Three-dimensional toilet seat cushion and manufacturing method and using method thereof

A manufacturing method and technology of a toilet seat, applied to the seat or cover of the toilet, applications, household appliances, etc., can solve the problems of insufficient response, and achieve the effects of avoiding cold touch, stabilizing height, and stabilizing adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Hereinafter, embodiments of the present invention will be described based on the drawings.

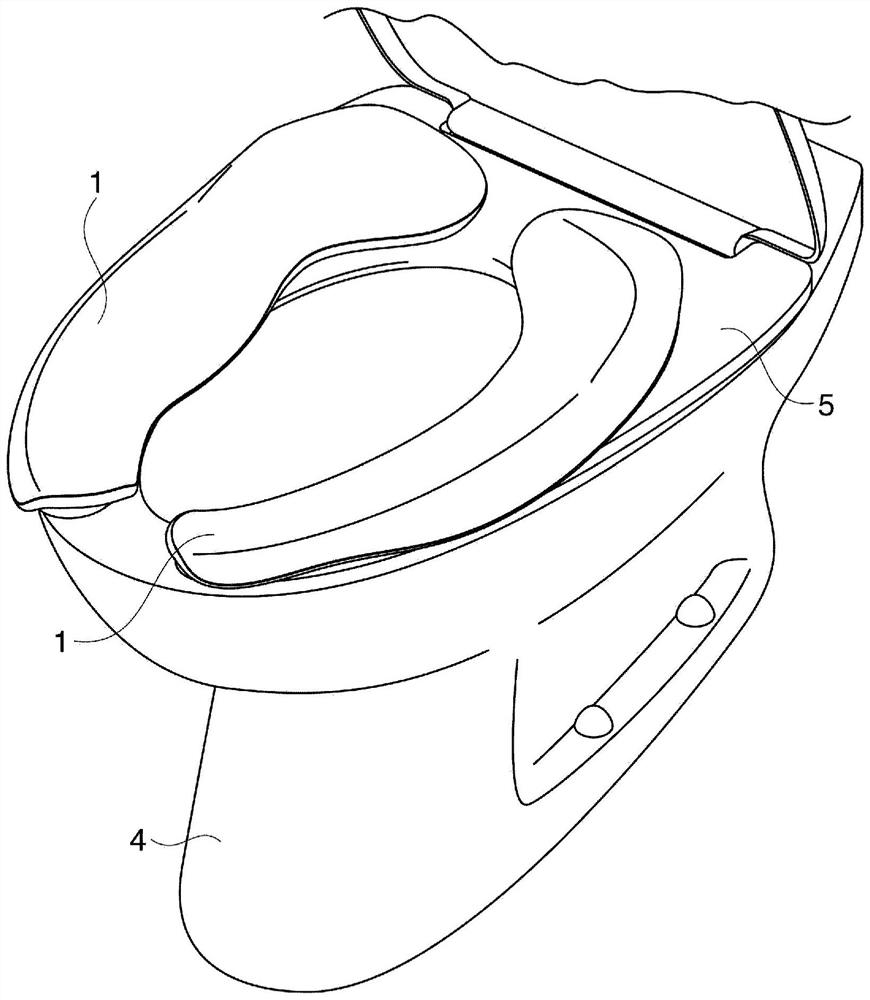

[0045] Such as figure 1 As shown, the toilet seat 1 is symmetrically formed as a pair, mounted on the toilet seat 5 at the upper end of the toilet 4 for use, and arranged so as not to interfere with the operation of the cleaning nozzle (not shown).

