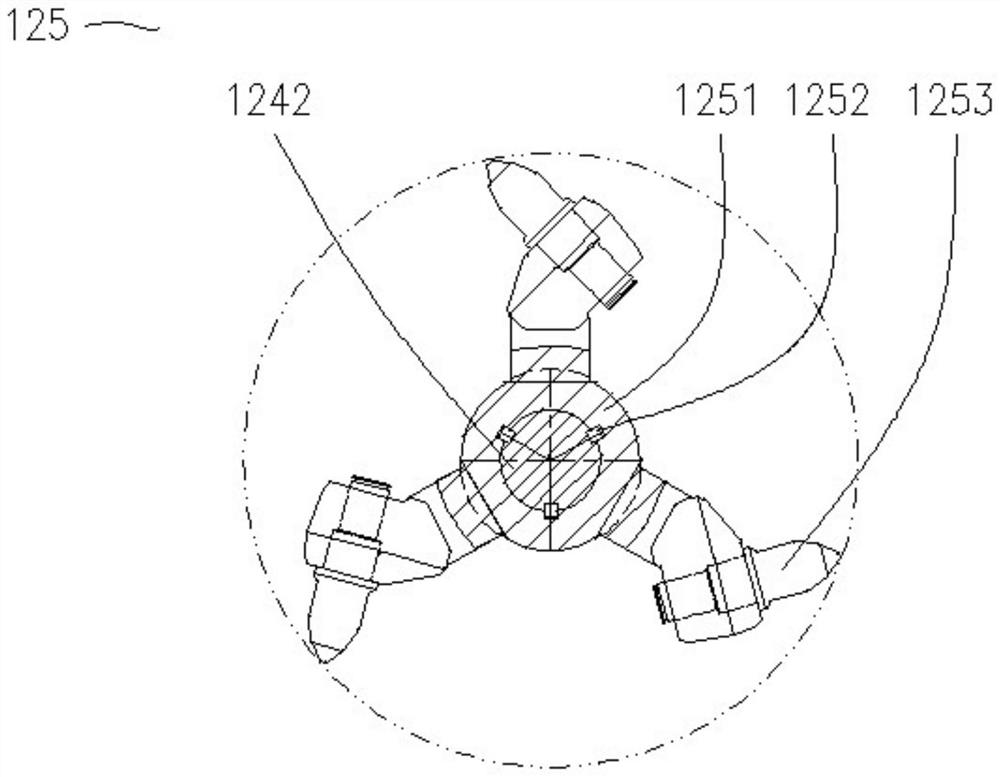

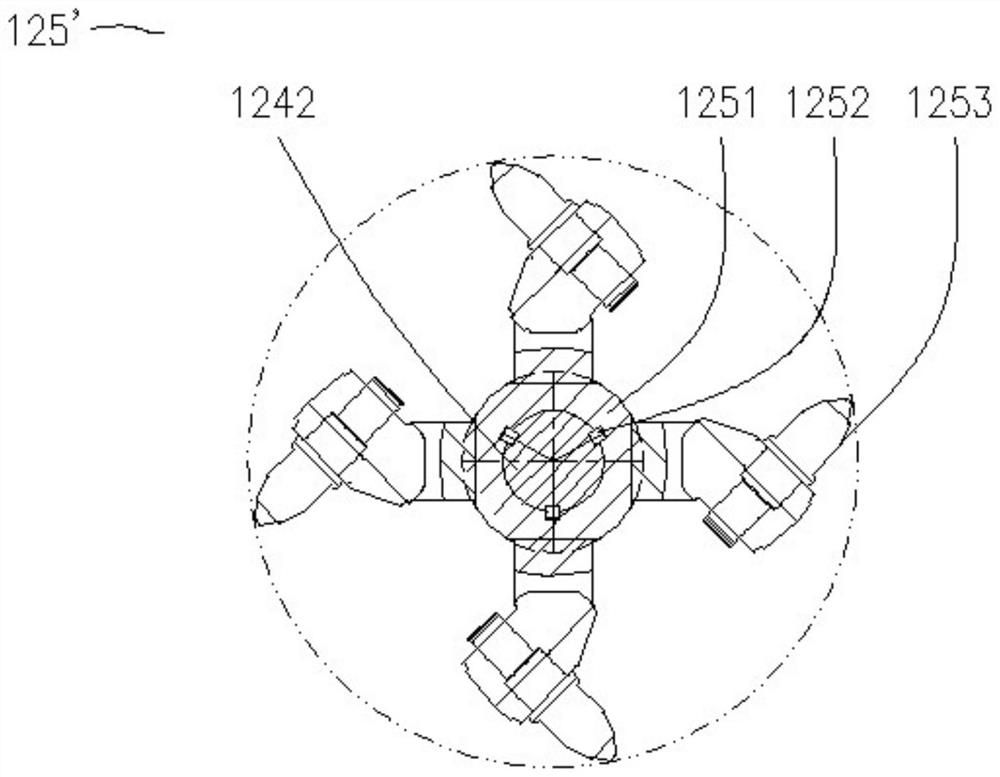

[0035] The invention discloses a crushing tooth assembly, such as Figure 1-7 As shown, it includes a connecting shaft 1242 and several crushing tooth groups 125, each of which includes a shaft sleeve 1251 and a plurality of crushing teeth 1253 fixed on the outer periphery of the shaft sleeve. The crushing tooth can be installed on the shaft sleeve through the crushing tooth seat. Each crushing tooth seat is equipped with a crushing tooth, and all the crushing teeth are installed in a clockwise or counterclockwise direction. The shaft sleeve and the connecting shaft of the group are connected by a plurality of flat keys 1252, and the multi-position flat keys are evenly distributed in the circumferential direction, the circumferential fixing is reliable, and the axial assembly and disassembly of the shaft sleeve is convenient. When a crushing tooth is damaged, it is only necessary to replace the crushing tooth and the shaft sleeve where it is located, and the maintenance is si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com