Self-heating methanol reforming hydrogen production reactor

A technology for reforming hydrogen production and reactor, applied in the field of hydrogen production devices, can solve the problems of hydrogen production economy and convenience of use discount, catalyst sintering failure, unfavorable scale enlargement, etc., and achieves good preheating effect and strong functionality. , the effect of high energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below with reference to the accompanying drawings and specific examples.

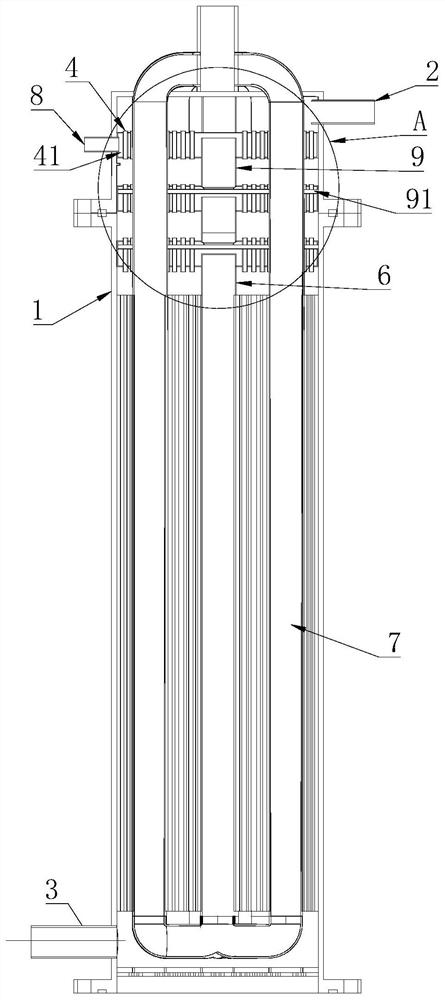

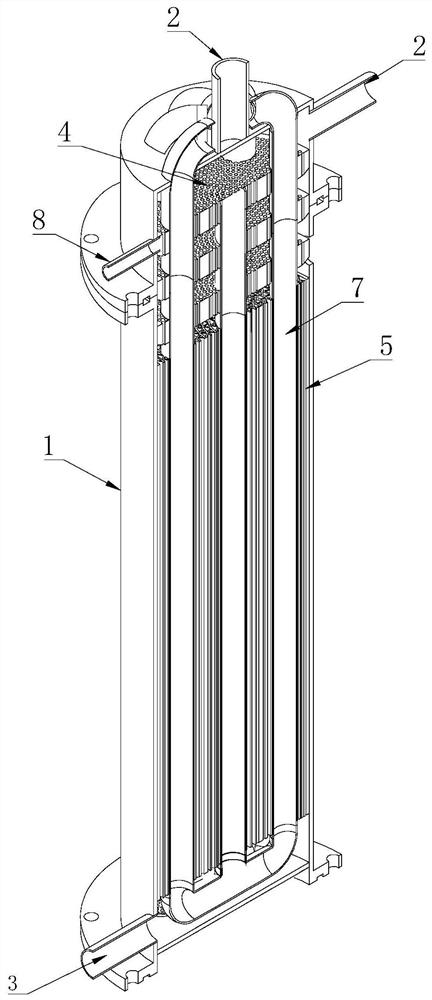

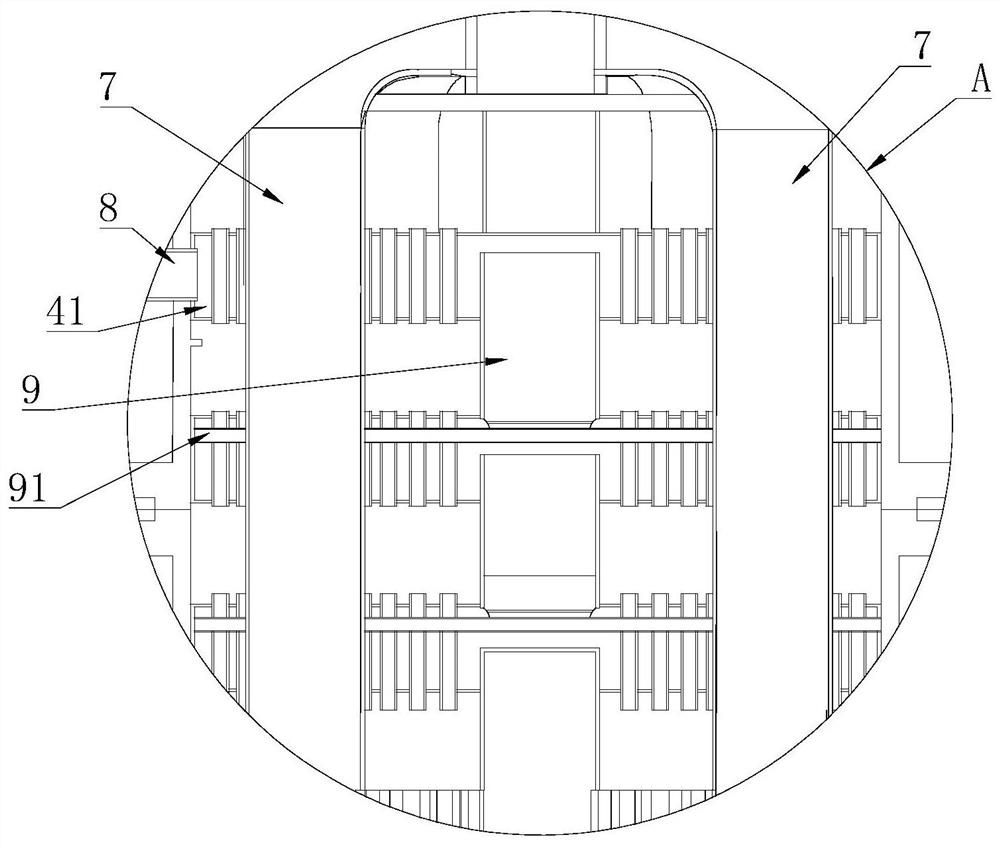

[0026] See Figure 1-5 As shown, a self-heating methanol reforming hydrogen reactor comprising a reactor body 1, the reactor body 1 is provided with a preheating chamber and a reaction chamber, the preheating chamber Airport 2, the reaction chamber is provided with a fuel inlet 3;

[0027] The preheating chamber is provided with a first honeycomb carrier 4, and the reaction chamber is provided with a second honeycomb carrier 5, the second honeycomb carrier 5, is facing a conductive tube 6 and a number of retentate 7, The conduit tube 6 is in communication with a plurality of retent pipe 7, and several of the weight pipe 7 extends through the first honeycomb carrier 4 outside the reactor body 1, the first honeycomb carrier 4 has a heat exchange chamber 41, and the heat exchange chamber 41 communicates with the reforming feedstock inlet 8 and the conduit t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com