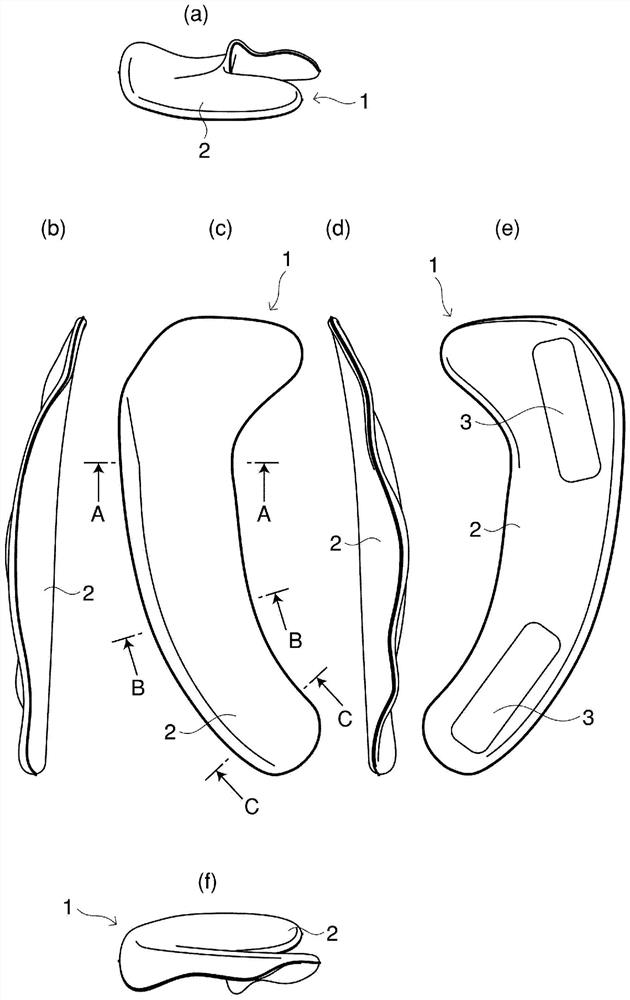

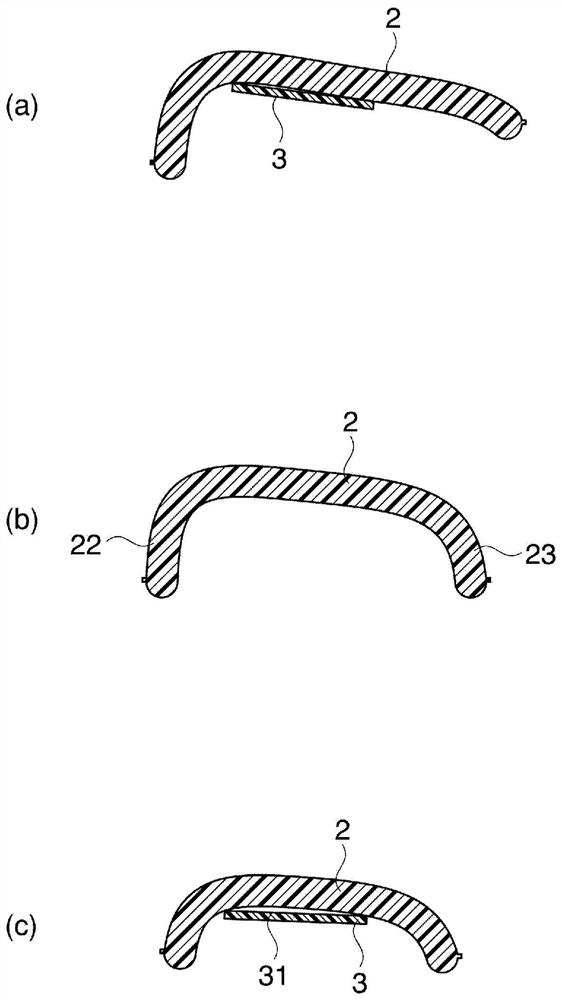

[0046] Such as Figure 2 to Figure 5 As shown, the toilet seat cushion 1 includes a deformed crescent-shaped main body 2 and a fixing part 3 for assembling on the toilet seat. as from figure 2 As clearly seen in each figure of , the toilet seat 1 is three-dimensional, and is attached to the toilet seat 5 so as to cover and follow the three-dimensional shape of the toilet seat 5 . Conspicuous rising portions (the outer rising portion 22 and the inner rising portion 23 ) are formed on both sides in the longitudinal direction of the main body 2 . All contours of the toilet seat are made of curved surfaces, and there are no straig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive stress | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com